AZTERLAN

Knowledge Hub

Aurkitu AZTERLANeko lan-taldeak sortutako teknologiak, materialak eta diseminazio ekintzak.

Zeren bila zabiltza?

Garapenak eta gaitasunak:

Diseminazioa

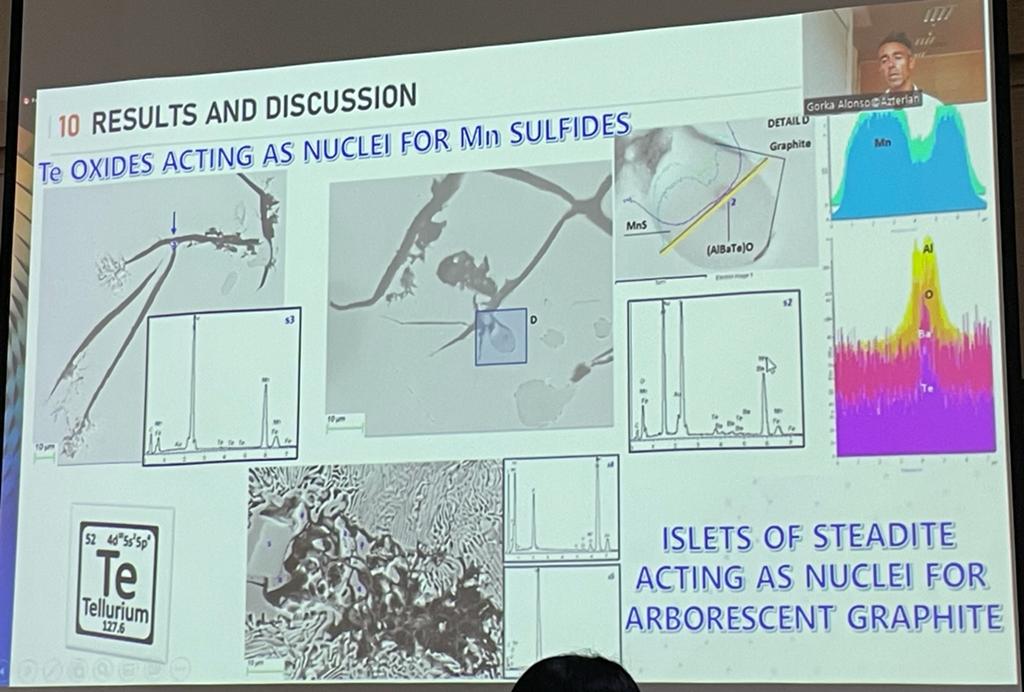

Metastable versus stable solidification of silicon cast irons, effects of magnesium and tellurium

Cast iron is a material with a unique combination of design flexibility, mechanical properties, wear resistance, recyclability, low

Friction Stir Weldability at High Welding Speed of Two Structural High Pressure Die Casting Aluminum Alloys

In this work, the friction stir weldability of two structural high-pressure die casting aluminum alloys designed to manufacture

New Approach to Develop Ductile Cast Iron Digital Grade for Automotive Components

This research work demonstrates that new cast iron materials can be developed aided by an expert digital twin

Density change upon solidification of silicon cast irons

Amongst the possible defects that can appear during casting, voids due to solidification shrinkage is certainly the most

Utilization of steel slag as mold material for green molding castings to minimize silica dust in foundry process

The feasibility of black steel slag as mold material in sand casting, either as full or as partial

Mechanisms of Formation of Degenerated Graphite in Lamellar Graphite Cast Iron

The final morphology of graphite and its effect on the physical and mechanical properties of a cast iron,

Optimization of ductile iron casting production by using advanced thermal analysis and simulation techniques

The use of advanced techniques to control cast iron manufacturing processes lead to important reductions of costs and

New EoL routes of Al Li aircraft integral LBW and FSW welded panels including new Cr free coatings

EoL of new aircraft integral welded panels of 3rd generation of Al-Li alloys welded between them by Laser

The Effects of Holding Time in the Heating/Pouring Unit on the Metallurgical Quality of Spheroidal Graphite Iron

The metallurgical quality of a ductile iron is determined by the components of the metallic charge, as well

Compact graphite iron’s real time manufacturing control by thermal analysis

This research work presents a real time nodularity control methodology by thermal analysis for compact graphite iron (CGI)

A new approach of casting simulation tools integrated in the production line

The use of numerical simulation tools in the foundry is absolutely extended and it has been a strong

Industry 4.0 for aluminum foundry: an optimal management of the process to enhance competitiveness of the company

A standard HPDC industrial manufacturing process is likely to present the following characteristics: Equipment by different manufacturers and

Mechanical properties optimization of as-cast ausferritic ductile iron as a function of section size and holding time

