AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

Surface modification of ductile iron produced by an innovative in-situ casting technique

In this study, a chromium carbide layer was fabricated by an in-situ casting technique on ductile iron cast components. The

90 years of thermal analysis as a control tool in the melting of cast iron

Since its first literature mention in conjunction with cast iron in 1931 by Esser and Lautenbusch, thermal analysis (TA) has

Modelling of compacted graphite cast iron solidification-Discussion of microstructure parameters

A melt maintained for hours in a press pour unit allowed the following changes over time from spheroidal graphite to

Effect of antimony on the nucleation process of spheroidal graphite iron

To further understand the influence of subversive elements on the nucleation process of spheroidal graphite, melts with antimony contents ranging

Reply to Comment on “Recent Developments in Understanding Nucleation and Crystallization of Spheroidal Graphite in Iron-Carbon-Silicon Alloys”

In their comments, Lacaze and Castro-Roman [1] seek to correct some statements that we made in our recent paper published

Graphite Nucleation in Compacted Graphite Cast Iron

During the last several decades, a multitude of theories have attempted to explain the process of graphite nucleation in lamellar

Recent Developments in Understanding Nucleation and Crystallization of Spheroidal Graphite in Iron-Carbon-Silicon Alloys

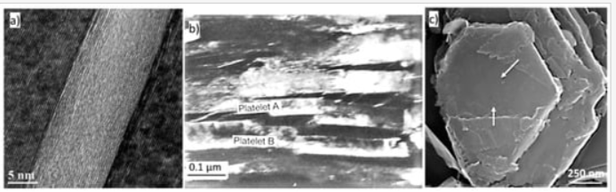

The last decade has witnessed significant research efforts directed to the understanding of nucleation and crystallization of graphite and associated

Quantitative analysis of the effect of inoculation and magnesium content on compacted graphite irons – Experimental approach

In many industrial domains, compact graphite cast irons are developing rapidly at the expense of lamellar graphite irons. The formation

Effect of Magnesium on the Solid-State Nucleation and Growth of Graphite During Annealing of White Iron

It is well-established that growth of spheroidal graphite occurs in several stages such as directly in the liquid, in the

Digital Twins workshop

AZTERLAN’s Industry 4.0 expert and head of Intelligent Manufacturing Technologies team PhD Javier Nieves presented some of the keys towards

Effect of titanium in the nucleation process of spheroidal and compacted graphite cast iron

Nucleation and growth phenomena that control the solidification directly affect the soundness and the mechanical properties of the castings. Understanding

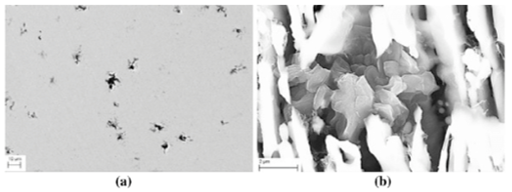

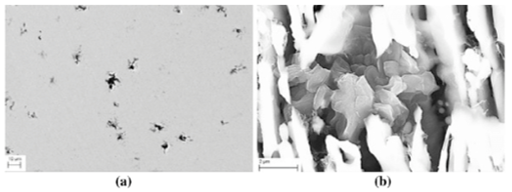

Microstructure Changes During Solidification of Cast Irons: Effect of Chemical Composition and Inoculation on Competitive Spheroidal and Compacted Graphite Growth

Amongst the most important graphite shapes, nodules and compacted particles are of particular interest as they can coexist in castings

Influence of different inoculants on the nucleation potential and the contraction ability of the ductile iron

The use of advanced control systems based on cooling curves allows to analyse the characteristics of the melt in real

Comparison of Hot Cracking Susceptibility of TIG and Laser Beam Welded Alloy 718 by Varestraint Testing

Reduced hot cracking susceptibility is essential to ensure the flawless manufacturing of nickel superalloys typically employed in welded aircraft engine

Forging residual heat exploitation feasibility for annealing treatments in space restricted lay-outs

Taking advantage of the residual heat in forged components right after forging, by means of loading them directly into a

Experimental validation of steel slag as thermal energy storage material in a 400 kWht prototype

Packed bed systems have been proposed in the last years as a promising thermal energy storage alternative to reduce the