AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

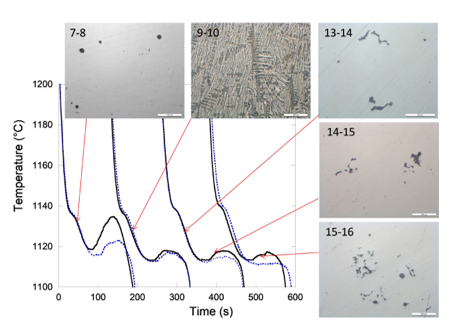

Successive steps of growth of compacted graphite in cast irons

Holding during 8 hours a melt prepared for casting SGI leads to fading of the spheroidizing treatment and thus to

Formability study of 2198 aluminium alloy for hot stamping

The aim of the present work is to assess the formability of the 2198 aluminum alloy for hot stamping applications

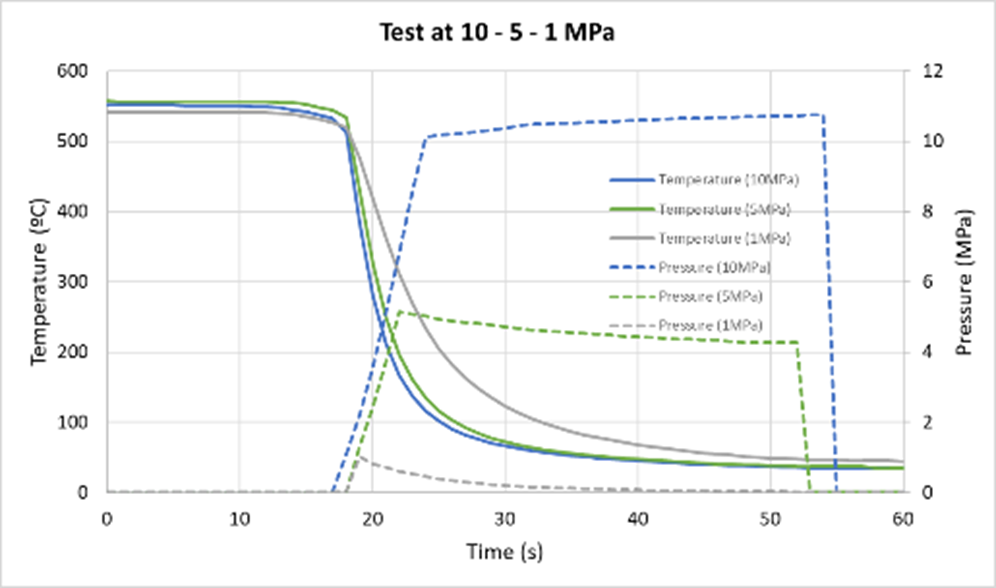

On the effect of testing setups on Aluminum alloys Interfacial Heat Transfer Coefficient Measurement

Sheet metal to die steel Interfacial Heat Transfer Coefficient (IHTC) is closely related to the cooling rate achieved in hot

Evolution of hot stamping technology: a bibliometric review

Today’s huge automotive industry requires continuous innovations. In this sense, numerous publications on new materials or developments which can provide

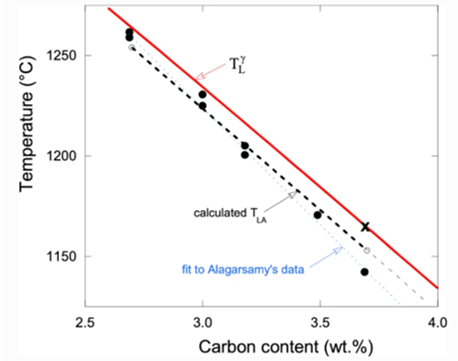

Is Thermal Analysis Able to Provide Carbon and Silicon Contents of Cast Irons?

