AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

Study of the corrosion resistance of powder mixture coatings carried out by means of LMD

This study is carried out with the objective of demonstrating the feasibility of using LMD technology to regulate the resistance

Influence of the Laser Deposited 316L Single Layers on Corrosion in Physiological Media

A multilayer laser-deposited lining of AISI 316L stainless steel makes a regular structural steel surface corrosion resistant in physiological media.

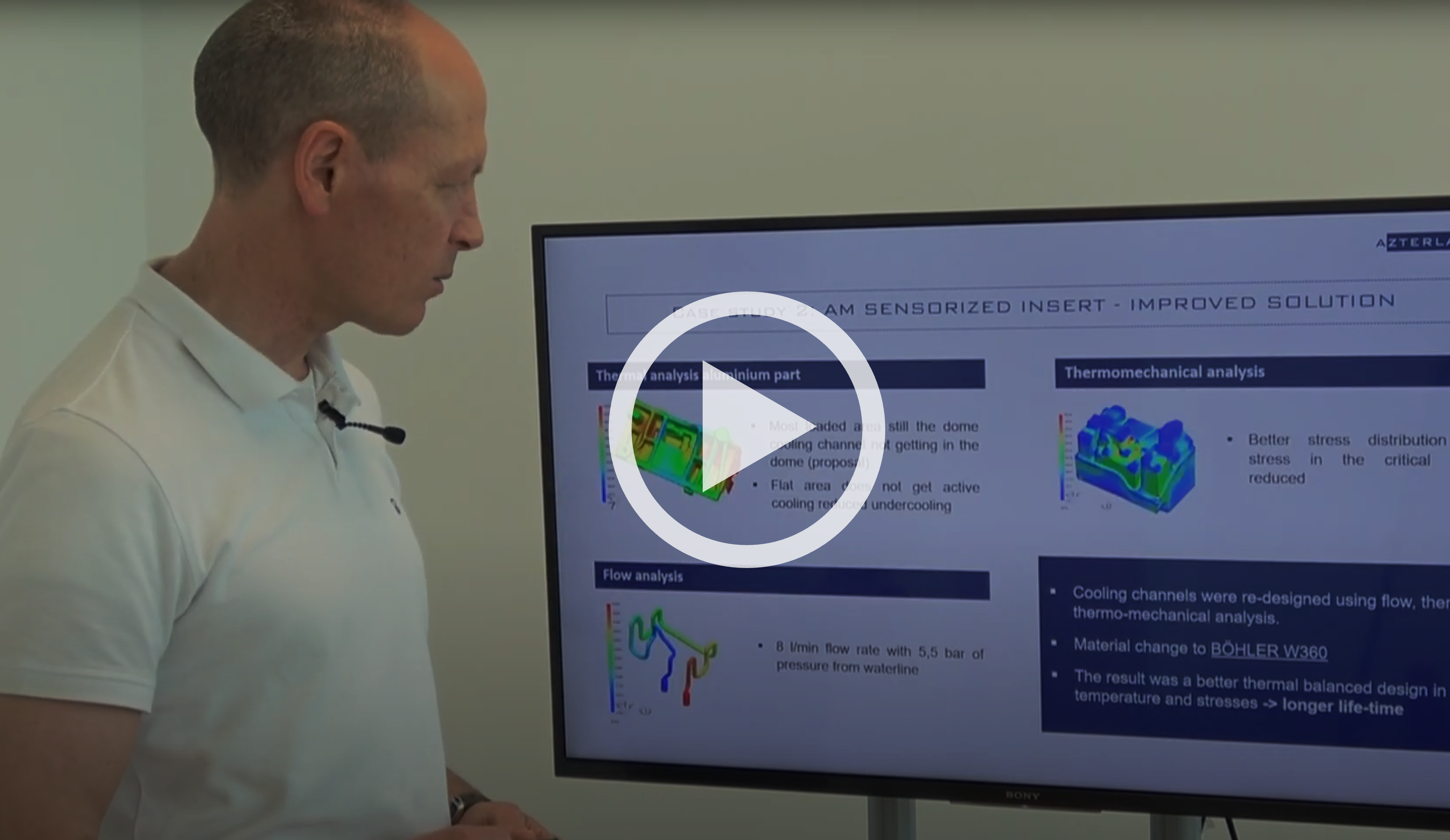

Additive Manufactured inserts for Industry 4.0 HPDC Foundries

Researcher Emili Barbarias explains two case studies regarding advanced monitoring and control of High Pressure Die Casting (HPDC) process developed

