AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

Fatigue and fracture mechanics

Specialization field Detection, characterization and evolution of fatigue cracks Fatigue and fracture mechanics testing Certification of materials Dynamic testing /

METALLURGICAL COMPENSATOR – Promoting graphitization in the last stages of solidification

New manufacturing technologies METALLURGICAL COMPESATIVE PRODUCT Promotes late graphitization to ensure the quality of ductile cast iron components >80% reduction

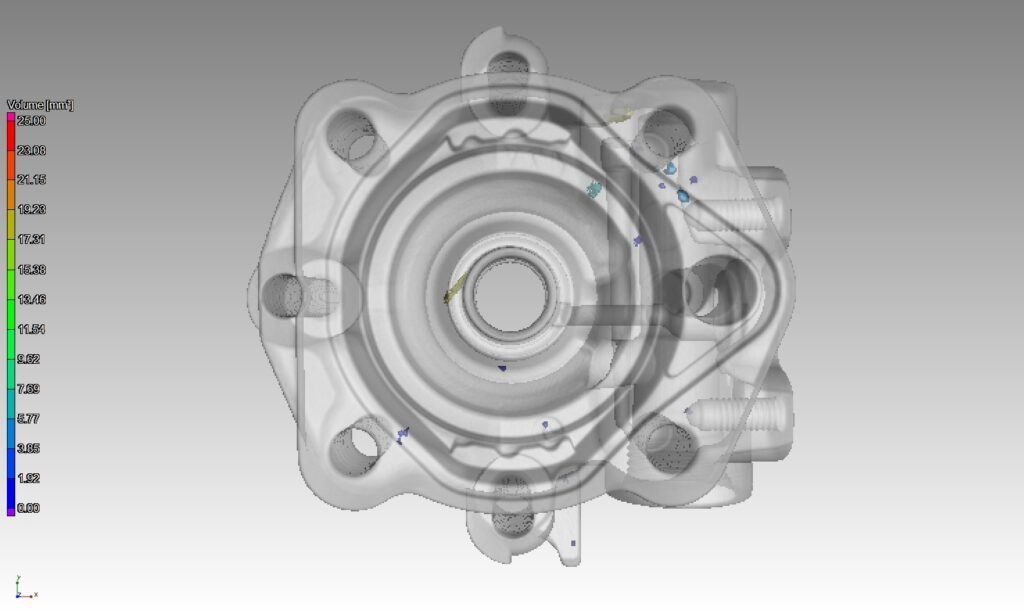

RADIOGRAPHIC INSPECTION

FEATURED TEST RADIOGRAPHIC INSPECTION High-precision 2D images to ensure the soundness of metallic components. More information The AZTERLAN radiographic inspection

