AZTERLAN

Knowledge Hub

Aurkitu AZTERLANeko lan-taldeak sortutako teknologiak, materialak eta diseminazio ekintzak.

Zeren bila zabiltza?

Garapenak eta gaitasunak:

Diseminazioa

High Performance Materials for extreme Energy Intensive Industry Process Environments

Modified cast austenitic alloys have been designed to enhance the creep strength of rollers and beams of a

Kasandra®: Nucleation and solidification modelization of iron alloys for process control in real time

Nowadays, Foundry industries struggle to keep the competitiveness of their technology by means of more efficient processes. New technologies

Access the mechanical and thermal fatigue in packed bed thermal energy storage concept

The thermocline Thermal Energy Storage (TES) systems are key elements to boost renewable energies and to improve the

SMART CASTING® – As cast osagaien fabrikazioa

Burdin-galdaketa SMART CASTING® Ekidin balio erantsi txikiko akabera-eragiketak. Eragiketa gutxiago, eraginkorrago. “Lead time to market”

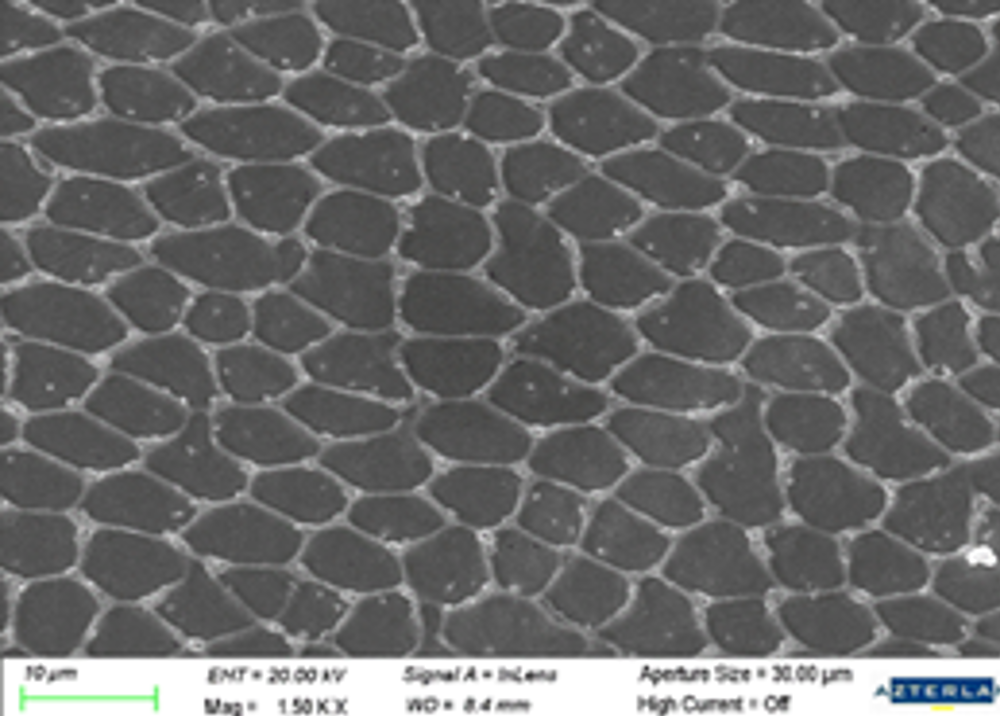

Influence of the Chemical Composition on the Solidification Path, Strengthening Mechanisms and Hardness of Ni-Cr-Si-Fe-B Self-Fluxing Alloys Obtained by Laser-Directed Energy Deposition

Nickel-based Ni-Cr-Si-B self-fluxing alloys are excellent candidates to replace cobalt-based alloys in aeronautical components. In this work, metal

Korrosioarekiko eta/edo higadurarekiko erresistentzia handiagoa duen burdinurtuzko zati bat sortzeko metodoa, eta metodo horren bidez lortutako burdinazko osagarria

A method for producing a cast iron part comprising: a) obtaining a reactive paint comprising at least one

New EoL Routes of Al-Li Aircraft Integral LBW and FSW Welded Panels including New Cr-Free Coatings

The end of fife (EoL) of new aircraft panels made of Al-Li alloys in which the stringers and

Embedded conductors in solidified molten metal for winding packs for high-field stellarators

The potential advantages of high-field stellarators are currently being recognised, as previously happened with tokamaks. However, the winding

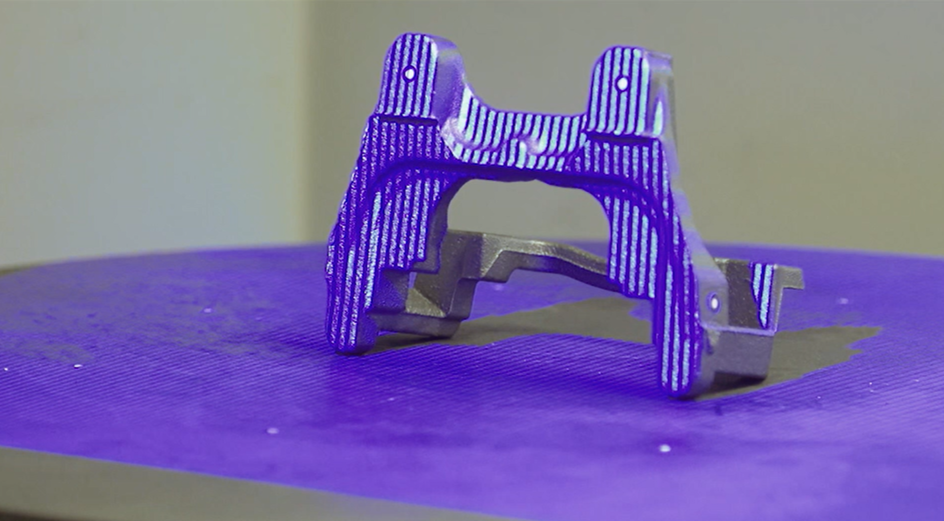

Obtaining Perfect Critical Automotive Safety Components through Behavioral Monitoring and Simulation using Digital Twins

