Ferrita-perlita transformazio-denbora murrizteko estrategia lineako tratamendu termikoan, espazio mugatuko forjetan

-

Argitalpena

ECHT 2024 & A3TS 50th Congress

-

Aurkezpen data

2024/06

-

Tags

Amaia Natxiondo, B+G+i, Garikoitz Artola, Itziar Berriozabalgoitia, Konformatze Teknologiak

Hot forged steel parts frequently need to be submitted to a heat treatment after the forming operation. Normalizing is extremely common since it allows grain size refining and softens the material for subsequent machining operations. The most common operating procedure for performing this heat treatment is separating it from the forging operation by means of an intermediate stock.

The intermediate stocking is done by piling the forged parts in containers straight from the forging line. The whole container is left to cool down until the parts reach room temperature by natural cooling. The containers are afterwards fed to a batch heat treating furnace for normalizing. This approach leads to several inefficiencies. A significant amount of waste heat is lost in part cooling both from forging temperature and normalizing temperature. Besides that, heat treating by batches implies longer dwell times and energy consumption than part-by-part heat treatment, as the container needs to be heated and the parts in the center of the stock achieve the heat treatment setpoint temperature. Logistic costs must also be considered since they increase proportionally to the distance from the forge to the heat treatment facility.

Current trends in Green Manufacturing applied to heat treatment technology are a driving force for avoiding these inefficiencies. In-line heat treatment in continuous furnaces, which are placed right after the forging operation, is employed to reduce these wastes. Unfortunately, most of the forging workshop layouts were not designed thinking on in-line heat treatment and the available space is scarce. For a given part geometry and forging production rate, the space available in the layout determines furnace length and width and, thus, the maximum in-line heat treatment time. This means that the time available for performing the microstructural transformations that are sought in the heat treatment is extremely limited and in certain cases new approaches are required.

This is the case of 18CrNiMo6-7 steel, which is used in forged parts. A regular in-line austenite to ferrite-pearlite isothermal transformation would take over two hours to complete, so in general it requires long furnaces and a broad layout space. The heat treatment temperature is selected so that ferrite-pearlite nucleation and growth are balanced, and transformation time is minimized. The temperature corresponds to the tip of the ferrite nose of the temperature-transformation-time curve (TTT).

Ferrite and pearlite nucleation are enhanced below this balance temperature and inhibited beyond it. Their growth acts exactly opposite, being faster at high temperatures and slower blow the nose tip. This manuscript explores an approach that takes advantage of this behavior to reduce in-line treatment time. First the 18CrNiMo6-7 is taken slightly over the martensite start temperature for a dwell time shorter than that required for the beginning of bainite transformation. This aims to generate a wealth of ferrite nuclei. Immediately after this, the temperature is raised so that atom diffusivity is increased to promote the growth of those nuclei.

