AZTERLAN Metallurgicy Research Center works on advanced methods for recovering and recycling metallic materials present in the fuselage assemblies of aircrafts, in order to develop and apply welding processes that facilitate their reuse for these same aeronautical applications. This research work is being carried out within the ReINTEGRA European project.

ReINTERGRA consortium is studying different ways for recovering welded aeronautical alloys, to be reused in the same applications with minimal or no adjustments during the recycling process. Specifically, the research team focuses its efforts on the development of the dismantling and recycling processes of aircraft panels manufactured in third-generation Al-Li alloys welded by means of LBW (Laser Beam Welding) and FSW (Friction Stir Welding) techniques to stringers, manufactured in aluminium alloys, which make up the outer skeleton of aircraft.

As explained by Dr. Ana Isabel Fernández, coordinator of the ReINTEGRA project, “each joining process affects differently to the recyclability of the materials/components joined. In the case of the FSW welding technique, welding is carried out in a solid state, with the help of a sealant and with a heat transfer that is lower than that of other types of welding processes, but it covers a larger surface area of the materials joined together. In the case of the LBW technique, welding is carried out by providing one or more welding cords that melt at a very high temperature, thus meking it possible the two metal components be welded to each other”.

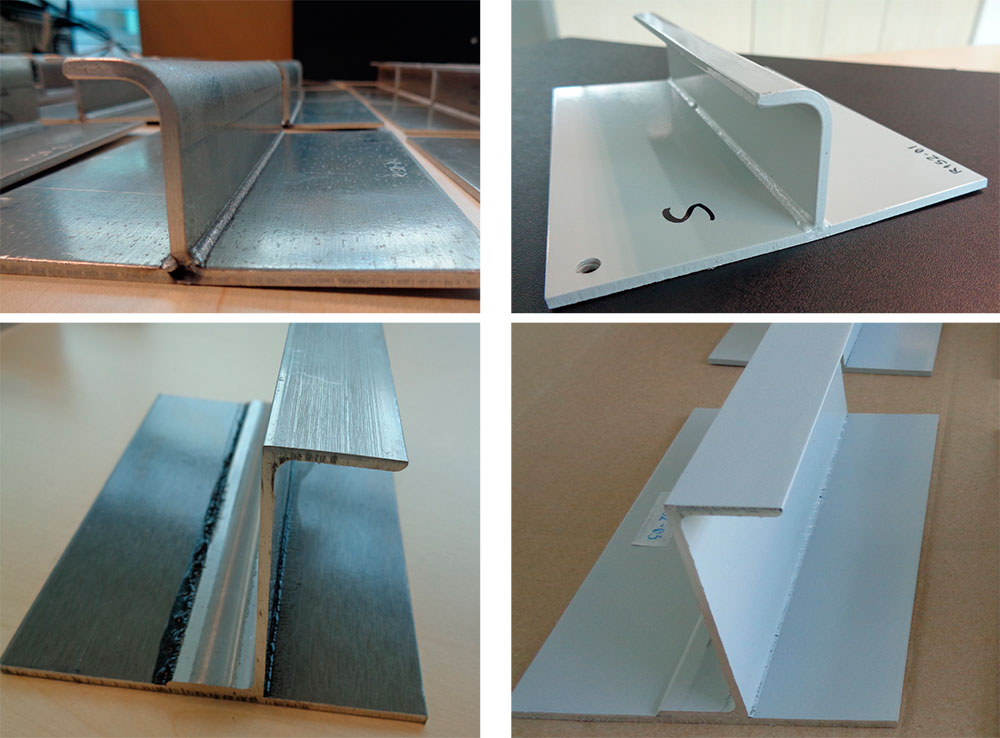

Samples of parts welded by means of LBW without coating (top left) and painted (top right); and samples of FSW welded with no coating (below left) and painted (ibelow right)

With the aim of studying the incidence and possible incompatibilities between the manufacturing materials of the panels and stringers, the welding techniques and the elements used for welding (sealant and the wire), the ReINTEGRA team has analyzed different samples of welds obtained from various types of material combinations and processing techniques.

