AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

Metallurgical process control to optimize iron castings

20/01/2021 After thousands of years among us, foundry still encloses many mysteries that might lead us to think that its

REVaMP. Retrofitting equipment for efficient use of variable feedstock in metal making processes

Project complete 0% 0 Start date Horizon 2020 Funded by 869882 grant agreement number 0 End date Metals can be

Digital Twins workshop

AZTERLAN’s Industry 4.0 expert and head of Intelligent Manufacturing Technologies team PhD Javier Nieves presented some of the keys towards

Effect of titanium in the nucleation process of spheroidal and compacted graphite cast iron

Nucleation and growth phenomena that control the solidification directly affect the soundness and the mechanical properties of the castings. Understanding

Microstructure Changes During Solidification of Cast Irons: Effect of Chemical Composition and Inoculation on Competitive Spheroidal and Compacted Graphite Growth

Amongst the most important graphite shapes, nodules and compacted particles are of particular interest as they can coexist in castings

Influence of different inoculants on the nucleation potential and the contraction ability of the ductile iron

The use of advanced control systems based on cooling curves allows to analyse the characteristics of the melt in real

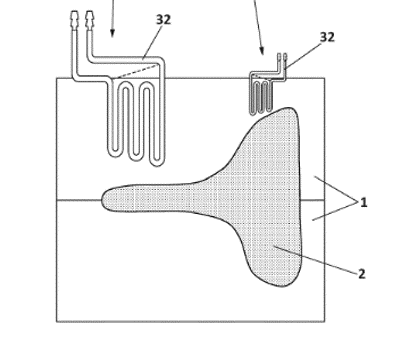

Device and method for improved cooling of a metallic alloy in a sand mold

Abstract: The device comprises a sand mold with an inner cavity fillable with a metallic alloy to be solidified inside

Shaping the foundry of the future by means of the “perfect casting”

03/09/2019 In the month of June took place in Dusseldorf a new edition of the GIFA international foundry exhibition, which

Chunky graphite in spheroidal graphite iron: Review of recent results and definition of an predicting index

Graphite degeneracy in heavy-section spheroidal graphite cast irons is mostly associated with the formation of chunky graphite which consists of

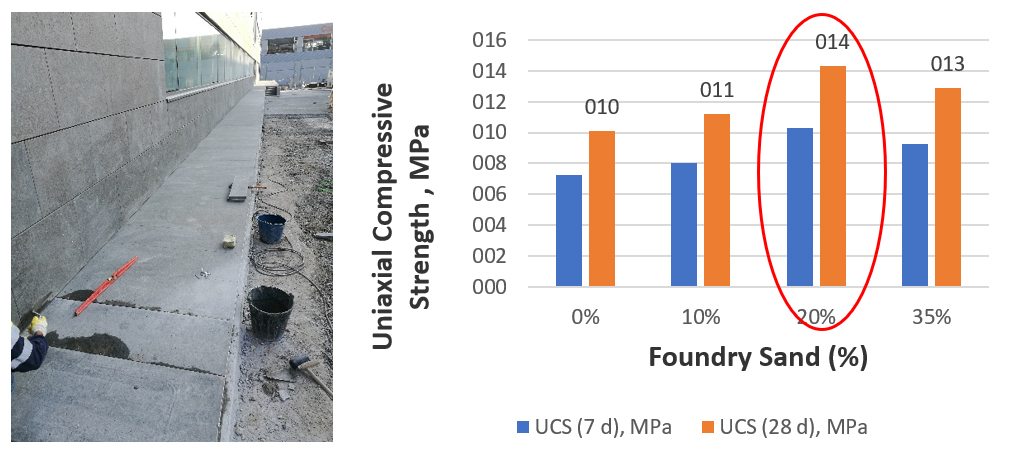

Validation of the usage of spent foundry sand as a fine aggregate for construction applications

27/07/2019 Lead by the IK4-AZTERLAN Metallurgy Research Centre and with the participation of an outstanding consortium of companies and entities,

Relation between the damping capacity and tensile strength of alloyed nodular cast irons for braking system components

The automotive industry has been conducting researches and continuously improving components aiming to decrease their weight maintaining high mechanical properties

Corrosion: a common issue

If we would ask someone who is not familiar with the science of materials or the metallurgical industry what corrosion

Spent foundry sand valorization in construction sector through the validation of high-performance applications

Disposal of spent foundry sand (SFS) is one of the most pressing environmental concerns the metal casting industry faces nowadays.

The Influence of Alloying Elements on Damping Capacity of Nodular Cast Irons for Braking System Components

The brake noise is one of the highest incidences of complaints from OEM’s customers, causing problems such as passenger disappointment

Growth of spheroidal graphite on nitride nuclei: disregistry and crystallinity during early growth

The graphite phase resulting from the stable solidification of iron-carbon-silicon alloys can have a variety of morphologies, from lamellar to

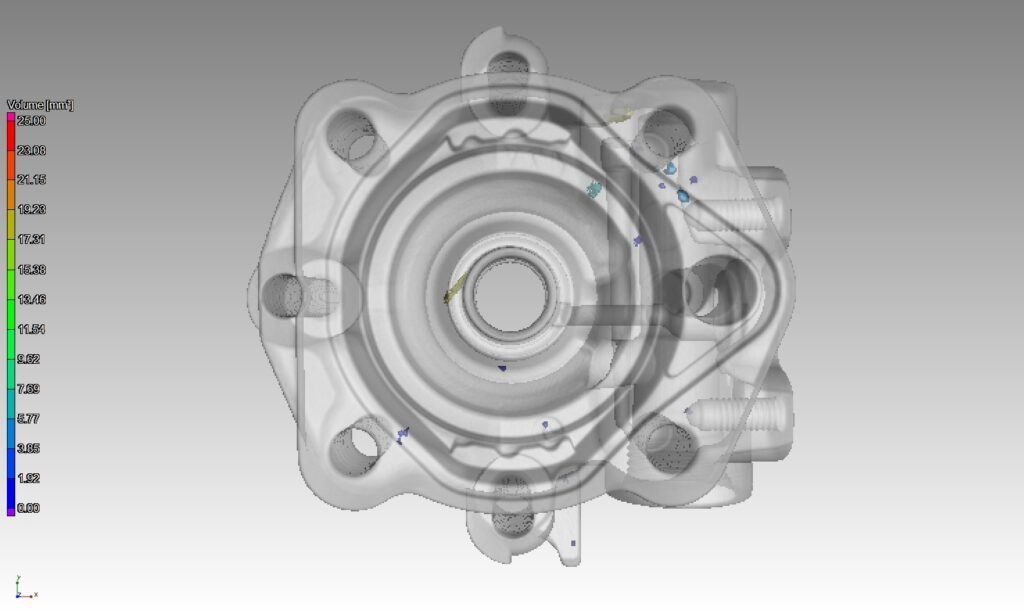

Non Destructive Testing by means of X-ray technologies: main clues of Radioscopy and Computed Axial Tomography tests

The inspection of solid materials and components (metallic and non-metallic) by means of X-ray technologies allows to check their internal