The technical conference on the optimization of welding processes for offshore applications held at the AZTERLAN Metallurgy Research Centre on the 7th of November brought together practical cases and innovations from the companies NIPPON GASES, VOESTALPINE BÖHLER WELDING, GRI FLANGES IRAETA and NEWTESOL, as well as expert technical knowledge from AZTERLAN’s Failure Diagnosis and Analysis and Physical and Mechanical Properties Testing teams.

Welded joints play a crucial role in structures and equipment that operate offshore, such as oil platforms or wind towers. “The size of these structures continues to grow and they are increasingly required higher performance; this translates into greater mechanical loads and fatigue. At the same time, health and safety requirements keep increasing” as stated by Josean Goñi, head of the Metallurgy area of AZTERLAN. In this scenario, welding processes continue to “evolve and provide new solutions to the sector, accompanying it in its evolution.”

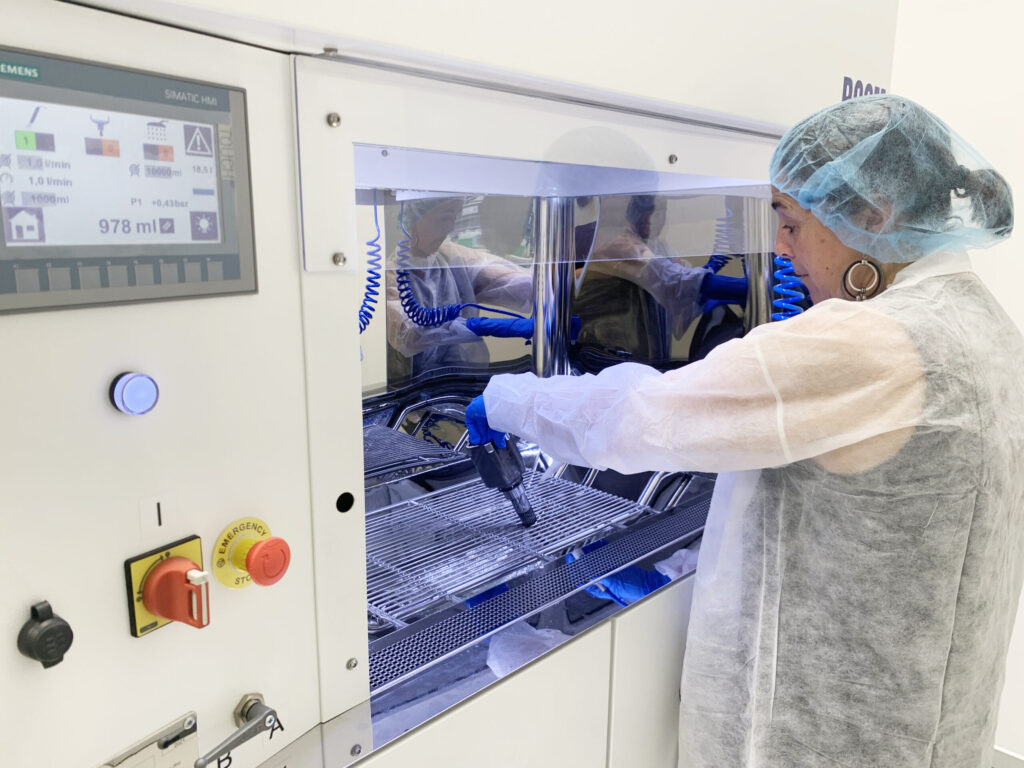

With this idea as a central focus, AZTERLAN held a technical conference on November 7th aimed at sharing “some innovations and developments of interest to the sector.” Through technical presentations by leading companies in different fields, the audience had the opportunity to learn about novelties related to the development of new materials and consumables, new component designs, strategies for streamlining welding processes or the prevention of occupational risks in relation to welding fumes. “The innovations and developments shared by the different experts had as common vectors the great importance of metallurgy and health when designing new products, and the growing relevance of digitalization and process control as a way to obtain better results.”

Among the innovations in the field of consumables and welding processes, Txema Alday, Product Manager of NIPPON GASES, shared some key points related to the evolution of gas mixtures, as well as new developments related to alternative mixtures in the welding of stainless steel offshore components. Alday highlighted the importance of digitalisation and control of the welding process as a “key tool to provide value to our customers”.

Along similar lines, José María Miguel, technical director of VOESTALPINE BÖHLER WELDING, offered an overview of common errors made in heat treatments during welding and shared some guidelines on the selection of appropriate consumables. In a second presentation, and with the focus put on the health of welding personnel, he also presented new developments in welding consumables and components to minimize the emission of welding fumes. “Health and the quality of work environment are fields of growing importance for the sector and the development of consumables must accompany this concern, combining the challenges related to the elimination of elements harmful to health and the metallurgical requirements of the welding process.”

Also representing VOESTALPINE BÖHLER WELDING (Netherlands), Erwin Gering shared with the audience some of his team’s new products and developments aimed at increasing the deposition speed in different types of welded joints. In addition to highlighting the importance of preserving metallurgical properties, the offshore wind sector expert also remarked that the automation of welding processes is one of the keys to advance in this path.

Targeting applications and practical experiences linked to the offshore sector, the session also hosted practical cases from the companies GRI FLANGES IRAETA and NEWTESOL.

Representing GRI FLANGES IRAETA, its quality manager Pedro Verdasco presented a new generation of flanges for the offshore wind sector. In his speech, Verdasco shared some of the technical challenges linked to the development of this innovative product, manufactured by welding, in which “the development of materials and advanced CTOD tests have played a fundamental role”.

For his part, from NEWTESOL, Borja Saiz, CTO of the company, who presented a practical case of repairing Weld Overlay defects in pipes with difficult access, also stressed the importance of advanced tests for the offshore sector, “a sector with high technical demands and which requires special testing and validation processes that are not found in other industries”.

The technical presentations by the AZTERLAN team were aimed at sharing part of the technology center’s knowledge in the field of advanced testing and failure mechanisms that are common in the sector. On the one hand, the head of the Physical Testing area, Urko Uribe, offered a detailed view of the CTOD test, “an advanced test to assessing crack growth that is of great relevance to the offshore sector.” On the other hand, Josean Goñi, head of the Metallurgy and Failure Diagnosis and Analysis areas, shared some key points about hydrogen absorption embrittlement, “a very recurrent failure mechanism in offshore applications.”