Dr. Susana Méndez

“Foundry is named to keep a leading place among the manufacturing technologies of the future. R&D, along with new process control and monitoring technologies, is a key tool to ensure that possition.”

Foundry Technologies

Comparative study of emissions from molds manufactured with inorganic binders, organic binders and by green molding

With the aim to compare the emissions from the inorganic binder system (sodium-silicate based) with

Diagnosis – BREF for the Smitheries and Foundries Industry

Sustainability and environment Smitheries and Foundry Industry BREF Diagnosis Do you know the positioning of

Main novelties of Smitheries and Foundry Industry BREF document

When the new BREF for Smitheries and Foundry Industry has been published, foundry companies have

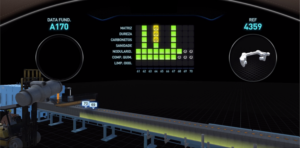

Mold by mold control

In the iron casting process, especially in the case of green sand moulds, the significant

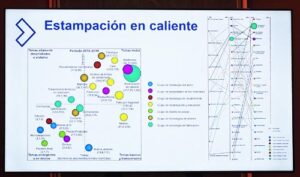

Decision-making predictive model development for the organization active positioning faced with the appearance of new technologies

We are now living in a world where the globalisation phenomenon has changed the world

Classifying and Characterizing Fast Nodular Iron Casting Metallographies by Applying a Similarity Search Method

Currently, society is experiencing a new Artificial Intelligence revolution with the creation of Large Language

KASANDRA® – Software for a real-time prediction of the risk of defect apparition

Iron Foundry KASANDRA® Real time predictive simulation for spheroidal graphite iron foundry High yield designs

SMART DOSING SYSTEM – Mg treatment manager

High yield foundry solutions SDS – SMART DOSING SYSTEM Intelligent Mg dosing manager for cored

Foundry Recipes Optimizer

Iron Foundry Foundry Recipes Optimizer Design the perfect melt. Assured metallurgical quality Add recycled materials

Materials for the energy of the future

Decarbonization & efficiency Materials for the energy of the future As the need to secure

Supporting foundry workers with an AI-based multimodal system tunned using foundry knowledge

Currently, society is experiencing a new Artificial Intelligence revolution with the creation of Large Language

The couple of advanced Thermal Analysis and casting simulation to predict the component’s soundness directly on the pouring line and before the shake out. The Kasandra® method

The use of powerful computers has led to develop complex simulation solidification software’s based on