Hand in hand with the test equipment manufacturer ZwickRoell EMCO-TEST, some thirty professionals from companies from various sectors related to metal-mechanical transformation have deepened their knowledge of hardness properties and different testing techniques, together with the recent update of the standard for determining the thickness of surface hardened layers of steel ISO 18203:2022.

Hardness tests are a widely used tool to evaluate the mechanical properties of metallic materials, as well as to determine if the thermal and thermochemical treatments carried out on the components have been carried out adequately. The load applied to the indenter, the duration of the load, the quantity and the distance between the hardnesses to be carried out on the sample and the geometry of the indenter are the fundamental criteria on which the final evaluation of the test is carried out.

The international standards for the evaluation of depth of hardness strengthen the framework of acceptable compliance ranges and the procedures to follow for the correct performance of these tests. In order to find out about the most recent updates on the depth of hardness standards for steels and deepen the knowledge about the characteristics of the hardness properties and the different test methods, AZTERLAN and ZwickRoell EMCO-Test have held a technical conference dedicated to this field of knowledge.

As an introduction to the central theme of the day, the first intervention of the session was given by Iva Konstantinova, who detailed the main characteristics of the Rockwell test methods (ASTM E18 and ISO 6508-1), Vickers ( ASTM E92 – Macro and ISO 6507-1), Brinell (ISO 6506-1 and ASTM E10) and Knoop (ISO 4545-1), these being the most conventional and most used. The ZwickRoell EMCO-Test expert has detailed the main criteria for selecting the most appropriate method, “depending on the material to be tested, its homogeneity and its hardness; as well as the size and geometry of the piece or sample to be tested, the number of test points required or the level of precision required”, among others. Subsequently, in a second part of her intervention, Iva has also made known technical aspects of less conventional hardness tests, making efficient in the nano-indentation method (ISO 14577-1) and Jominy tests (ISO 642 ).

Focusing his presentation on updating the standards relating to hardness testing and, specifically, on the determination of the thickness of the surface hardened layers of heat-treated steels, ZwickRoell EMCO-Test engineer Iñaki Gutiérrez summarized the main ISO innovations 18203:2022, “which comes to unify and simplify aspects collected by its predecessors (ISO 2639, DIN 50190-3, DIN EN 10328 and ISO 13208)”. Among the novelties are the contribution of new definitions regarding aspects such as the cementation depth (CHD), the surface hardening depth (SHD), the nitriding hardening depth (NHD), the total surface hardening thickness (THD) and the thickness of the composite layer (CLT); as well as procedural and equipment-related changes.

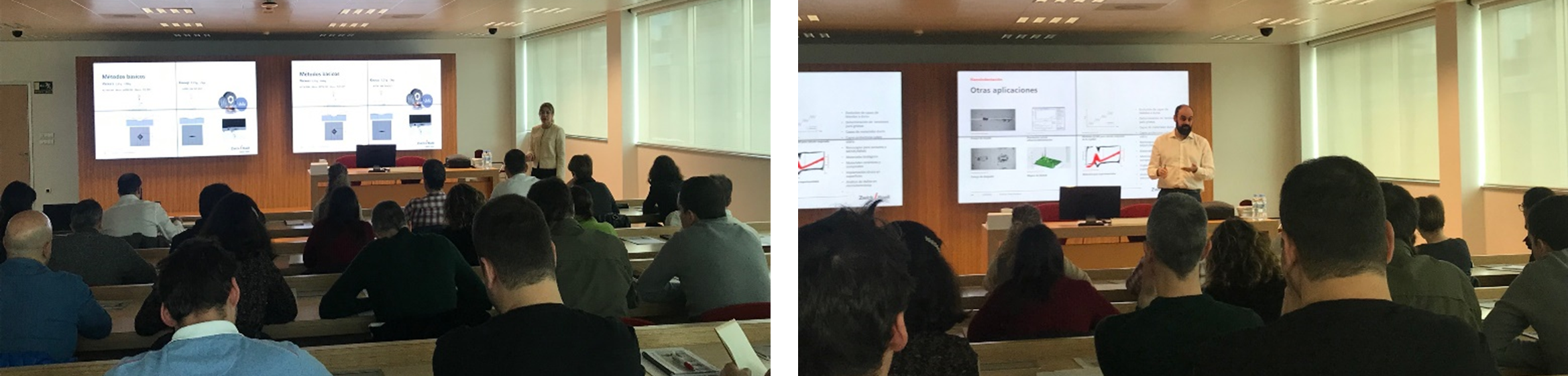

Iva Konstantinova and Iñaki Gutiérrez, from ZwickRoell EMCO-Test, during their technical presentations

The session ended with a visit to the facilities of the AZTERLAN Technology Center, which has among its capabilities equipment for carrying out all kinds of hardness tests (Vickers durometers and microdurometers, Brinell durometers and Rockwell durometers), and which is accredited by ENAC, according to certificate no. 59/LE069, for carrying out different types of hardness tests.