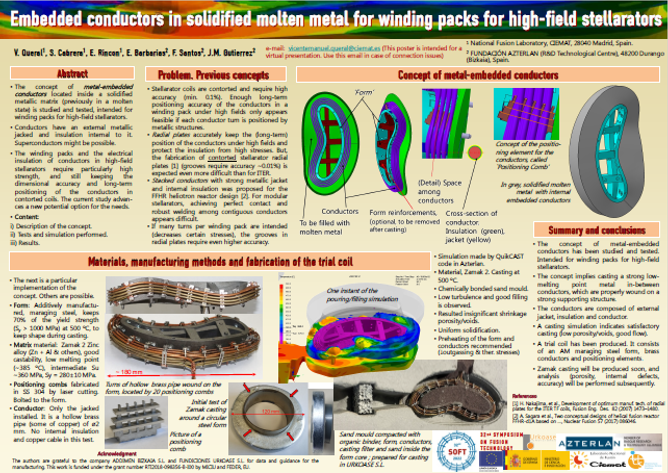

The AZTERLAN Metallurgy Research Centre collaborates in this significant development, both in the selection of materials, and in the design of the feeding and filling systems to embed the coil of a “stellarator” by means of casting technologies, simplifying manufacturing process and facilitating the electrical insulation of the set.

Stellarators are key elements in the generation of nuclear fusion energy. Theri function is to control fusion reactions through the confinement of hot plasmas, using strong magnetic fields. The metal components that are part of the stellarators are therefore subjected to demanding working conditions.

This is the case of the winding packs and the electrical insulation of the conductors of nuclear reactors. These coils are curved elements that require of a high dimensional precision, which must also be kept operational in the long term.

Until now, this dimensional precision only seemed possible if each turn of the conductor was positioned by metal structures. As explained by Vicente M. Queral, researcher at CIEMAT (Center for Energy, Environmental and Technological Research), “the approaches that have been made so far for this implementation have been based on the development of overlapping metal plates that form the winding pack. However, for stellarator-type reactors it is expected that plates with more complex designs will need to be developed and, consequently, it will be more difficult to achieve the level of accuracy required (a deviation of less than 0.01% for certain elements of the plates). In addition, this need for precision is higher if it is intended to increase the number of turns to be given by each of the winding packs… For this reason, we believe that it is necessary to explore new ways that will allow the integration of these elements”.

To this end, the team has proposed an innovative concept of conductors embedded in metal, based on the combination of a casting matrix and the use of additive technologies. This new approach has had the participation of the AZTERLAN Metallurgiy Research Centre, which has collaborated in the selection of the most suitable materials to coat the winding and stiffen the assembly, as well as in the design of the filling and feeding system of the mold to manufacture the set.

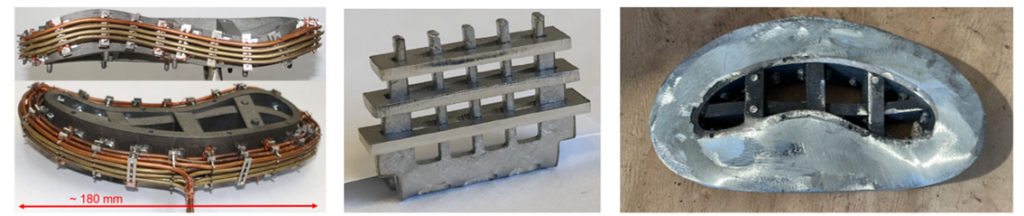

As explained by Fernando Santos, AZTERLAN Special Materials and Processes researcher, “in this new approach, on the one hand, we have the conductors, formed by a brass jacket, interior electrical insulation and electrical conductor. On the other hand, we have a metal of high hardness and low melting point, specifically a Zamak alloy, which we will use to manufacture the matrix and, finally, we also have a strong structure (built in martensitic steel by means of laser technology), on which the conductors will be fixed. prior to pouring the liquid metal into the mold. From AZTERLAN we have defined the manufacturing and control process of this phase of the development of the element, including the design of the feeding and filling systems of the mold”. In the words of Fernando, “in this process, ensuring a correct feeding of the metal and a low porosity of the matrix are key aspects. The preliminary simulations we have carried out show that the structure of martensitic steel applied by LMD maintains its shape at 500ºC, being able to resist the temperature of the liquid metal at the time of being poured into mold”. The team is also satisfied with the preliminary results obtained from the first casting tests, “although we still have to carry out a more detailed study”.

Coil demonstrator made of martensitic steel by LMD (left) and structure for the fastening of the coil (center); and Zamak casting tests for matrix development (right).

Part of the developments made so far have been presented at the “32nd Symposium on Fusion Technology”, held at the end of September 2022 in Dubrovnik (Croatia), along with this poster.