With the aim of obtaining the perfect component and manufacturing process without defects or claims, an ecosystem of

Evolution of the Metallurgical Quality of Spheroidal Graphite Iron during the Thermal Cycle of the Melt: Furnace – Ladle – Heating/Pouring Unit

The final properties of a ductile iron and its nucleation potential are determined by the different processes undergone

Itsas-korrosioarekiko erresistenteak diren osagaiak, CRA estalduren bidez

Korrosioarekiko erresistenteak diren aleazioak, edo CRA (Corrosion Resistant Alloys), fenomeno horren aurrean dituzten propietateengatik dira ezagunak, eta asko

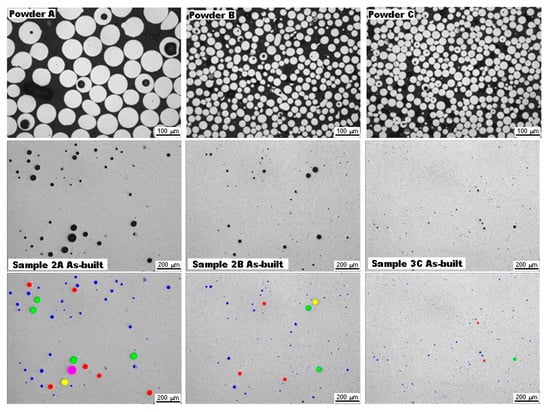

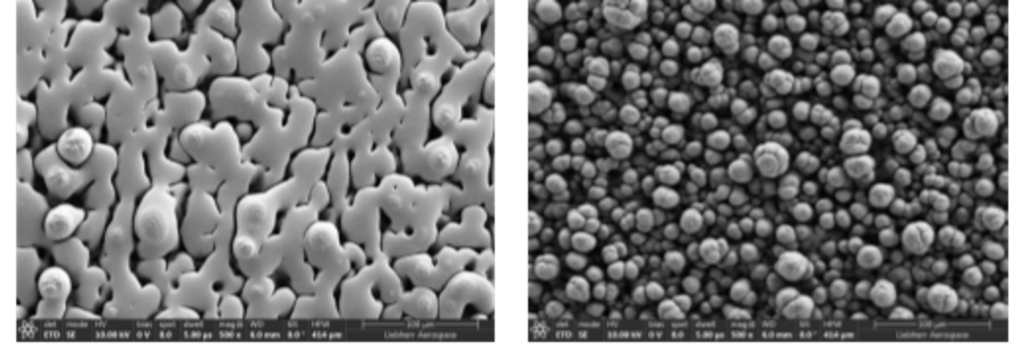

On the Mechanism of Formation of Bimodal Grain Structure in Al–4.5Mg–0.7Sc–0.3Zr Alloy Processed by Laser Powder Bed Fusion

Scalmalloy is an Al–Mg alloy with additions of Sc and Zr originally developed as a high-strength aluminum alloy

Damping behaviour of high silicon nodular cast iron

This work focused on producing and characterizing high silicon cast irons (microstructural analysis, tensile properties, damping capacity, elastic

Influencia del recubrimiento Zn-Ni en la resistencia del acero 300M estimada mediante Small Punch Testing

Egindako azterketaren helburu nagusia da Zn-Ni estaldura erabiltzea bideragarria den egiaztatzea, bai eta deshidrogenatze-prozesua burutzeko parametroak mugatzea ere.

Finkapen-elementuak

ESPEZIALIZAZIO-EREMUA Hari bidez finkatzeko elementuak Torloju, azkoin, zirritu eta multzo hariztatuen kalitatea eta ezaugarritzea. 3.1 eta 3.2 ziurtapen-saiakuntzak

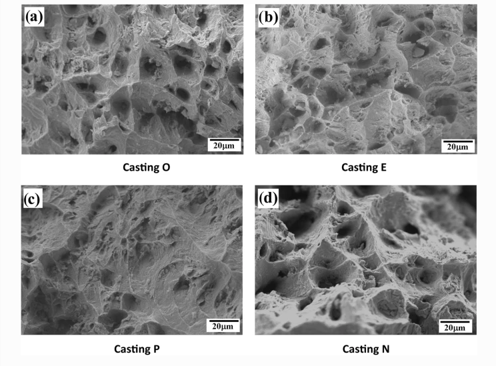

Effects of Different Si Content and Thermal Stories on the Secondary Phase Formation, Hot Ductility, and Stress Rupture Properties of Alloy 718 Investment Castings

Herein, the effects of microstructure on high-temperature properties (hot ductility and stress rupture life) were investigated in alloy