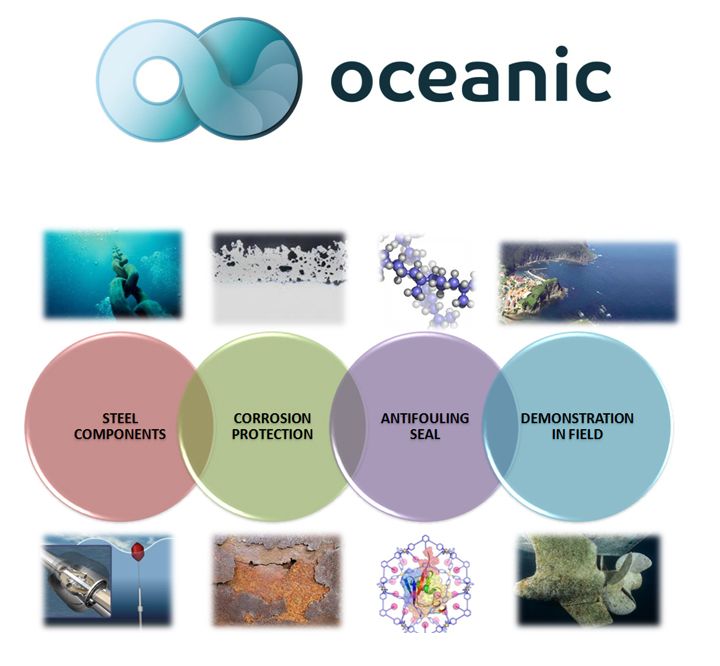

The Research Project OCEANIC is linked to the European Ocean-Eranet program and has a major international consortium of companies, with the active collaboration of IK4 AZTERLAN.

A research effort aimed to provide an advanced solution to the concurrence of three main factors in the performance and service life of the WECs (Wave Energy Converters): corrosion, fouling and proximity to the coast.

Engineered structures operating in or near the marine environment are subject to one of the most aggressive environments for material degradation. Corrosion and fouling phenomena are usually combined, causing accelerated deterioration of the components from any sub-sea installation. Therefore it constitutes a serious problem affecting the durability of any sub-sea installation.

The effectiveness of the traditional anti-fouling solutions relies in the use of biocide containing paints (copper in 80% of the cases) with a high environmental impact, while corrosion solutions are built around the use of the principle “connect to protect”, based on cathodic protection mechanisms.

However, these two strategies are not valid for certain situations, with the occurrence of any of the following factors:

– High-strength steels as base material. The application of printed currents causes embrittlement phenomena, considered unacceptable.

– Moving components. Dragging phenomena reduce significantly the ion transport limiting the corrosion protection.

– Coastal waters. Both by the corresponding environmental responsibility and by the regulations in place, the use of copper is to be restricted.

To meet this challenge, for which there is no up to now an environmentally responsible and economically competitive solution, OCEANIC consortium aims to develop a solution that integrates anticorrosion and antifouling properties in a single component.