This ambitious R&D project is part of the Clean Sky 2 initiative within the H2020 framework program and has as main target to improve the mechanical properties and the service life of short and medium range aircraft engine turbines. The project will be carried out in collaboration with the company Alfa Precision Casting and IK4-Lortek.

European aerospace sector faces important challenges in order to maintain its competitiveness level at a global scale. Developing more efficient and cleaner technologies and extending the life of its components are some of the objectives currently pursued by this sector. In this direction, the Clean Sky Initiative (already in its second edition) was created as the largest research program coordinated by the European Commission and the European aeronautics industry to develop and integrate state-of-the-art technologies in order to optimize the environmental and economic impact within Horizon 2020 workframe.

Fully aligned with these challenges, the HiperTURB project coordinated by the IK4-AZTERLAN Metallurgical Research Center has as its main target to develop high efficiency engines (UHPE) for short and medium range aircrafts, by optimizing some of their key components.

Improving engine efficiency through its components

Among the aeronautical components, the turbine rear frame (TRF) deserves special mention as it represents about 16.3% of the weight of the aircraft’s engine and 15% of its total cost. As a component it has a limited service life. For security reasons it gets usually replaced at 30% of its expected life.

Currently, the manufacturing of TRFs is mostly made from high performance alloys (super alloys) which offer excellent mechanical strength, high temperature resistance, stability and high resistance to corrosion and oxidation. More specifically, the alloy used for this purpose is a nickel base alloy named IN718.

The machining operations of these kind of alloys is quite complex. This factor, along with the dimensional and geometrical complexity of the components, determines that the most suitable technology is to be manufactured by the lost-wax casting process (a wax model is used to create a ceramic mold so the alloy is cast in this cavity). Partial sectors of the component have to be manufactured first and then welded to configure the TRF.

Given these limitations, the work-team of the HyperTURB project has settled the following targets:

- To improve the weldability of the alloy and its associated mechanical properties to reduce the component’s final weight and thus contribute to reducing CO2 (by 30-20%, in line with the Clean Sky 2 project target) and Nitrogen Oxide (NOx) emissions.

- To increase component service life and reduce vibration and noise emission (-11EPNdB per operation, aligned with Clean Sky 2 target), increasing the comfort levels and reducing maintenance costs.

- To reduce rejection and recovery ratios during the manufacturing process in order to make the part more economically profitable.

These are some of the activities to be carried out by the project:

- Optimization of the manufacturing process of some engine components (by integrating technologies related to the adjustment of the composition, nucleation and cooling control) that will allow to modify castings’ microstructure and the resulting tensions.

- Integration of new thermal treatments (cryogenic treatments) and / or modification of the existing ones, supported in advanced thermokinetic models, in order to guarantee greater weldability and durability of the alloy.

- Development and validation of new welding controls, repair and execution techniques, ensuring that welded joints fulfill mechanical characteristics and have no defects.

Along a 3 year working plan, the project aims to develop new technologies and expert knowledge to allow the participant companies to approach the market with guarantees of success when it comes to product marketing and providing technical support to industrial customers.

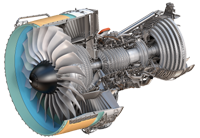

Turbine infography