AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

Diagnosis and failure analysis

field of specialization Diagnosis and Failure Analysis Forensic study of the origin of in-service failures, functional problems and manufacturing defects.

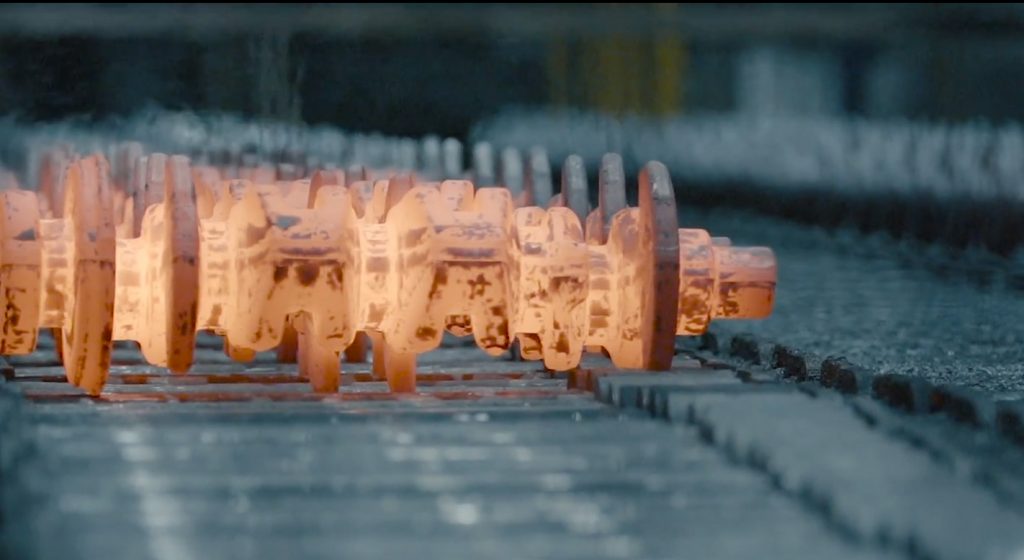

In-line heat treatment of forgings

Efficient manufacturing processes In-line heat treatmet of forged parts Use of the residual heat of parts for a more efficient

Advanced management of industrial waste

Field of specialization Advanced management of industrial waste New valorization routes Waste classification Minimization strategies More information Strategies to improve

New generation of digital material for automotive components

With the application of Industry 4.0 technology, a new generation of advanced materials is developing in the world of safety

The Role of Selenium on the Formation of Spheroidal Graphite in Cast Iron

Sulfur, an element that belongs to group 16 (chalcogens) of the periodic table, is an excellent promoter of nucleation substrates

Influence of graphite morphology on the corrosion behaviour of cast irons for automotive industry

Cast irons are widely used in the automotive industry due to its excellent castability, fluidity, machinability and wear resistance. Particularly,

When is a Cast Iron Eutectic?

The literature often mentions that cast irons that appear eutectic by thermal analysis are hypereutectic if one refers to the

