AZTERLAN

Knowledge Hub

Aurkitu AZTERLANeko lan-taldeak sortutako teknologiak, materialak eta diseminazio ekintzak.

Zeren bila zabiltza?

Garapenak eta gaitasunak:

Diseminazioa

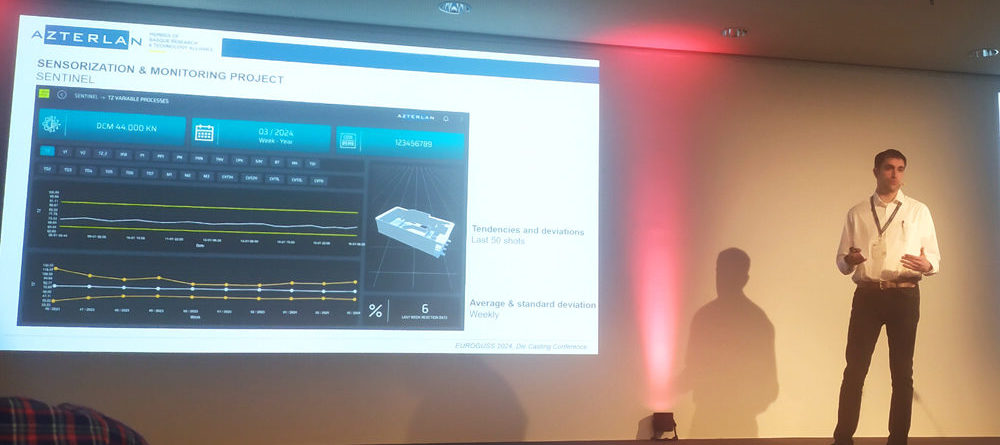

4.0 industria, HPDC prozesua optimizatzeko: nola monitorizatu eta sentsorizatu HPDC injekzio zelda

Zalantzarik gabe, 4.0 industriaren iraultza industria-sektore guztietara iristen ari da, eta HPDC galdategia ezingo litzateke gutxiago izan. Edozein

Rethinking sustainability of metallic alloys

Advanced metallic materials are complex materials with very differents composition. As they are integrated into components, products and

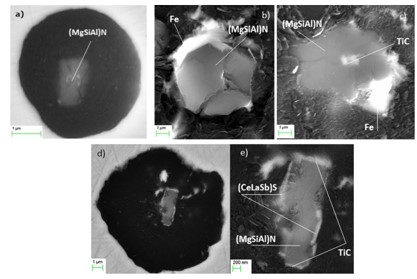

Development of New Hybrid Composites for High-Temperature Applications

Nowadays, in the automation and aircraft industries, there is a challenge in minimizing the weight of components of

Chemical Composition Effects on the Microstructure and Hot Hardness of NiCrSiFeB Self-Fluxing Alloys Manufactured via Gravity Casting

Ni-Cr-Si-Fe-B self-fluxing alloys are commonly used in hardfacing applications; in addition, they are subjected to conditions of wear,

Small Punch Test on Jominy Bars for High-Throughput Characterization of Quenched and Tempered Steel

Studying the effect of quench and tempering heat treatments on steel, more specifically screening the effect of the

Graphite Spheroids – The Way they Grow

Graphite spheroids are one of the most intriguing forms of aggregation of graphite. They can be found as

Graphite Spheroids – The Place where they are born

In the same way that a building needs a solid foundation to remain firm and stable, graphite requires

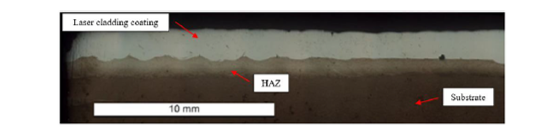

Neurrira egindako L-DED erreminta altzairu baten atomizazio ultrasonikoa eta aplikazioa

The main goal of this work is to manufacture and test a custom L-DED powder for improving wear

Hydrogen permeation testing parameter exploration for high-entropy alloys

Las normas de ensayos de permeación de hidrógeno para materiales metálicos, como ASTM G148 e ISO 17081, se

ZnNi coating on UHSS for aeronautical applications: effect of base material and coating’s microstructure on the degassing process for preventing hydrogen embrittlement

Ultra-high strength steels (UHSS) are currently used in applications where high mechanical loads are required as it is

ZnNi coating on UHSS for aeronautical applications: effect of base material and coating´s microstructure on the degassing process for preventing hydrogen embrittlement

Cast iron is a material with a unique combination of design flexibility, mechanical properties, wear resistance, recyclability, low

A Preliminary Study on the Quality of Joining AISI 316 and AISI 3415 Steel by the Near Solidus Forming Process

In this study, the Near Solidus Forming (NSF) process, which falls under the umbrella of semi-solid processes, was

On the Role of Turbostratic Graphite in the Crystallization of Spheroidal Graphite During the Liquid-to-Solid Transformation

While turbostratic graphite is documented in many forms of graphite, there is a paucity of information on its

Design evolution of Small Punch Test for Cryogenic Conditions

The study of mechanical properties in cryogenic conditions with traditional methods implies a large volume of material to

The mechanism of intermediate temperature embrittlement of cast irons by magnesium

Metallic alloys such as steels and nickel-based alloys are potentially vulnerable to high-temperature brittleness in the range of

High Performance Materials for extreme Energy Intensive Industry Process Environments

Modified cast austenitic alloys have been designed to enhance the creep strength of rollers and beams of a