AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

Graphite Nucleation in Compacted Graphite Cast Iron

During the last several decades, a multitude of theories have attempted to explain the process of graphite nucleation in lamellar

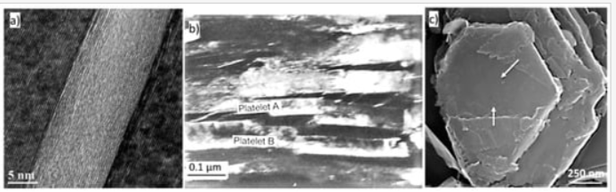

Recent Developments in Understanding Nucleation and Crystallization of Spheroidal Graphite in Iron-Carbon-Silicon Alloys

The last decade has witnessed significant research efforts directed to the understanding of nucleation and crystallization of graphite and associated

Quantitative analysis of the effect of inoculation and magnesium content on compacted graphite irons – Experimental approach

In many industrial domains, compact graphite cast irons are developing rapidly at the expense of lamellar graphite irons. The formation

Effect of Magnesium on the Solid-State Nucleation and Growth of Graphite During Annealing of White Iron

It is well-established that growth of spheroidal graphite occurs in several stages such as directly in the liquid, in the

Effect of titanium in the nucleation process of spheroidal and compacted graphite cast iron

Nucleation and growth phenomena that control the solidification directly affect the soundness and the mechanical properties of the castings. Understanding

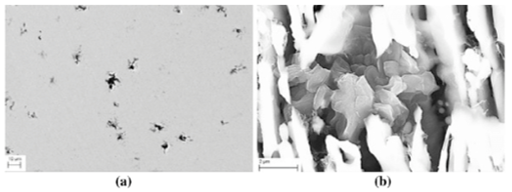

Microstructure Changes During Solidification of Cast Irons: Effect of Chemical Composition and Inoculation on Competitive Spheroidal and Compacted Graphite Growth

Amongst the most important graphite shapes, nodules and compacted particles are of particular interest as they can coexist in castings

Influence of different inoculants on the nucleation potential and the contraction ability of the ductile iron

The use of advanced control systems based on cooling curves allows to analyse the characteristics of the melt in real

Comparison of Hot Cracking Susceptibility of TIG and Laser Beam Welded Alloy 718 by Varestraint Testing

Reduced hot cracking susceptibility is essential to ensure the flawless manufacturing of nickel superalloys typically employed in welded aircraft engine

Forging residual heat exploitation feasibility for annealing treatments in space restricted lay-outs

Taking advantage of the residual heat in forged components right after forging, by means of loading them directly into a

Experimental validation of steel slag as thermal energy storage material in a 400 kWht prototype

Packed bed systems have been proposed in the last years as a promising thermal energy storage alternative to reduce the

Failure Analysis Based Redesign of Furnace Conveyor System Components: A Case Study

Any manufacturing equipment designed from scratch requires a detailed follow-up of the performance for the first units placed in service

Chunky graphite in spheroidal graphite iron: Review of recent results and definition of an predicting index

Graphite degeneracy in heavy-section spheroidal graphite cast irons is mostly associated with the formation of chunky graphite which consists of

Relation between the damping capacity and tensile strength of alloyed nodular cast irons for braking system components

The automotive industry has been conducting researches and continuously improving components aiming to decrease their weight maintaining high mechanical properties

Compositional Modification of Tool Steel to Improve Its Wear Resistance

The high hardness property of hot working steel is not always an advantage as several defects can occur, which reduce

Spent foundry sand valorization in construction sector through the validation of high-performance applications

Disposal of spent foundry sand (SFS) is one of the most pressing environmental concerns the metal casting industry faces nowadays.

The Influence of Alloying Elements on Damping Capacity of Nodular Cast Irons for Braking System Components

The brake noise is one of the highest incidences of complaints from OEM’s customers, causing problems such as passenger disappointment