Alu-V®

System to extract gases from injected aluminum molds

Reduce porosity and defects in parts manufactured by HPDC.

- Patented technology

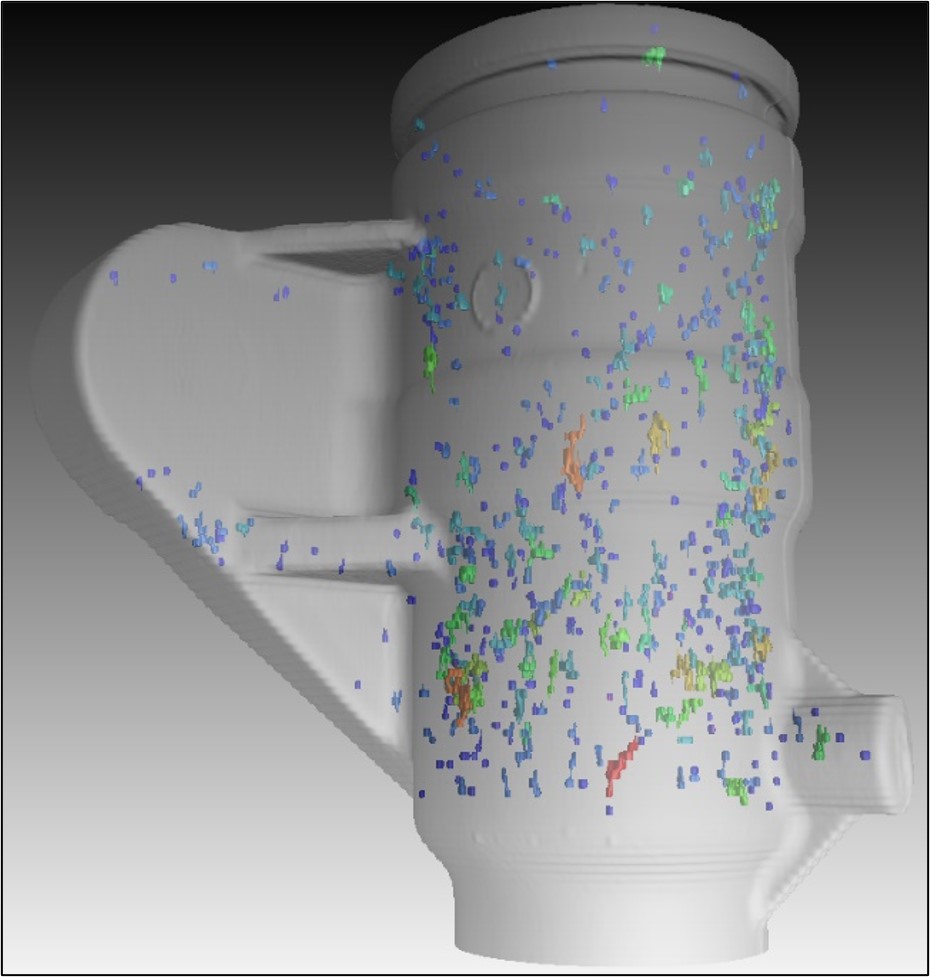

Alu-V® (and Alu-V+ for greater size parts manufacturing) is a forced ventilation system developed by AZTERLAN to generate low-medium vacuum in injected aluminum molds in order to avoid defects in components manufactured using HPDC technology.

It reduces porosity and improves the soundness of manufactured components, favoring, in particular, the creation of parts with thin walls, the development of structural components and ensuring the weldability of injected parts.

Sequential vacum

Vacuum level (mbar)

Dimensions (mm)

DCM (t)

Pollution test

HPDC for structural components (High vacuum)

Portability

Basic monitorization

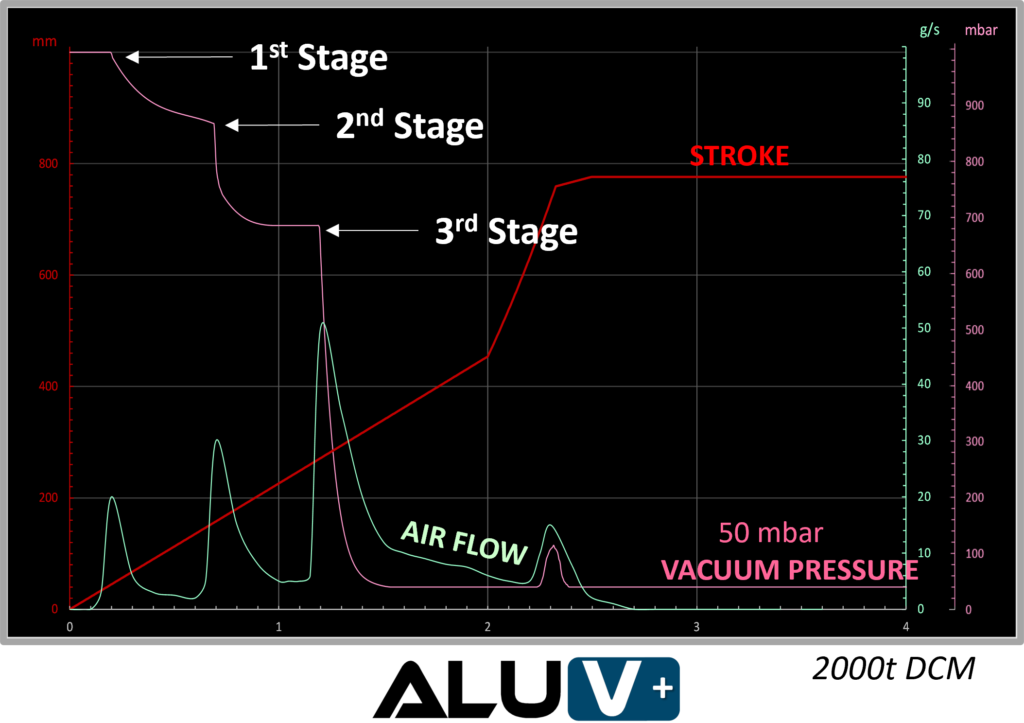

Full monitorization: Air flow vacuum pressure synchnonized with the die casting curves

2 stages

<100

1200x1250x650

<1200

yes

–

yes

Optional

yes

3 stages

<10

1200x1775x2057

1000-3200

yes

yes

yes

Optional

yes

The Alu-V® and Alu-V+® systems offer all the vacuum pressure monitoring data synchronized with the casting curves.

This is highly relevant information that can help detect pressure leaks in the molds and, with this, prevent manufacturing defects due to poor mold closure.

“The Foundry of the Future is that of connected processes that is able to take advantage of the knowledge generated inside the company at the same time that it keeps learning from its manufacturing and market experience.

Along with a deep knowledge of metallurgy, Industry 4.0 technologies, advanced data management systems and machine learning technologies have landed in this industry to transform the way castings are conceived”.

xxxxx

How can we help you?

Mantente informad@ de la actividad de AZTERLAN.

Keep up with AZTERLAN’s activity.

Keep up with AZTERLAN’s activity.

We train workforce in different fields regarding the production of metallic alloys, components and structures.

We will contact you as soon as possible.

Share your challenge with us.