Dr. Enara Mardaras

“We focus on developing materials and surface treatments that make it possible to manufacture components that will present an enhaced performance in hostile work environments.”

CORROSION AND PROTECTION OF MATERIALS

Materials for the energy of the future

Decarbonization & efficiency Materials for the energy of the future As the need to secure

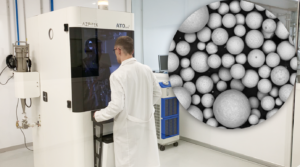

DEVELOPMENT OF METALLIC POWDER – Atomization of metallic powder

New materials Design and development of ad-hoc metallic powders Ultrasonic atomization of metal powders with

In-situ surface modification of high-silicon ductile cast iron produced by sand mold casting

Corrosion is a critical and common problem in cast iron castings used in industry. To

Keys and tools for Hydrogen Embrittlement minimization during ZnNi plating on Ultra High Strength Steels

Ultra-High Strength Steels (UHSS) are highly used in the aeronautic sector in critical components, like

Overlay Dilution Prevention Method in a Single Step L-DED Process

L-DED presents an interesting approach to modify the surface of standard structural steel with stainless

Influence of LP-DED speed (LMD vs EHLA) on corrosion behavior of single layer CRA overlays in marine environments

Corrosion Resistant Alloys (CRA) are high-cost materials but very useful in aggressive environments because of

MONOCOAT – protective cladding in a single layer

Advanced manufacturing MONOCOAT Anti-corrosion and anti-oxidation additive coatings on structural steel in a single clad

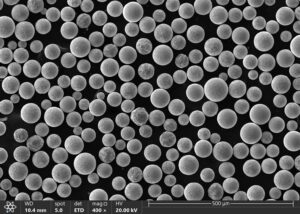

Atomized Ni-Ti powders for reactive paint

NEW MATERIALS Atomized Ni-Ti3 powder Ad-hoc metallic powders for developing protective surfaces. More information Promoting