REVaMP. Retrofitting equipment for efficient use of variable feedstock in metal making processes

Retrofitting equipment for efficient use of variable feedstock in metal making processes

Project complete

Start date

Horizon 2020

Funded by

869882

grant agreement number

End date

Metals can be recycled over and over again without losing their properties, which is not only good news for the circular economy, but also a big business. The global metal recycling sector, estimated to be worth €250 billion, is growing at an unprecedented rate and the opportunities are limitless.

In order to meet this incessant demand, European metal production factories need to undertake retrofitting works by implementing appropriate sensors for scrap analysis and furnace operation.

The EU-funded REVaMP project has developed, adapted and implemented new retrofitting technologies to address the increasing feedstock variability. The project’s findings have contributed to improving the selection of raw materials in terms of energy and material efficiency.

New technologies to optimize the recovery of metallic materials.

Related contents

Main objectives

The European REVaMP project aims to demonstrate technological solutions to update equipment in the steel production and aluminum and lead recovery industry in order to improve the adaptation of furnaces to metallic loads and alternative fuels of variable composition, contributing to the Energy and resource efficiency in the metallurgical industry.

Within the project AZTERLAN focused in two main working lines:

- Development of a use case for improving energy efficiency together with the companies REFIAL and GHI Hornos Industriales

- Development of Software as a Service to integrate predictive control models and decision tools for monitoring, control and optimized management of steel, aluminum and lead processes in the industrial plants of SIDENOR, GRUPAL ART, REFIAL and EXIDE.

Main results

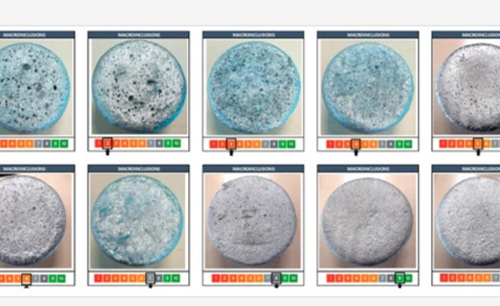

Important steps for a significant progress beyond the state of the art of the metal making industry have been taken in REVaMP project; especially, regarding the successful industrial application of novel sensors (two types of neutron activation and a smart LIBS sensor) for in-line analysis of the metal scrap composition. These sensors provide the basis for a more thorough and reliable analysis of scrap properties, to increase the value in use also of low-quality scrap grades and, hence, to enhance circularity of metal making processes. What’s more, it has been demonstrated in the project that the original Alu-Q® multi-measurement system developed allows a near real-time assessment of key quality parameters of aluminium melts and, thus, enables foundries to reduce the manufacture of defective parts.

The industrial testing of model-based decision support and process control tools for the melting processes of steel, aluminium and lead has constituted another important step forward to the digitalisation of these processes, enabling a more efficient use of energy and resources, which leads to relevant savings.

In spite of promising results at lab scale, the prototype of the innovative aluminium scrap pre-heater built to be powered by a waste derived fuel produced from automotive shredder residue could not run successfully in the project duration. Nevertheless, the trials executed have served to identify redesign solutions and operational adaptions to overcome the problems encountered.

All in all, nine innovative and exploitable results were developed, applied, tested and validated throughout the project. The table below gives an overview on these exploitable results with names of creators and status of exploitation.

-

Scrap mix optimizer for electric steelmaking

(BFI, Sidenor) -

Dynamic monitoring and control of Electric Arc Furnace process

(BFI, Sidenor) -

Smart Visualization tool for lead melting

(Cartif, Exide) -

Charging optimization in lead refining process

(Cartif, Exide) -

Decision suport system for monitoring and optimization of aluminium refining

(Eurecat, Grupal Art) -

Neutron sensor for online elementla analysis of moving small metal scrap pieces

(NCBJ, SYSKON) -

Application of neutron generator and associated particle imaging technique for elemental analysis of steel scrap materials

(NCBJ, SYSKON) -

Laser-based spectroscopic sensor for bulk metal scrap analysis

(Fraunhofer ILT, LSA) -

Alu-Q® equipment for the assessment of liquid aluminium quality

(AZTERLAN)

Impact of the project

The most remarkable environmental and socio-economic impacts of the retrofitting results achieved in the project on the participating metalmaking industries have been:

- Energy efficiency of the involved industrial processes increased by 8.5 % on average thanks to the ensemble of REVaMPed solutions.

- Resource efficiency improved up to 10 %. The improvements in resource efficiency strongly varied with the use cases: the achieved values were in the lower range of 1 % for the steelmaking processes, but reached more than 10 % for aluminium chips recycling and 5% for lead recycling.

- The CO2 emissions were reduced for electric steelmaking by 5.9 %, for aluminium refining by 2% and for lead recycling by 8.7 %.

- Reduced OPEX costs and increased productivity are closely connected with the increased use of low-quality scrap and a reduction of out-of-spec production by a better control of the charge material properties. Achieved saving values range vary from 2.43 €/t for oxygen steelmaking, 6.57 €/t for lead production and 16.76 €/ t for electric steelmaking. For aluminium refining OPEX savings lie around 2%.

- For all use cases, the payback period of the retrofitting solutions is well below five years.

- The assessment of the cross-sectorial transferability of the retrofitting solutions tested in REVaMP indicated that many of them can be transferred to other branches of the process industry with only small adaptations.

News and resources

News

Other activities

Comparative Study of the Metallurgical Quality of Primary and Secondary AlSi10MnMg Aluminium Alloys

Chemical Composition and Melt Treatment Optimization of 5XXX and 6XXX Alloys for Ablation Technology

Alu-Q® – Molten aluminum quality assessment device

Combustion of a Solid Recovered Fuel (SRF) Produced from the Polymeric Fraction of Automotive Shredder Residue (ASR)

Project consortium

REVaMP project is funded by the Horizon 2020 research and innovation programme of the European Union (Grant agreement number 869882).