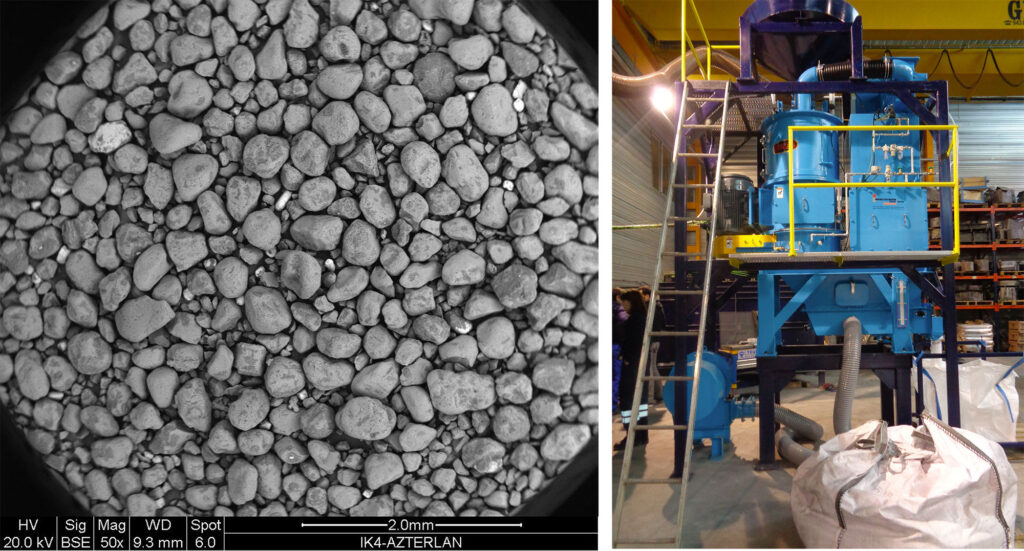

Study of the effect of commercial inoculants in high silicon cast iron components

High silicon alloys have experienced a significant growth in the last few years because of their homogeneous structure, very good

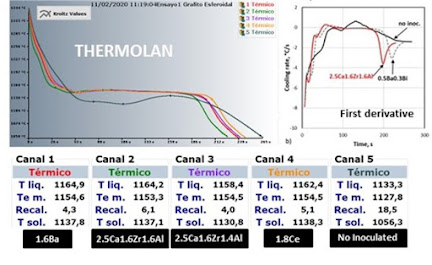

Science behind KASANDRA®

This article shows the scientific foundations on which Kasandra® predictive software is based. Along with this, a CASE STUDY is

Correction to: 90 years of thermal analysis as a control tool in the melting of cast iron

Since its first literature mention in conjunction with cast iron in 1931 by Esser and Lautenbusch, thermal analysis (TA) has

Nodule Count, End of Solidification Cooling Rate, and Shrinkage Porosity Correlations in High Silicon Spheroidal Graphite Iron

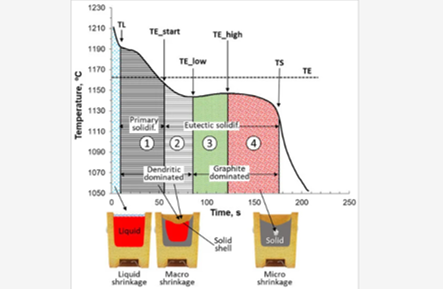

High-silicon spheroidal graphite (SG) irons present higher changes of density during the solidification process when compared to normal SG irons.

Quantitative Analysis of Solidification of Compacted Graphite Irons – A Modelling Approach

Several X-ray topography studies which have appeared recently in the literature show compacted graphite in cast iron consisting of coarse

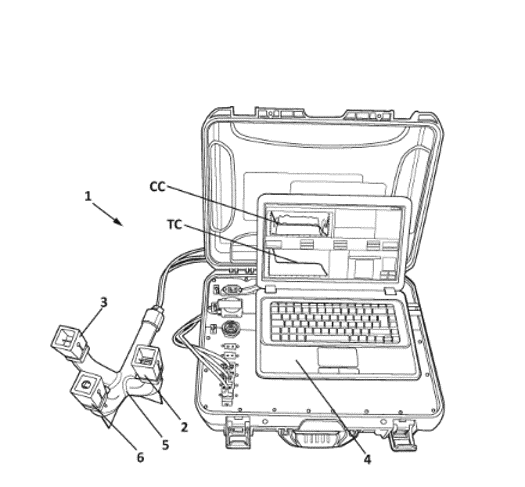

Method to determine the carbon equivalent content of a cast iron alloy having a hypereutectic composition and equipment to carry it out

The invention relates to a methodology based on thermal analyisis to determine the carbon equivalent content of a cast iron

Chunky Graphite in Low and High Silicon Spheroidal Graphite Cast Irons–Occurrence, Control and Effect on Mechanical Properties

Thermal analysis is largely used in cast-iron foundry shops as a means to check melt preparation before casting. It has

Study of Graphite Nucleation in High Sulfur Ductile Irons

It is well known that sulfur is an excellent promoter of graphite and plays an important role in its formation.

Determination of Microshrinkage Risk Index in Ductile Cast Iron Production

One recurrent problem in the foundry industry producing ductile iron castings for automotive industry is the presence of defects of