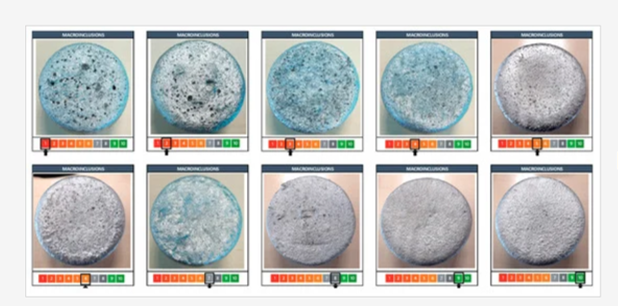

Comparative Study of the Metallurgical Quality of Primary and Secondary AlSi10MnMg Aluminium Alloys

The use of secondary aluminium is increasingly being promoted in the automotive industry for environmental reasons. The purpose of this

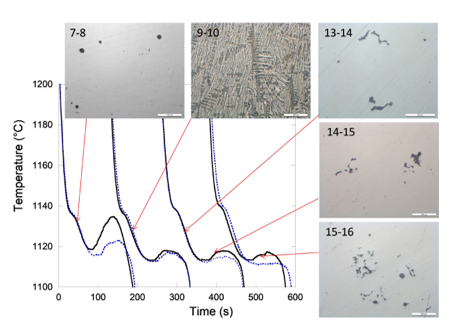

Successive steps of growth of compacted graphite in cast irons

Holding during 8 hours a melt prepared for casting SGI leads to fading of the spheroidizing treatment and thus to

Formability study of 2198 aluminium alloy for hot stamping

The aim of the present work is to assess the formability of the 2198 aluminum alloy for hot stamping applications

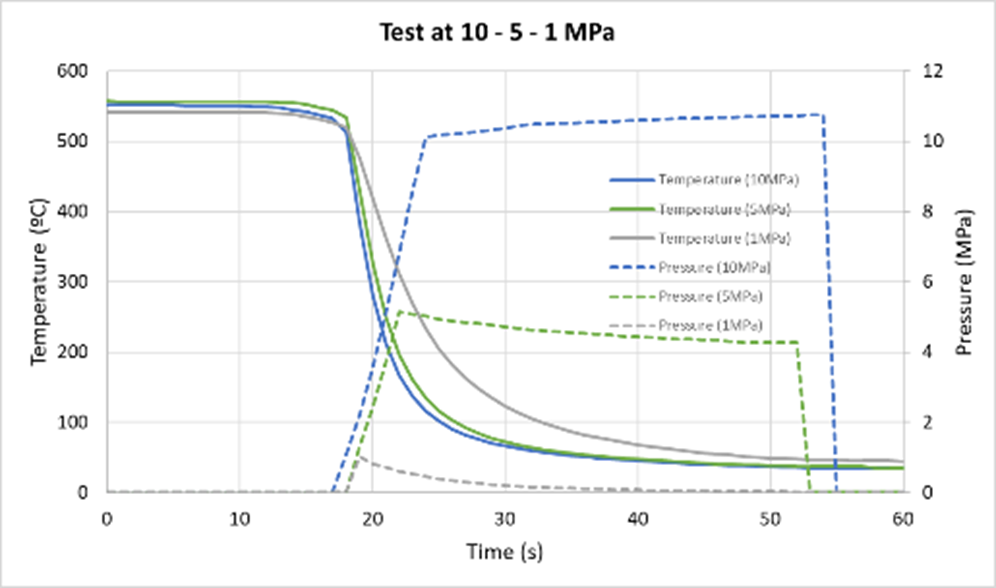

On the effect of testing setups on Aluminum alloys Interfacial Heat Transfer Coefficient Measurement

Sheet metal to die steel Interfacial Heat Transfer Coefficient (IHTC) is closely related to the cooling rate achieved in hot

Evolution of hot stamping technology: a bibliometric review

Today’s huge automotive industry requires continuous innovations. In this sense, numerous publications on new materials or developments which can provide

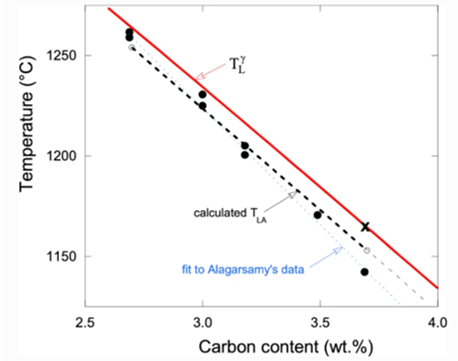

Is Thermal Analysis Able to Provide Carbon and Silicon Contents of Cast Irons?

