DIGITAL TWIN

-

- Follow Us

- —

Ensure the quality of the recovered sand

Based on control software and a minimal network of sensors, this system can be installed in all types of green sand molding functions that wish to stabilize the outlet temperature of their return sand and its overall quality.

This smart system allows:

- Limiting temperature peaks in the return sand

- Ensuring optimal sand moisture before storing it in the silos

- Optimizing the molding sand mixing cycle

- Improving the stability of the casting process

- Ensuring the quality of manufactured parts

Related contents

Digital twin of the return cycle of spend foundry

molding sand

for a real-time control of production

A system tailored to each casting process

- Dosage of water adjusted to the load of the drum, of the sand of the belts and to the characteristics of the production

- Monitoring of the process in real time

Capture and storage of key data

- Signals of the equipment that operates in the process

- Implementation of PDManager® technology for those cases in which the equipment has limited accessibility

- Sensorization of elements and key points of the process not yet monitored

Data architecture and digital twin

- Development of a data architecture

- Monitoring and control of the characteristics of the process, in real time

- Intelligent decision making for the optimal dosing of water in drums and belts at all times. Sensorization plant layout return sand foundry

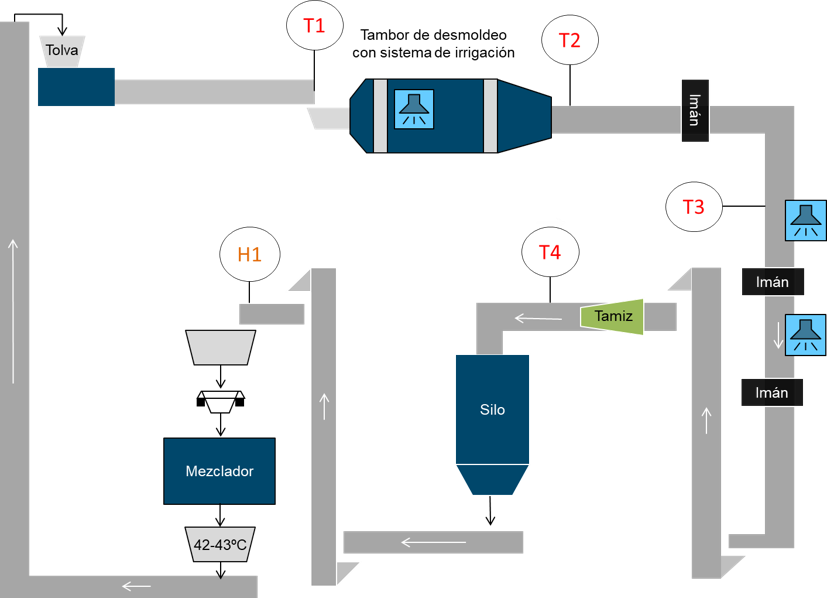

T1

Temperature of castings at the entrance of the drum

T2

Temperature of castings at the exit of the drum

T3

Temperature of parts prior to irrigation

T4

Temperature of sand prior to entering silos

H1

Humindity

Layout example of the implementation of commercial sensors in a demoulding line. Hover over the highlighted items to get details of the captured values.

A minimal network of sensors to capture key data

A virtual twin fed by equipment data and data captured by a minimal network of commercial sensors allow irrigation to be adjusted to the real-time load of the demoulding drum and conveyor belts:

- production cadence

- flow of materials in the process (bypass, vibrating, etc.)

- drum loads

- mold weight and temperature: metal/sand

- sand moisture at different points of the process

- sand temperature at different points of the process

Do you want more information about this solution?

We can help you develop a more efficient function process.

Team

Shaping the

Foundry of the Future

“The Foundry of the Future is that of connected processes that is able to take advantage of the knowledge generated inside the company at the same time that it keeps learning from its manufacturing and market experience.

Along with a deep knowledge of metallurgy, Industry 4.0 technologies, advanced data management systems and machine learning technologies have landed in this industry to transform the way castings are conceived”.

xxxxx