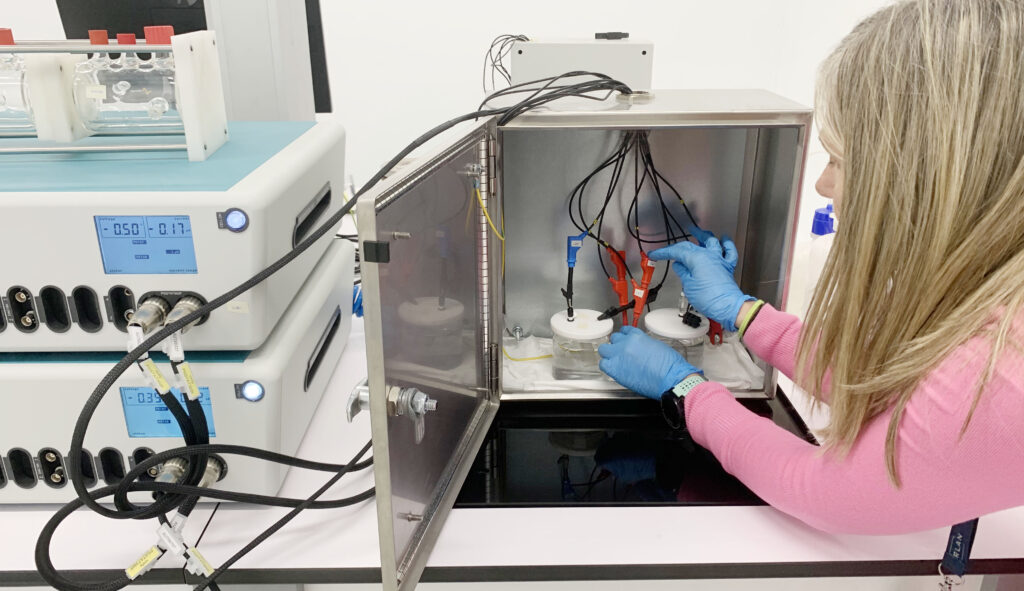

Hydrogen permeation assessment

ADVANCED CHARACTERIZATION HYDROGEN PERMEATION ASSESSMENT A key study to develop materials and coatings that are more resistant to hydrogen embrittlement

TREAT- Optimization of Heat Treatments (methodology)

Sustainable manufacturing processes TREAT Efficient Heat Treatments Methodology for the development of optimized thermal treatments More information Design of sustainable

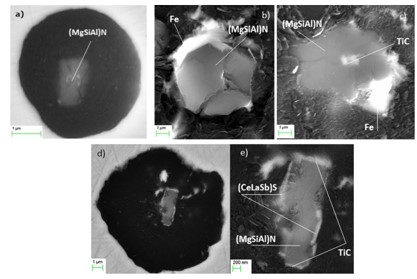

Graphite Spheroids – The Way they Grow

Graphite spheroids are one of the most intriguing forms of aggregation of graphite. They can be found as natural graphite

Graphite Spheroids – The Place where they are born

In the same way that a building needs a solid foundation to remain firm and stable, graphite requires proper nucleation

Do NDTs provide actual measurements of defects?

A common question that we usually receive at the Non-Destructive Testing area of AZTERLAN is whether conventional NDT provide real

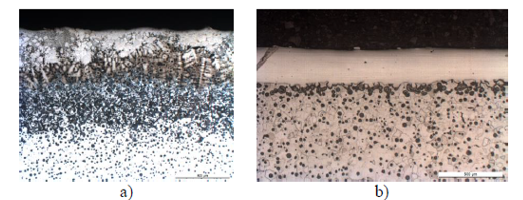

Metallic Powder Manufacture for Conditioning Cast Iron as an Additive Manufacturing Substrate

The main purpose of this work is to design and develop a metallic powder to use it as a paint

On the Role of Turbostratic Graphite in the Crystallization of Spheroidal Graphite During the Liquid-to-Solid Transformation

While turbostratic graphite is documented in many forms of graphite, there is a paucity of information on its contribution to

SUMA- Superior Materials (methodology)

New Materials SUMA Superior Materials Methodology for the development of new materials with advanced properties. More information Design and manufacture

