AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

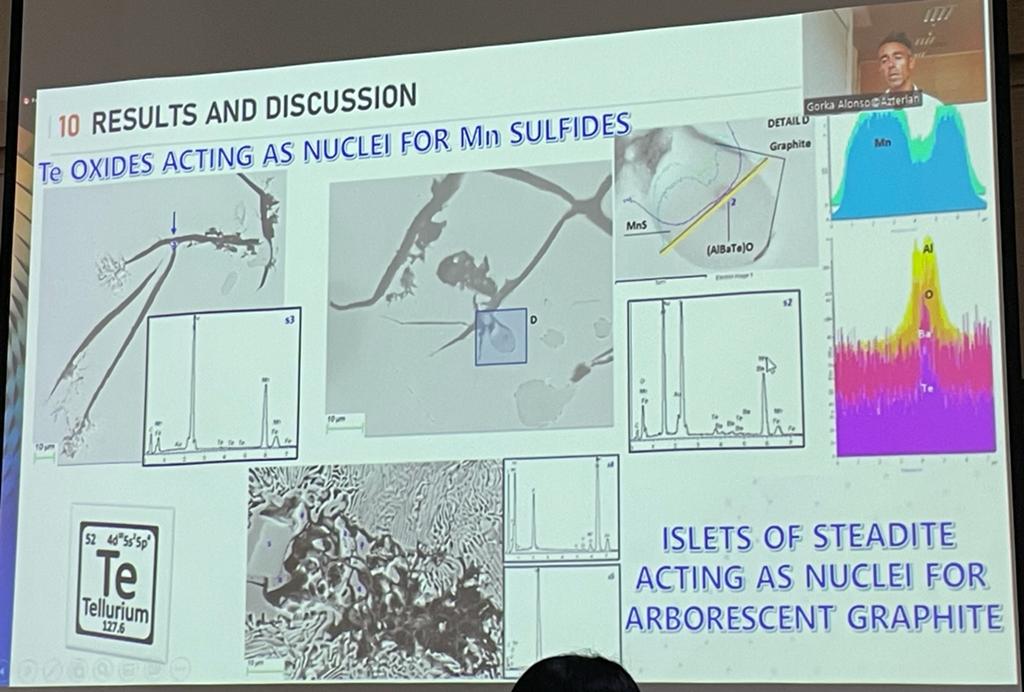

Mechanisms of Formation of Degenerated Graphite in Lamellar Graphite Cast Iron

The final morphology of graphite and its effect on the physical and mechanical properties of a cast iron, is highly

Optimization of ductile iron casting production by using advanced thermal analysis and simulation techniques

The use of advanced techniques to control cast iron manufacturing processes lead to important reductions of costs and improvements of

New EoL routes of Al Li aircraft integral LBW and FSW welded panels including new Cr free coatings

EoL of new aircraft integral welded panels of 3rd generation of Al-Li alloys welded between them by Laser Beam Welding

Pseudo-passive films on cast irons: A strategy to mitigate corrosion by acting directly on microstructure

The effect of the microstructure on the corrosion resistance of four grades of cast irons was studied in an alkaline

The Effects of Holding Time in the Heating/Pouring Unit on the Metallurgical Quality of Spheroidal Graphite Iron

The metallurgical quality of a ductile iron is determined by the components of the metallic charge, as well as by

Compact graphite iron’s real time manufacturing control by thermal analysis

This research work presents a real time nodularity control methodology by thermal analysis for compact graphite iron (CGI) production. It

A new approach of casting simulation tools integrated in the production line

The use of numerical simulation tools in the foundry is absolutely extended and it has been a strong support for

Mechanical properties optimization of as-cast ausferritic ductile iron as a function of section size and holding time

The ADI family shows the best resistance ductility relationship of the ductile iron materials due to an ausferritic microstructure. This

Study of the corrosion behavior of CRA cladded high strength steel for offshore service

Components subjected to corrosion in the Oil & Gas sector are frequently manufactured in Corrosion Resistant Alloys (CRA) over High

Simulation of hydrogen transport in ultra-high strength martensitic steels with zinc-nickel coating

-No information- Authors: A. Ravikumar (Helmholtz-Zentrum Hereon), C. Feiler (Helmholtz-Zentrum Hereon), D. Höche (Helmholtz-Zentrum Hereon), M. Zheludkevich (Helmholtz-Zentrum Hereon), M.

