-

Congreso

Alloys for Additive Manufacturing Symposium 2023

-

Fecha de presentación

09/2023

-

Tags

Ana Fernandez, Garikoitz Artola, I+D+i, Meshind, Polvos metálicos, Tecnologías de conformado, Unai Garate

El objetivo principal de este trabajo es fabricar y probar un polvo L-DED a medida para mejorar la resistencia al desgaste de las herramientas de conformado tras la aplicación de revestimiento láser en las áreas requeridas. El desgaste de los aceros para herramientas sigue siendo una gran preocupación en las tecnologías de conformado, debido al aumento de los costes de mantenimiento de las matrices y las tasas de desperdicio consecuencia de las severas tensiones tribológicas y los estrictos límites de tolerancia de este tipo de componentes [1]. La dureza se utiliza comúnmente en la práctica industrial para la selección de materiales relacionados con el desgaste [2]. Sin embargo, fabricar matrices completas con aceros para herramientas con propiedades mejoradas y excelente resistencia al desgaste presenta la desventaja de un aumento de los costes. Por lo tanto, para superar estas limitaciones, la tecnología de fabricación por deposición directa de energía láser (L-DED) cobra fuerza y parece ser una solución potencial para su aplicación sobre un sustrato de acero para herramientas común.

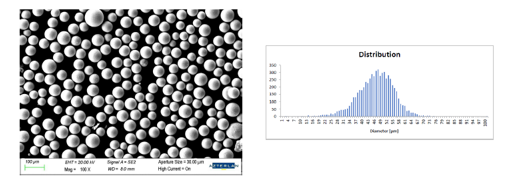

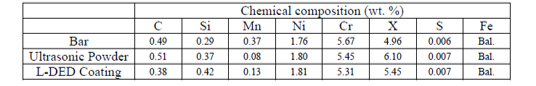

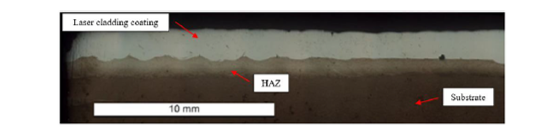

El objetivo principal es desarrollar un polvo personalizado para su aplicación mediante L-DED con dureza mejorada, gracias a la formación de diferentes carburos duros. El metal con la composición química objetivo se fundió en un pequeño horno piloto de 50 kg en Azterlan. Se fundieron varios bloques de quilla y se mecanizaron barras de Ø 8 mm. El contenido de Cr fue de ~5,5 % en peso, y la suma del otro promotor de carburos, el contenido de X, fue de ~5 % en peso. Estas barras se atomizaron luego mediante el atomizador ultrasónico de polvo metálico ATO Lab+, utilizando el módulo de 35 kHz. Se obtuvo un polvo muy esférico, típico de la atomización ultrasónica de polvo metálico (véase la Figura 1), siendo D10 = 42 μm, D50 = 51 μm y D90 = 62 μm. La Tabla 1 muestra que se produjo un desvanecimiento significativo de Mn (~78 %) en comparación con la composición química de la barra analizada mediante ICP-OES y LECO, mientras que los demás elementos se enriquecieron en consecuencia. Este polvo fue depositado por MESHIND, utilizando una máquina L-DED Trumpf TruLaserCell 3000, en una muestra cuadrada de una sola capa con un espesor entre 1,5-2,1 mm y buena unión metalúrgica con el sustrato (Figura 2). Se observaron pocos poros en el recubrimiento, siendo el más grande de 0,2 mm. La Zona Térmicamente Afectada fue pequeña con un espesor entre 0,5-1,2 mm. Además, la tasa de dilución es pequeña, la composición química del recubrimiento está ligeramente enriquecida en Mn en comparación con la composición del polvo (véase la Tabla 1), mientras que C se reduce debido a la dilución con el acero base 1.2344. Se observan varios carburos complejos en el análisis de la microestructura, con una dureza del recubrimiento 15 HRC mayor que la del sustrato.

Como conclusión principal, se ha demostrado que la metodología propuesta es útil para la fabricación de matrices revestidas, pero es necesario aumentar el contenido de Mn durante la fabricación de la barra para compensar la pérdida de masa durante el proceso de atomización y así lograr el contenido y la composición química deseados en el recubrimiento. La dureza del revestimiento en estado bruto es de 54 HRC y podría utilizarse sin tratamientos de posprocesamiento.

Autores/as:

Oier Barrenetxea (AZTERLAN), Unai Garate (MESHIND, Metal Stamping Hot Industry), I. Shubin (3D Lab Sp. z o. o.), Ana Isabel Fernández-Calvo (AZTERLAN).

Keywords:

Herramienta de troquelado, atomizado de polvos metálicos, desvanecimiento de manganeso, revestimiento láser, fortalecimiento de superficies.