In the case of weldings made by LBW the team has studied the effect of the application of 4 different wires (2 widely used commercial wires and another 2 threads expressly developed in the Clean Sky2 IAWAS project for this purpose). The results of the analyses carried out have made it clear that the chemical composition of the weld cords directly affects their recycling compatibility. “We have been able to observe that the high silicon content present in one of the wires used affects negatively to the recoverability of recycled materials, making it difficult to reuse them in high-quality alloys”. However, in the tests carried out to the welds made using FSW technology have demonstrated “a total compatibility for recycling”. In this case, the research team has found out that “commercial Al-Li alloys can be obtained to which only small additions of some alloying elements such as Li, Mg or Ag” would have to be made.

In the words of Dr. Fernández, “it is important to keep in mind that, when we talk about compatibility for recycling, the objective of ReINTEGRA is not only to recover and reuse the base materials of the panels and stringers, but to recover them so that there is no downgrading in the starting alloy. Within ReINTEGRA we seek to achieve the chemical compositions to be as close as possible to the original ones, without generating impurities in the aluminum or losing valuable alloying elements”.

To achieve this goal, the research team is also studying different recovery methods that allow maximizing the recovery of metal alloys with the aforementioned characteristics. In this sense, “we have found that some recovery methods offer a high degree of success but that, although are valid at laboratory scale and as a demonstration they, they cannot be extrapolated to an industrial environment because they are excessively complex and not very viable”. Similarly, other methods have proven “to be valid to obtain new aluminum alloys, but they involve the degradation or loss of other valuable alloying elements during processing.”

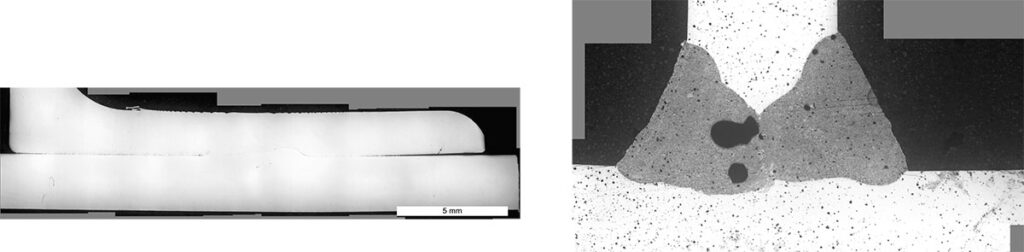

Micrography of parts welded by FSW (left) and LMW (right).

However, the work within the project is aimed at achieving the greatest efficiency of the process in terms of costs, environmental impact and effectiveness in the recovery of metals, to finally select the best recycling alternatives for welded panels.

“We must not forget that, in this process of recovery and recycling, pickling processes also have an important weight, aimed at eliminating layers of paint and surface treatments applied on the fuselage of aircrafts (either for aesthetic purposes and / or as a protection against corrosion)”.

Development of a software to evaluate the compatibility of welding materials with the recyclability of metallic materials and a Life Cycle Analysis of the aeronautical sector

The results obtained by the ReINTEGRA team show the “importance of contemplating the compatibility of the welding process and the materials used (as well as the surface treatments to which they are subjected) tihinking on their recyclability, from the design phase of components, structures and processes, such manufacturing or assembly” since only in this way can their recovery be ensured without losing their added value. In the current scenario, in which the aeronautical industry ains at being to be more sustainable, “we cannot allow a recycling problem to be generated from design”.

To this end, the research team of the project is developing a software that will analyze the recycling compatibility of any structure welded by FSW and LBW that combines Al-Li alloys for reuse in aeronautical alloys, based on the estimated chemical composition of such combination. This modelling software will be fed with the experimental data of the recycling tests and their subsequent characterization.

Along with this, the energy and material flows (raw materials, emissions, and waste) will be inventoried during the experimental phase to estimate the environmental impacts of the proposed recycling processes and will become part of the Life Cycle Analysis database of the aeronautical sector under construction.

Led by AZTERLAN, the ReINTEGRA project has the participation of the Belgian company SONACA (Societé Nationale de Construction Aerospatiale SA) and the CIDETEC technology center, together with two leading industrial advisors such as the French company CONSTELLIUM and the Spanish company AIR. This project has received funding from the Clean Sky 2 Joint Undertaking (JU) under grant agreement No 886609.