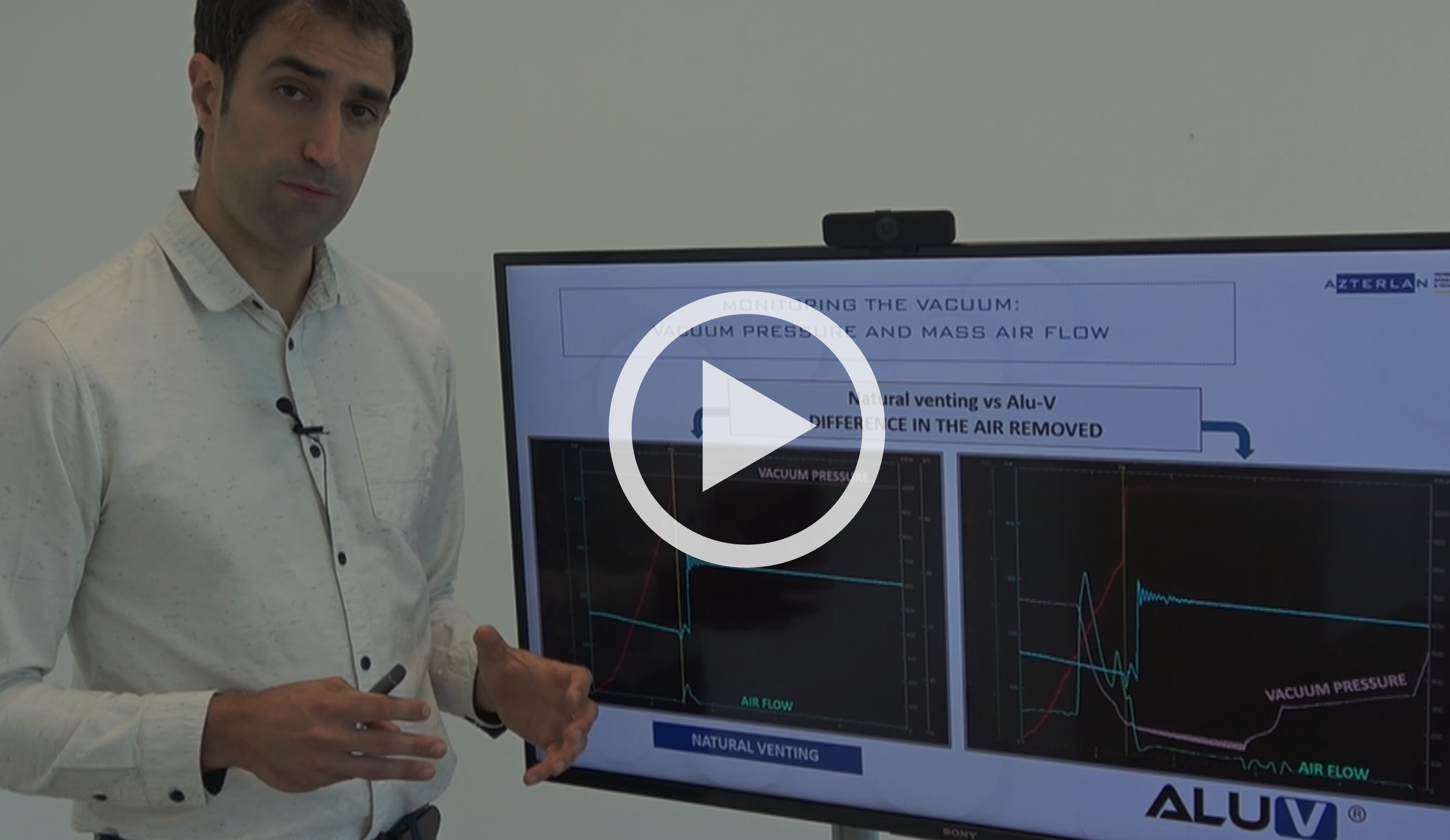

A sound vacuum system fully monitored to ensure the quality of the HPDC components

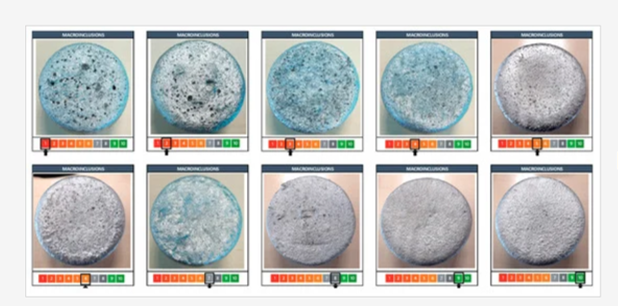

Gas porosity is an intrinsic feature of the HPDC process due to the fast metal injection that does not allow

Effect of cobalt on the mechanical properties of high silicon spheroidal graphite castings

In order to optimize the mechanical properties of spheroidal graphite cast iron, different alloying elements such as Nickel, Cobalt and

Study of the corrosion resistance of powder mixture coatings carried out by means of LMD

This study is carried out with the objective of demonstrating the feasibility of using LMD technology to regulate the resistance

Influence of the Laser Deposited 316L Single Layers on Corrosion in Physiological Media

A multilayer laser-deposited lining of AISI 316L stainless steel makes a regular structural steel surface corrosion resistant in physiological media.