The determination of silicon and carbon contents by thermal analysis is based on the recording of a cooling curve of

A Smart Digital Twin to Stabilize Return Sand Temperature without Using Coolers

In order to ensure the optimal state of recovered molding sand inside a foundry, it is necessary to avoid temperature

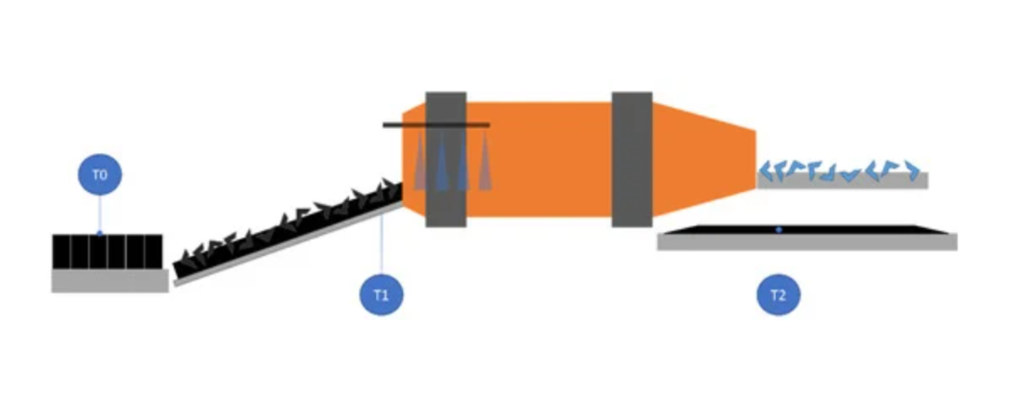

Chemical Composition and Melt Treatment Optimization of 5XXX and 6XXX Alloys for Ablation Technology

One of the most interesting capabilities of ablation technology is its capability to manufacture uncastable alloys such as alloys of

Influence of the Holding Time in the Heating/Pouring Unit on the Metallurgical Quality of Spheroidal Graphite Iron

The final metallurgical quality of a ductile iron is determined by the components of the metallic charge, as well as

New ductile cast iron digital grades for automotive components

This research paper demonstrate that new cast iron grade materials can be developed aided by an expert digital twin (manufacturing

Towards the Prediction of Tensile Properties in Automotive Cast Parts Manufactured by LPDC with the A356.2 Alloy

Aluminum-silicon-magnesium alloys are commonly used in the automotive industry to produce structural components. Among usual quality controls of produced castings,

The effect of the substitution of Silicon by Aluminum on the properties of lamellar graphite iron

In cast iron, silicon and aluminum are elements that promote graphite precipitation and strengthen the alloy by solid solution. In

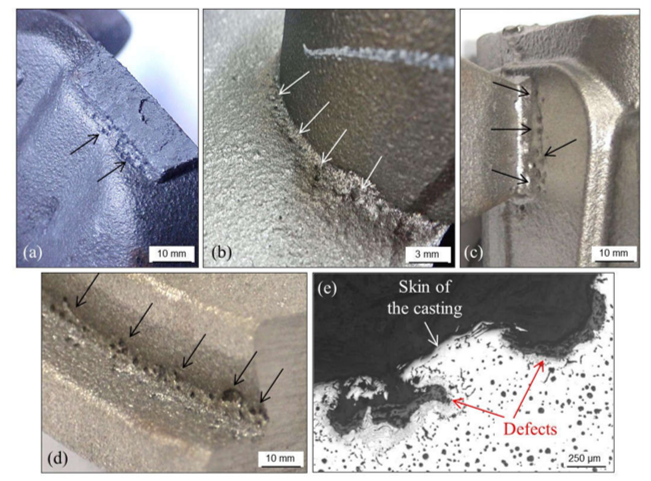

Casting Defects in Sand-Mold Cast Irons—An Illustrated Review with Emphasis on Spheroidal Graphite Cast Irons

Cast irons are known to be easy to shape by sand casting due to their high eutectic fraction. Despite this

Probing the correlation between corrosion resistance and biofouling of thermally sprayed metallic substrata in the field

The correlation between inherent corrosion resistance and biofouling was investigated for five different metallic coatings. Steel panels thermally spray-coated with

Tensile properties and fracture toughness at service temperatures of an optimized pearlitic ductile iron alloy for automotive crankshafts

Cast iron and forged steel have competed against each other for many years for different industrial applications. Crankshafts are one

Ablation technology applied to A356 alloys compared with conventional casting processes

Because ablation differs from conventional casting, some conventional metallurgical concepts, such as the relationship among secondary dendrite arm spacing (SDAS),

Study of the effect of commercial inoculants in high silicon cast iron components

Las aleaciones de alto silicio han vivido un significativo auge en los últimos años debido a que presentan una estructura