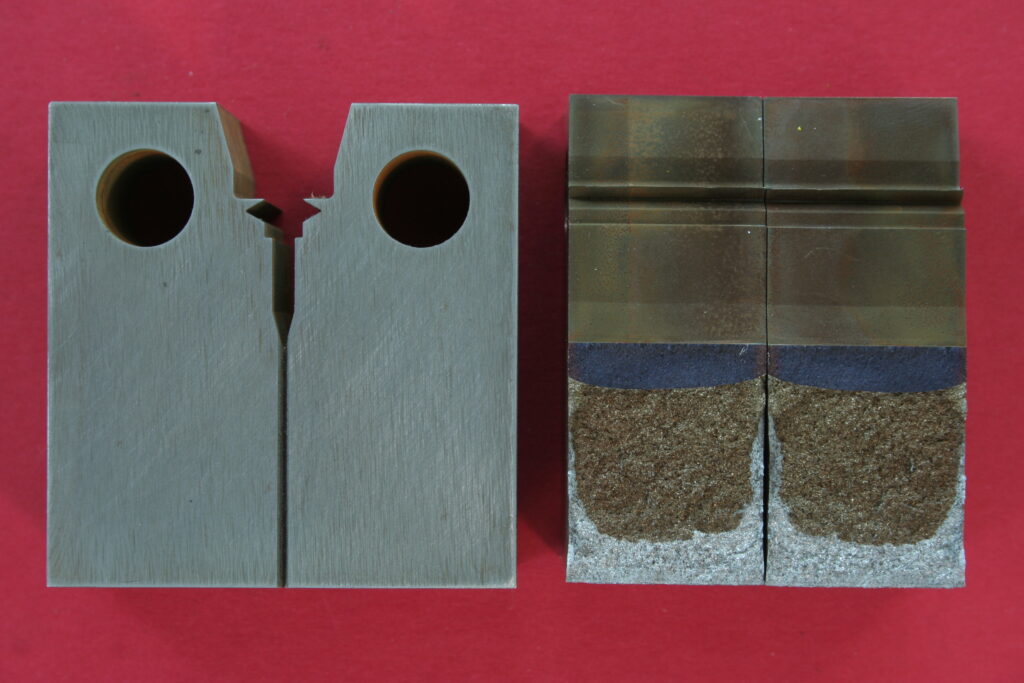

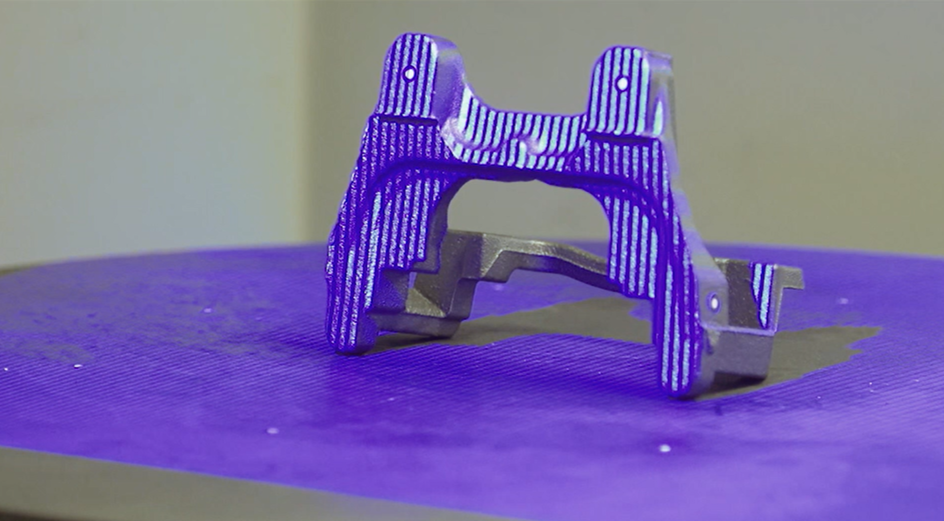

Iron castings with improved corrosion and wear resistance by means of LMD coatings

Iron Foundry Iron castings with improved corrosion and wear resistance by means of LMD coatings Patent protected invention More information

The mechanism of intermediate temperature embrittlement of cast irons by magnesium

Metallic alloys such as steels and nickel-based alloys are potentially vulnerable to high-temperature brittleness in the range of 500 °C

Kasandra®: Nucleation and solidification modelization of iron alloys for process control in real time

Nowadays, Foundry industries struggle to keep the competitiveness of their technology by means of more efficient processes. New technologies have allowed

SMART CASTING® – towards zero defect foundry

Manufacturing technologies SMART CASTING® Avoid finishing operations of low added value. Reduce operations, improve efficiency. Improve “lead time to market”

Method for producing a cast iron part with increased corrosion resistance and/or wear resistance, and the cast iron part obtained by said method

A method for producing a cast iron part comprising: a) obtaining a reactive paint comprising at least one first metallic