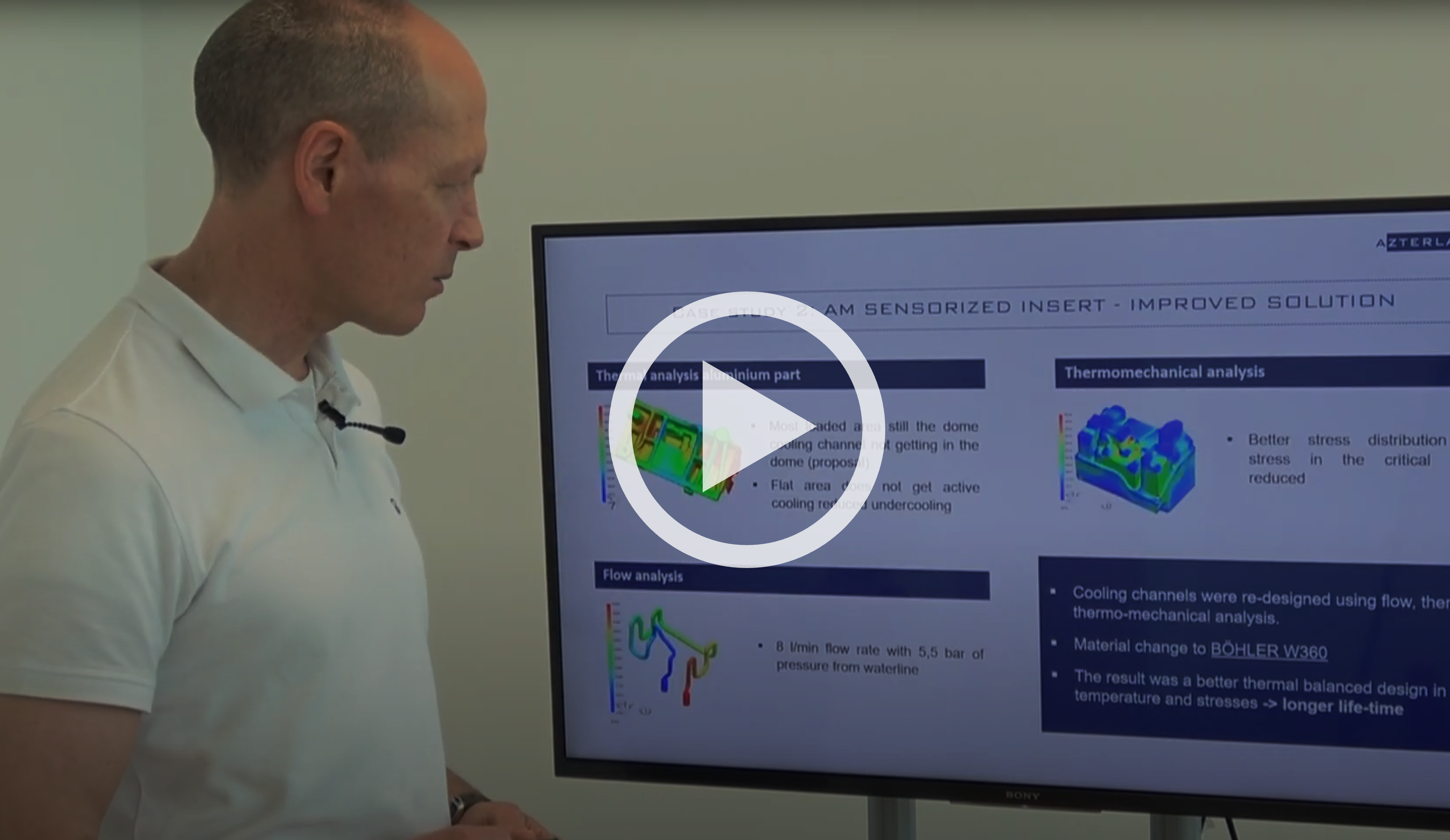

Additive Manufactured inserts for Industry 4.0 HPDC Foundries

Researcher Emili Barbarias explains two case studies regarding advanced monitoring and control of High Pressure Die Casting (HPDC) process developed

Comparative Study of the Metallurgical Quality of Primary and Secondary AlSi10MnMg Aluminium Alloys

The use of secondary aluminium is increasingly being promoted in the automotive industry for environmental reasons. The purpose of this