On April 24th, Corrosion Awareness Day is celebrated, an international awareness day that aims to make visible the effects of corrosion on economy, health and the environment. As a Technology Center specialized in metallurgy, AZTERLAN dedicates significant efforts to fight against corrosion, a phenomenon that strongly affects the integrity and service life of metal components.

Corrosion is the most frequent cause of deterioration and failure of metal components and structures. Its appearance is a consequence of the electrochemical reaction between the surface of the metal and the environment to which it is exposed. It is a phenomenon that affects all industrial sectors transversally, as well as other areas of society less linked to industry.

Although corrosion is a natural and unavoidable phenomenon, it is possible to delay its appearance by acting on all phases of component development, from design to manufacturing. To this end, knowledge of the characteristics of the different metallic alloys, analysis of the service conditions of the components and compliance with the regulatory requirements of the corresponding application sectors are key factors to mitigate and minimize their effects.

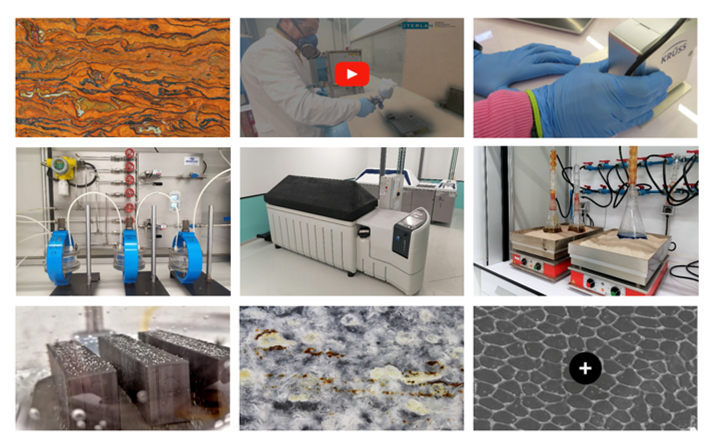

With this objective, the AZTERLAN Metallurgical Research Center has important capacities aimed at accompanying the metal-mechanic industry to prevent and fight against the corrosion of its products.

In the field of R&D, AZTERLAN focuses its research efforts on the development of multi-material componentes with protective surfaces for specific uses in service. The development of multi-material components makes it possible to separate the structural function and the function of resistance against corrosion, incorporating protection properties through protective surfaces based on CRA adapted to each medium.

On the one hand, AZTERLAN Technological Services has the ENAC certification according to ISO 17025 for corrosion tests. Its offer includes a wide range of environmental tests, tests in acid media and hydrogen embrittlement tests carried out under UNE, ISO and ASTM international standards and according to customer specifications.

Finally, AZTERLAN complements its offer in this field with the study of component failures in service due to corrosion pathologies. These are studies of high added value that can provide highly relevant information to designers, product managers and engineering companies, to detect possible deficiencies and weaknesses in their designs or processes, in order to prevent future incidents.

Likewise, the AZTERLAN Knowledge Hub repository gathers knowledge and resources developed by the AZTERLAN team to improve the understanding of the behavior of materials to corrosion and the center’s technological developments to mitigate and delay corrosion.