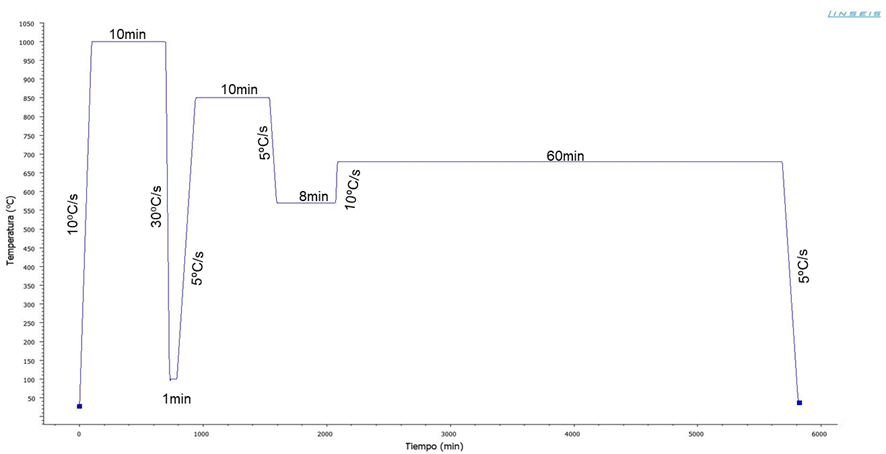

A dilatometry experiment was performed to assess the effectiveness of the proposed approach. The dilatometric cycle simulated a forge in-line heat treatment with two furnaces. The simulated process required first a quick grain size recovery, performed with direct water quenching from the forging press and immediate austenitizing for 10 minutes at 850ºC in the first furnace. The accelerated ferrite-pearlite transformation was simulated for the second furnace. The parts are fed to second furnace after a forced air cooling to conditioning of the part to a temperature of 570ºC. This temperature is held for 8 minutes for nuclei generation and a final ramp up to 680ºC for one hour is aimed to nuclei growth. Figure 1 shows thermal profile of the dilatometer programming.

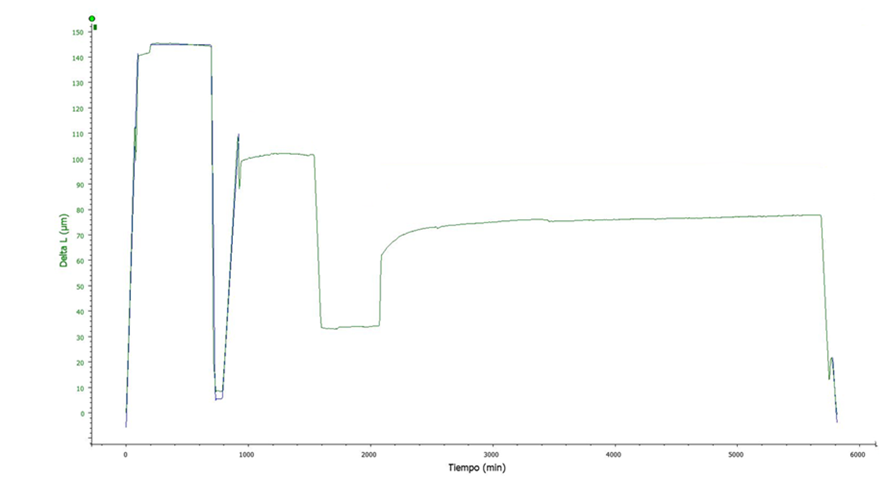

The experimental data obtained by dilatometric testing has shown this approach to be effective in shortening the heat treatment time. Microstructural transformation speed is accelerated thanks to the generation of nuclei at a temperature below the TTT’s ferritic transformation nose followed by a temperature increase to promote diffusion. The expansion in the specimen (Figure 2) indicates that the ferrite-pearlite transformation is very quick right after the temperature rise from the nuclei generation plateau. It is noticeable that enormous time saving, and thus layout occupation reduction, potentials can be obtained. E.g. the dwell time at 680ºC is ineffective transformation-wise after 10 minutes.

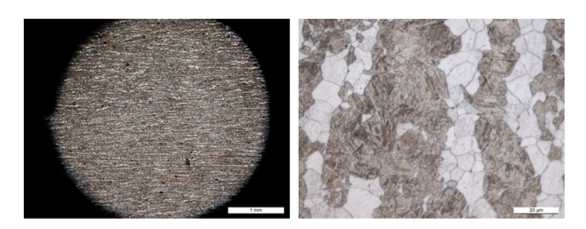

Despite refined ferritic-pearlitic structures (Figure 3) and hardness values below 300 HV were achieved with this heat treatment approach, ongoing work is aimed to further shorten cycle time and furnace sizes and also to eliminate the final residual martensitic expansion noticed at the final cooling.

Autoreak:

Amaia Natxiondo, Itziar Berriozabalgoitia, Garikoitz Artola

Keyword-ak:

lerroko tratamendu termikoa, forjaketa-beroa, bero hondarrak aprobetxatzea, energia efizientzia.