Ik4-Azterlan has participated in the development of this European Project recently awarded, which has allowed to recycle efficiently fuselage elements, for current planes and also for upcoming aircrafts which will include advanced aluminum-lithium alloys with improved coatings.

The aeronautical industry faces the challenge of manufacturing new lighter planes in order to reduce consumption and emission levels. Aluminum-lithium alloys are excellent candidates to achieve the fuselage weight reduction, mainly because lithium is the lightest metallic compound on earth. Nevertheless, it has to be taken into account that lithium costs 30 times more than aluminum and that most of these alloys include as well another expensive elements, such as silver.

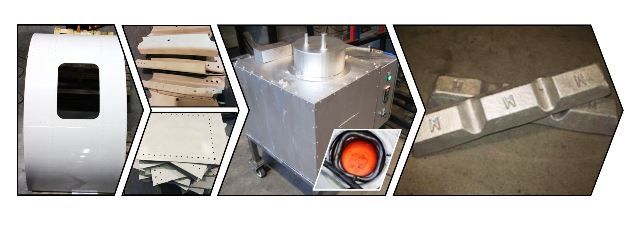

IK4-Azterlan research work during the Project (18 months) has focused on the design, development and validation of a de-coating and recycling methodologies for every aluminum alloy used in three different fuselage panels previously selected.

The developed methodology has proven that the re-using potential is maximum. The lack of contamination and the high quality ingots obtained after the recycling process will allow manufacturing the same aeronautic components using this recycled raw materials again.

The melts performed in IK4-Azterlan facilities have allowed to recover the 7 pre-selected aluminum alloys, obtaining high recovery yields for the metallic content of aluminum and other critical elements, such as lithium and silver.

The developed recycling methodology is able to maintain the initial value of these elements, avoiding the economic loss that occurs when using current recycling processes.

The SENTRY Project has been awarded with the best project prize during the celebration of “Best CleanSky Project Awards 2016”, which took place in Brussels on the 4th of April. This ceremony gathered members and partners from Clean Sky, as well as aeronautical sector enterprises and representatives of the European Parliament and European Commission.