AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

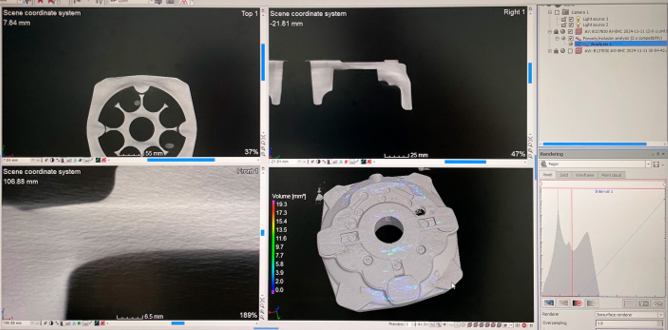

Advanced tomographic inspection for the development of new products and processes

Supporting Industry R&D Advanced tomographic inspection for the development of new products and processes Metrological resolution High capacity for detecting

KASANDRA® – Software for a real-time prediction of the risk of defect apparition

Iron Foundry KASANDRA® Real time predictive simulation for spheroidal graphite iron foundry High yield designs and a zero defect production

SMART DOSING SYSTEM – Mg treatment manager

High yield foundry solutions SDS – SMART DOSING SYSTEM Intelligent Mg dosing manager for cored wire and standard tundish cover

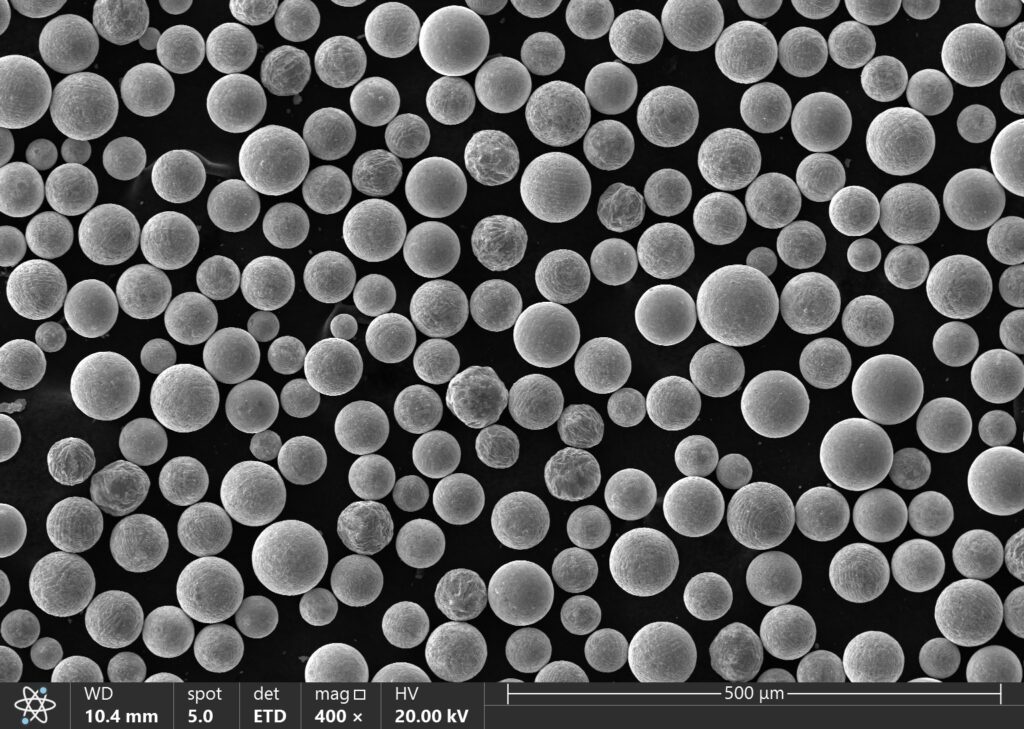

Atomized Ni-Ti powders for reactive paint

NEW MATERIALS Atomized Ni-Ti3 powder Ad-hoc metallic powders for developing protective surfaces. More information Promoting the hybridization of manufacturing technologies.

