Dra. Enara Mardaras

«Buscamos desarrollar aleaciones y componentes más resistentes a entornos de trabajo hostiles, mediante procesos de transformación y tratamientos más eficientes y sostenibles.»

CORROSIÓN Y PROTECCIÓN DE MATERIALES

Surface modification of a cast iron with spheroidal graphite using duplex Steel

The improvement of the corrosion resistance of spheroidal graphite iron (FGE) has been achieved through

Estudio de la resistencia a la corrosión de recargues con mezcla de polvo realizados mediante LMD

Este estudio se lleva a cabo con el objetivo de demostrar la factibilidad del empleo

Influence of graphite morphology on electrochemical corrosion behaviour in cast irons

Cast irons are widely used in the automotive industry due to its excellent castability, fluidity,

Simulation of hydrogen transport in ultra-high strength martensitic steels with zinc-nickel coating

-No hay información- Autores/as: A. Ravikumar (Helmholtz-Zentrum Hereon), C. Feiler (Helmholtz-Zentrum Hereon), D. Höche (Helmholtz-Zentrum

Influence of graphite morphology on the corrosion behaviour of cast irons for automotive industry

Cast irons are widely used in the automotive industry due to its excellent castability, fluidity,

Study of the corrosion behavior of CRA cladded high strength steel for offshore service

Components subjected to corrosion in the Oil & Gas sector are frequently manufactured in Corrosion

Influence of the casting process on corrosion behaviour of 2024-T6 aluminium alloy in different conditions of pH and NaCl concentration

Corrosion behaviour of 2024-T6 castings produced by sand mould and metallic mould has been studied

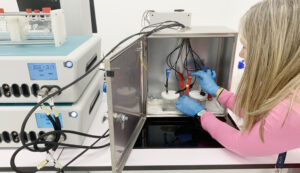

Permeación de Hidrógeno

desarrollo de materiales PERMEACIÓN Y FRAGILIZACIÓN POR HIDRÓGENO Desarrollo de materiales y recubrimientos más resistentes