Advanced High Strength Steels (AHSS) are designed to provide an efficient answer to the actual demands from the automotive industry, with more and more strict safety regulations, constant weight reduction demands, CO2 emission restrictions and good forming properties, all of them within a reasonable cost. They are complex and sophisticated materials with a carefully selected chemical composition and multiphase structures as a result of precise and controlled heating and cooling processes. The hardening mechanisms involved for reaching the range of properties such as strength, ductility, fracture toughness and fatigue are extraordinarily diverse.

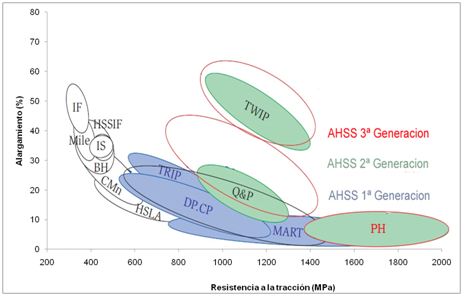

Dual phase steels (DP), with a ferritic-martensitic structure, Tranformation-Induced Plasticity steels (TRIP) and the Martensitic Steels (MS), belong to the second phase from the 1st Generation of AHSS steels. Twinning Induced Plasticity steels have been developed more recently and they are part of the 2nd Generation of AHSS. They are materials with a more complex chemistry, with high manganese and high silicon, along with exceptional mechanical properties that are above the TRIP steels (Figure 1).

Figure 1. Tensile strength versus strain for different stamping steels.

TWIP steels have an austenitic structure at room temperature and therefore they require a high manganese content (17-30%) within their chemical composition. This implies certain specific challenges in the melting and secondary metallurgy processes.

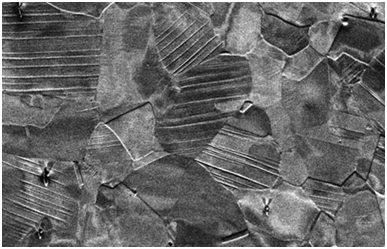

During the forming operations of these materials the microstructure suffers a change in the crystalline orientation inside the grain, which is known as twinning (Figure 2).

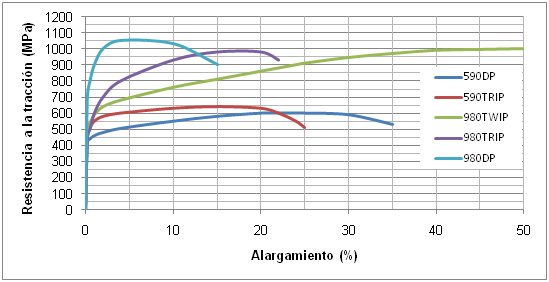

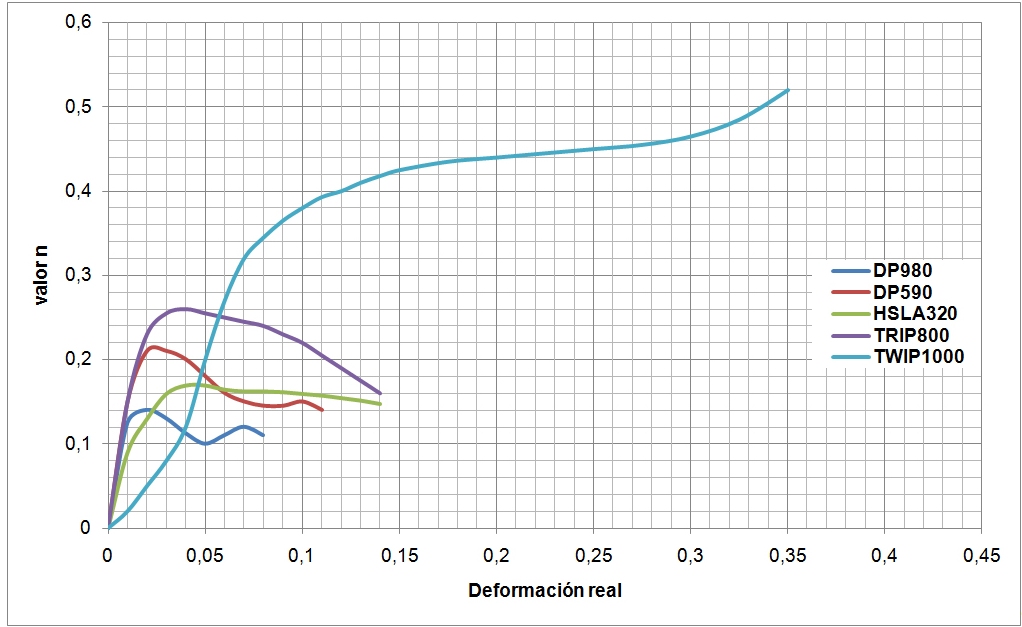

Essentially, twin boundaries must be considered true grain boundaries and the final result is a steel with extraordinary forming properties and very high strength values (Figure 3) along with a significant increase of the strain hardening exponent (n value) (Figure 4).

Figure 2. Twins in austenitic grains of a TWIP steel.

Figure 2. Twins in austenitic grains of a TWIP steel.

Figure 3. Stress-strain curves of different AHSS.

Figure 3. Stress-strain curves of different AHSS.

Figure 4. Work hardening versus true strain of different AHSS

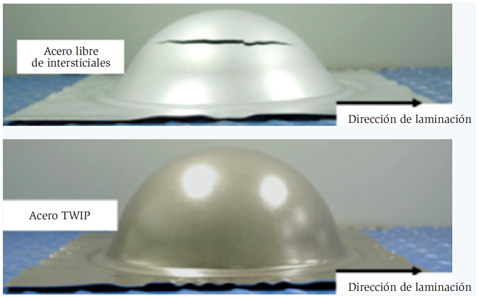

According to the information provided by these steel manufacturers it is possible to reach up to 35% deformation with a tensile strength of 1400 MPa, as well as an exceptional capacity to absorb impact energy. An example of its deformation limits can be observed in the Nakajima forming test that compares this material with an Interstitial Free steel (IF) (Figure 5).

Figure 5. Nakajima forming test.

Figure 5. Nakajima forming test.

On the other hand TWIP steels have a low yield strength in annealed conditions (@250 MPa) and the high strength values are only reached after a remarkable deformation of the material. An open working line to overcome this challenge is the cold rolling of the material and/or some micro-alloying elements to achieve precipitation hardening. In this regard, vanadium, niobium and titanium are elements which are being analyzed.

One aspect to consider in the TWIP steels is related to the precipitation of cementite in the grain boundaries during annealing, that might result in a steel with hydrogen embrittlement and delayed cracking. In this particular case, recent developments propose the addition of aluminum between 1.5% and 2%, that avoids the precipitation of cementite during cooling after the hot rolling and annealing, due to a decrease of the reactivity and the diffusivity of the carbon in the austenite.

These advanced and innovative materials have a set of properties such as high strength, excellent ductility values, good impact resistance capabilities, along with a reasonable cost that makes them very interesting, enabling more energy-efficient designs and allowing considerable weight reductions with the corresponding compliance of the safety requirements.

One of the main challenges in the use of these materials relies in the metallurgical knowledge of the relationship between their mechanical properties and micro-structural characteristics. Without any doubt this understanding will push the introduction of TWIP steels in the automotive industry and in other sectors such as railway, shipbuilding, piping and any other additional specific applications that do not require magnetic materials.