SENTINEL® – Predictive control of manufacturing process by means of Artificial Intelligence

INTELLIGENT MANUFACTURING SENTINEL® Predictive control of the manufacturing process of metallic components. Ensure the efficiency and the outcome of your

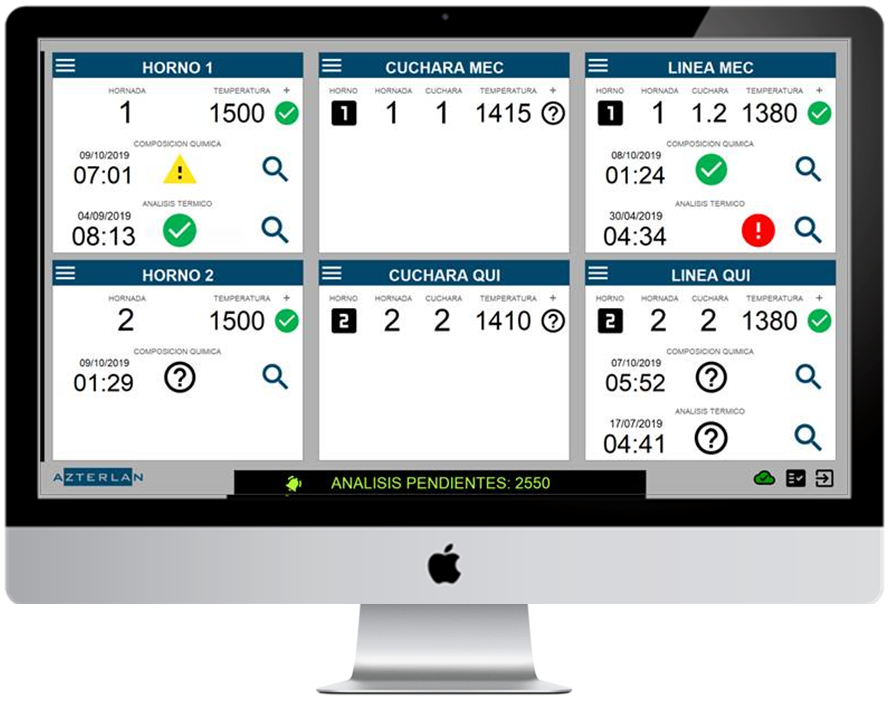

PDManager®- Digitalization, traceability and storage of foundry process data

process data management PDManager® Digitalization, correlation, traceability and storage of the relevant castings manufacturing process data. Modular system to control

