Dr. Susana Méndez

“Foundry is named to keep a leading place among the manufacturing technologies of the future. R&D, along with new process control and monitoring technologies, is a key tool to ensure that possition.”

Foundry Technologies

METALLURGICAL COMPENSATOR – Promoting graphitization in the last stages of solidification

New manufacturing technologies METALLURGICAL COMPESATIVE PRODUCT Promotes late graphitization to ensure the quality of ductile

ALU-V® – Vacuum generation system for HPDC manufacturing

Intelligent manufacturing Alu-V® System to extract gases from injected aluminum molds Reduce porosity and defects

An innovative secondary aluminium AlSi10MnMg(Fe) for structural components with high ductility requirements

AlSi10MnMg primary aluminum alloy is widely used to manufacture structural components in the automotive market,

Industry 4.0 to optimize the HPDC process: how to monitorize and sensorize the HPDC cell

Undeniably, industry 4.0 revolution is reaching every industrial sector and the HPDC foundry could no

Rethinking sustainability of metallic alloys

Advanced metallic materials are complex materials with very different compositions. As they are integrated into

Development of New Hybrid Composites for High-Temperature Applications

Nowadays, in the automation and aircraft industries, there is a challenge in minimizing the weight

TREAT- Optimization of Heat Treatments (methodology)

Sustainable manufacturing processes TREAT Efficient Heat Treatments Methodology for the development of optimized thermal treatments

Chemical Composition Effects on the Microstructure and Hot Hardness of NiCrSiFeB Self-Fluxing Alloys Manufactured via Gravity Casting

Ni-Cr-Si-Fe-B self-fluxing alloys are commonly used in hardfacing applications; in addition, they are subjected to

Small Punch Test on Jominy Bars for High-Throughput Characterization of Quenched and Tempered Steel

Studying the effect of quench and tempering heat treatments on steel, more specifically screening the

Graphite Spheroids – The Way they Grow

Graphite spheroids are one of the most intriguing forms of aggregation of graphite. They can

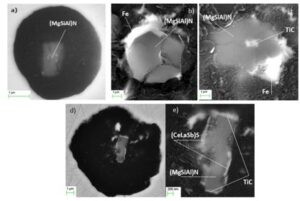

Graphite Spheroids – The Place where they are born

In the same way that a building needs a solid foundation to remain firm and

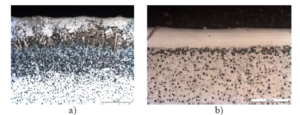

Metallic Powder Manufacture for Conditioning Cast Iron as an Additive Manufacturing Substrate

The main purpose of this work is to design and develop a metallic powder to