AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

Probing the correlation between corrosion resistance and biofouling of thermally sprayed metallic substrata in the field

The correlation between inherent corrosion resistance and biofouling was investigated for five different metallic coatings. Steel panels thermally spray-coated with

Tensile properties and fracture toughness at service temperatures of an optimized pearlitic ductile iron alloy for automotive crankshafts

Cast iron and forged steel have competed against each other for many years for different industrial applications. Crankshafts are one

Ablation technology applied to A356 alloys compared with conventional casting processes

Because ablation differs from conventional casting, some conventional metallurgical concepts, such as the relationship among secondary dendrite arm spacing (SDAS),

New scenario for high temperature performance materials and and components

This workshop (which was held online) gathered some of the latest research and innovation in the field of materials and

Study of the effect of commercial inoculants in high silicon cast iron components

Las aleaciones de alto silicio han vivido un significativo auge en los últimos años debido a que presentan una estructura

Effect of the magnesium treatment on the nucleation potential of ductile iron

It is well known that the metallurgical quality and nucleation potential of a cast iron are influenced by a series

Combustion of a Solid Recovered Fuel (SRF) Produced from the Polymeric Fraction of Automotive Shredder Residue (ASR)

The use of alternative fuels derived from residues in energy-intensive industries that rely on fossil fuels can cause considerable energy

New generation of digital material for automotive components

With the application of Industry 4.0 technology, a new generation of advanced materials is developing in the world of safety

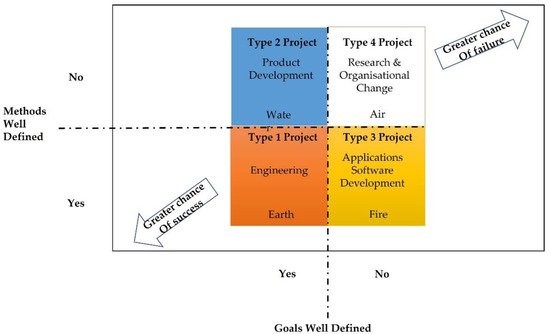

Antifragile Philosophy in R&D Projects: Applying Q Methodology and the Possibility of Open Innovation

Antifragile philosophy can be the key to improving the management of organizations that base their activity on research and development

Influence of Minor Alloying Element Additions on the Crack Susceptibility of a Nickel Based Superalloy Manufactured by LPBF

Inconel 738LC (IN738LC) is a nickel-based superalloy specially used in the hot section components of turbine engines. One of its

The Role of Selenium on the Formation of Spheroidal Graphite in Cast Iron

Sulfur, an element that belongs to group 16 (chalcogens) of the periodic table, is an excellent promoter of nucleation substrates

Influence of graphite morphology on the corrosion behaviour of cast irons for automotive industry

Cast irons are widely used in the automotive industry due to its excellent castability, fluidity, machinability and wear resistance. Particularly,

Finite difference modelling for understanding the hydrogen assisted cracking in virtual slow strain rate tensile tests

Different hydrogen-induced cracking patterns have been observed on two construction steels belonging to the same strength grade for mooring offshore

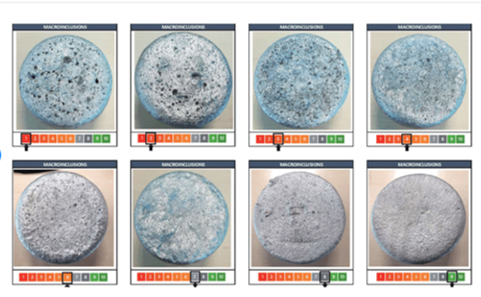

Comparative study of the metallurgical quality of primary and secondary alsi10mnmg aluminium alloys

The use of secondary aluminium is increasingly being promoted in the automotive industry for environmental reasons. The purpose of this

Improvement of the secondary aluminium metallurgical quality by means of an adequate melt treatment

This work has the purpose to demonstrate that if an adequate melt treatment is applied, it is possible to obtain

When is a Cast Iron Eutectic?

The literature often mentions that cast irons that appear eutectic by thermal analysis are hypereutectic if one refers to the