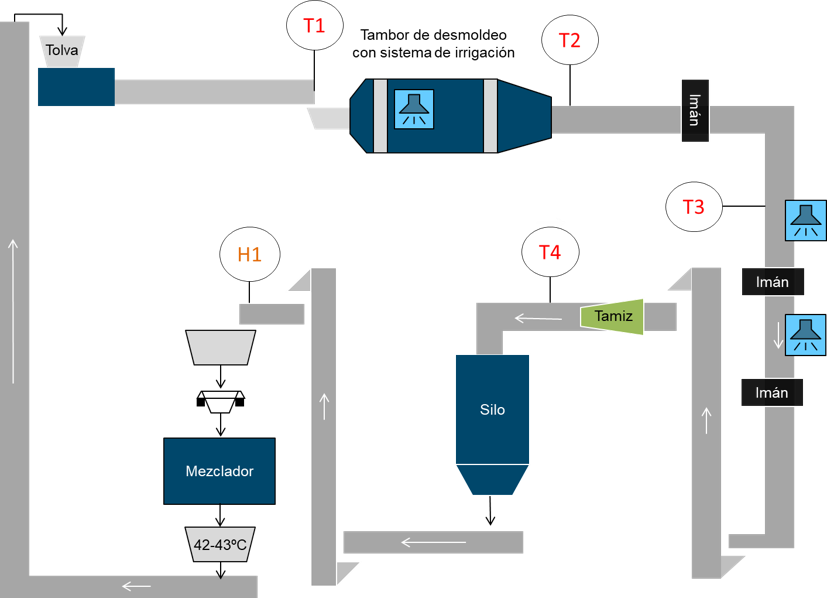

Intelligent water dosing system for conditioning the return sand

DIGITAL TWIN Intelligent water dosing system for return sand conditioning Ensure the optimal conditions for recovered sand, without the need

DyMetriCS® – Dynamic mold mismatch control

Intelligent manufacturing DyMetriCS® System to control the dynamic mismatch of vertical foundry molds Avoid finishing operations that do not add

SECONDARY ALUMINUM WITH IMPROVED PROPERTIES

NEW SUSTAINABLE MATERIALS Secondary Aluminum with advanced mechanical properties New strategies to upgrade recycled aluminum alloys. More information A new

THERMOLAN® – Metallurgical quality prediction for iron casting

Iron Foundry THERMOLAN® Ensure the quality of your castings from the melt in less than 60 seconds. Thermal analysis system

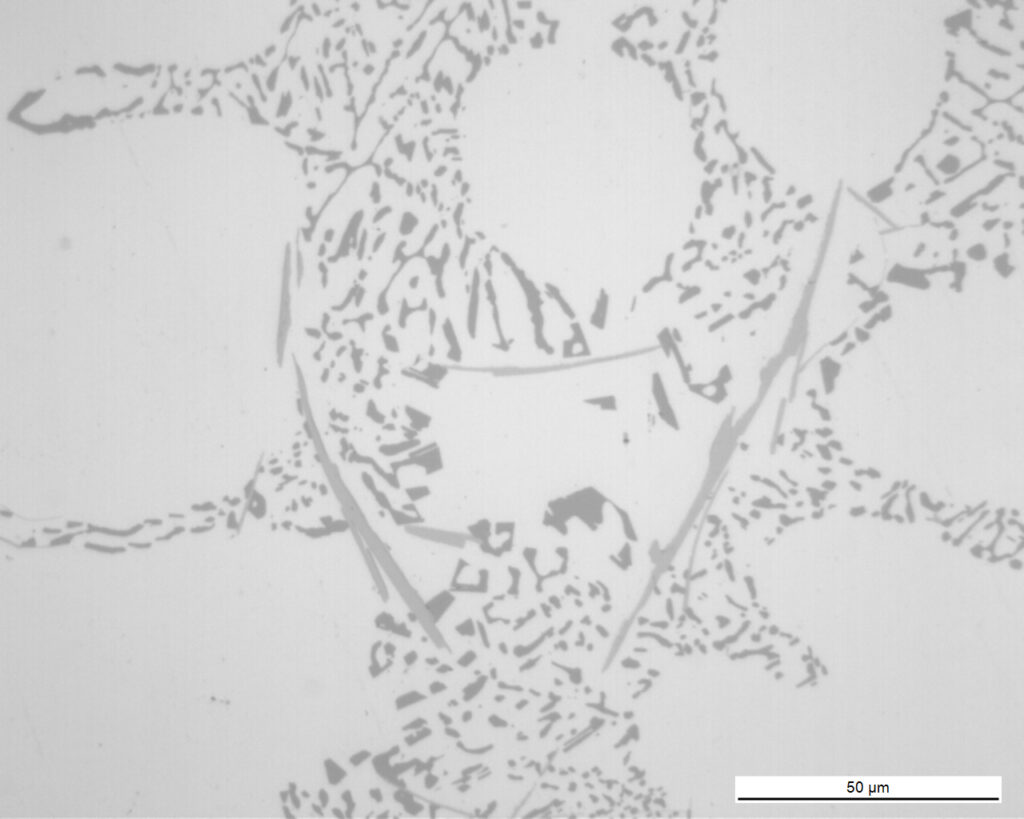

HE:PROTECT – Advanced development of steel materials and components for application in underwater environments

service life improvement HE:PROTECT Advanced development of steel materials and components for aquatic environments. Reduce premature failures caused by Hydrogen