The determination of silicon and carbon contents by thermal analysis is based on the recording of a cooling curve of

A Smart Digital Twin to Stabilize Return Sand Temperature without Using Coolers

In order to ensure the optimal state of recovered molding sand inside a foundry, it is necessary to avoid temperature

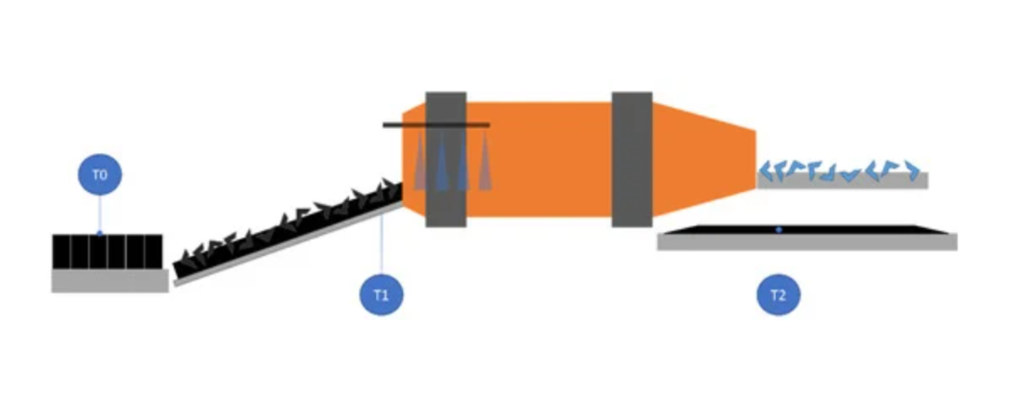

Chemical Composition and Melt Treatment Optimization of 5XXX and 6XXX Alloys for Ablation Technology

One of the most interesting capabilities of ablation technology is its capability to manufacture uncastable alloys such as alloys of

Influence of the Holding Time in the Heating/Pouring Unit on the Metallurgical Quality of Spheroidal Graphite Iron

The final metallurgical quality of a ductile iron is determined by the components of the metallic charge, as well as

New ductile cast iron digital grades for automotive components

This research paper demonstrate that new cast iron grade materials can be developed aided by an expert digital twin (manufacturing

Towards the Prediction of Tensile Properties in Automotive Cast Parts Manufactured by LPDC with the A356.2 Alloy

Aluminum-silicon-magnesium alloys are commonly used in the automotive industry to produce structural components. Among usual quality controls of produced castings,

The effect of the substitution of Silicon by Aluminum on the properties of lamellar graphite iron

In cast iron, silicon and aluminum are elements that promote graphite precipitation and strengthen the alloy by solid solution. In

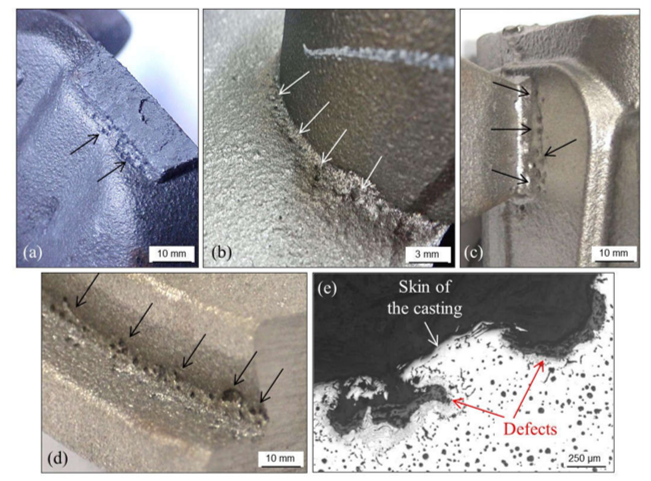

Casting Defects in Sand-Mold Cast Irons—An Illustrated Review with Emphasis on Spheroidal Graphite Cast Irons

Cast irons are known to be easy to shape by sand casting due to their high eutectic fraction. Despite this