The ADI family shows the best resistance ductility relationship of the ductile iron materials due to an ausferritic

Study of the corrosion behavior of CRA cladded high strength steel for offshore service

Components subjected to corrosion in the Oil & Gas sector are frequently manufactured in Corrosion Resistant Alloys (CRA)

Simulation of hydrogen transport in ultra-high strength martensitic steels with zinc-nickel coating

-No hay información- Autores/as: A. Ravikumar (Helmholtz-Zentrum Hereon), C. Feiler (Helmholtz-Zentrum Hereon), D. Höche (Helmholtz-Zentrum Hereon), M. Zheludkevich

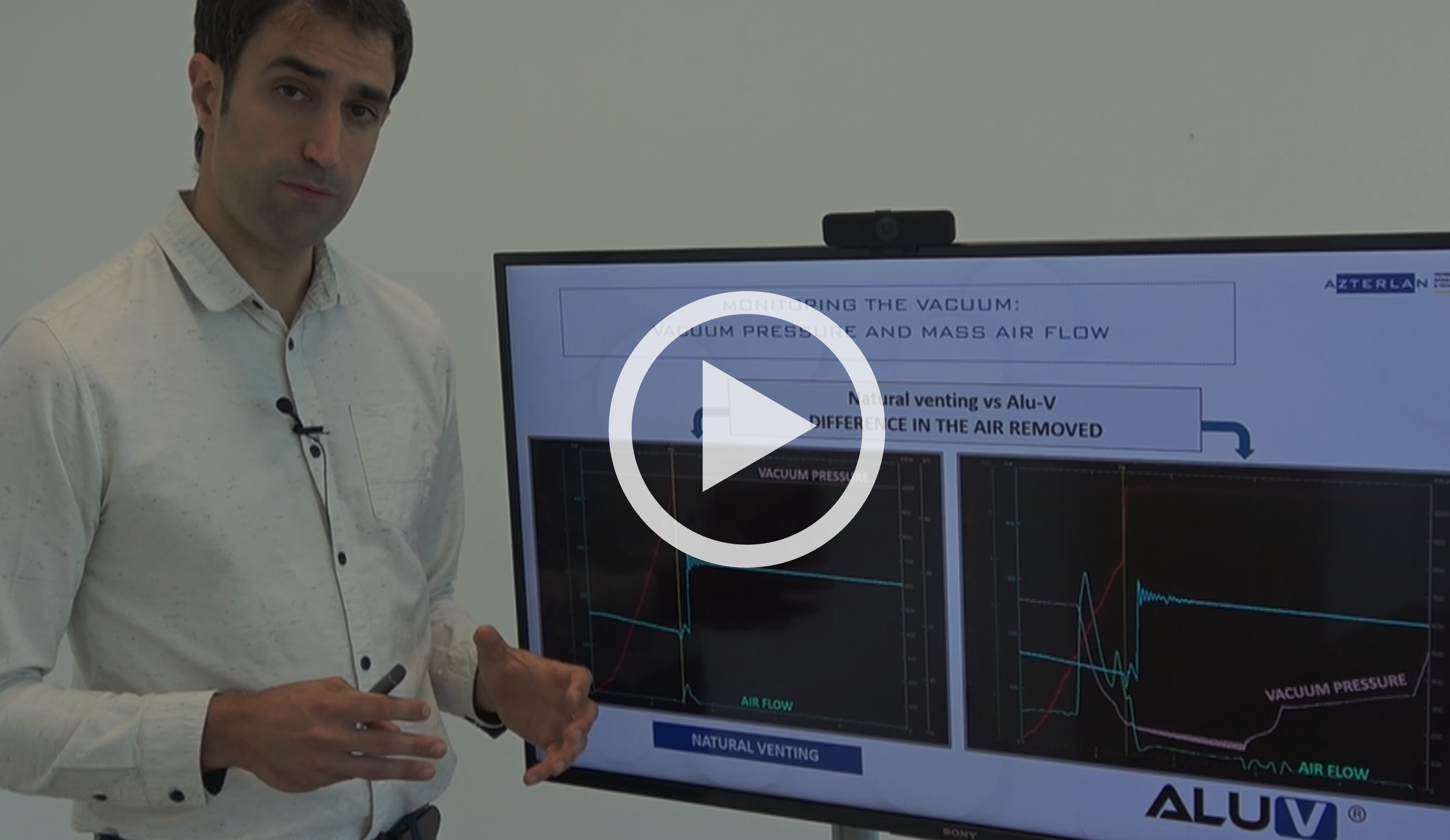

A sound vacuum system fully monitored to ensure the quality of the HPDC components

Gas porosity is an intrinsic feature of the HPDC process due to the fast metal injection that does