METALLURGICAL COMPENSATOR – Promoting graphitization in the last stages of solidification

New manufacturing technologies METALLURGICAL COMPESATIVE PRODUCT Promotes late graphitization to ensure the quality of ductile cast iron components >80% reduction

ALU-V® – Vacuum generation system for HPDC manufacturing

Intelligent manufacturing Alu-V® System to extract gases from injected aluminum molds Reduce porosity and defects in parts manufactured by HPDC.

Method for preparing a stainless steel additive coating

The present invention refers to a method for obtaining a stainless steel additive coating by deposition in a single coating

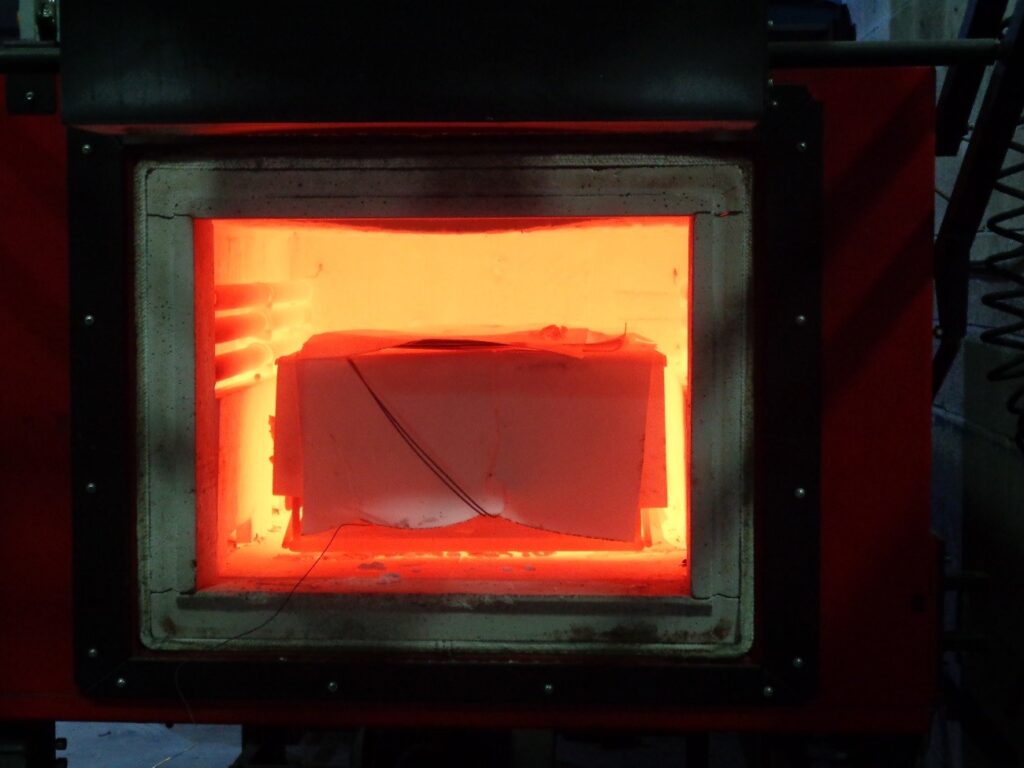

TREAT- Optimization of Heat Treatments (methodology)

Sustainable manufacturing processes TREAT Efficient Heat Treatments Methodology for the development of optimized thermal treatments More information Design of sustainable

HTSTEELS – Super-refractory stainless steels

New Material HTSteels New family of super-refractory stainless steels Patented technology Improved resistance to creep and thermal fatigue Fit for