AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

New strategies for refilling single-layer stainless steel on nodular cast iron

Con objetivo de mejorar la resistencia al desgaste y a la corrosión en las piezas de fundición sin incrementar su

Improvement of the Metallurgical Quality of Ductile Iron in Heating Pouring Units through Appropriate inoculation

The metallurgical quality of ductile iron is strongly affected by the nucleation potential of the metal. Silicates, oxides, sulfides and

Effect of phosphorus on intermediate temperature embrittlement of high silicon

Spheroidal graphite cast irons can be susceptible to intermediate temperature embrittlement at temperatures between 350°C and 500°C. It has been

Influence of Severe Surface Plastic Deformation Induced by Shot Peening on Microstructure and Corrosion Resistance of fine grained 316 L stainless steel

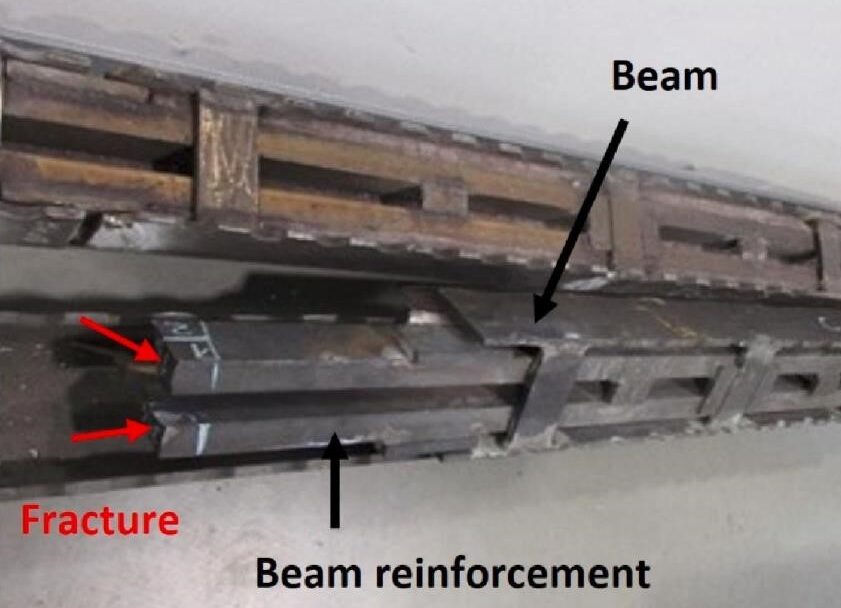

This work investigated the premature failure of a beam reinforcement made of austenitic stainless steel AISI 310 used in the

Failure analysis of an AISI 310 stainless steel beam reinforcement fracture during service in a rolling beam furnace

This work investigated the premature failure of a beam reinforcement made of austenitic stainless steel AISI 310 used in the

Influence of Niobium on the Microstructure of Gray Cast Iron

The final properties of grey cast iron depend on graphite morphology. Additions of certain trace elements can improve or degrade

Artificial Intelligence Based Foundry Process Optimization Technology

The arrival of Industry 4.0 has stimulated a significant increase in the digitalization of foundry plants, driven by the improved

SPT Study of Spheroidal Graphite Degeneration in Cast Iron Components

En la fundición nodular el contenido de Mg es uno de los principales parámetros a tener en cuenta. Gracias a

Prediction of the internal soundness of the castings directly on the production line. Importance of quality variations

The use of powerful computers has led to develop complex solidification simulation software that go beyond the use of Chorinov

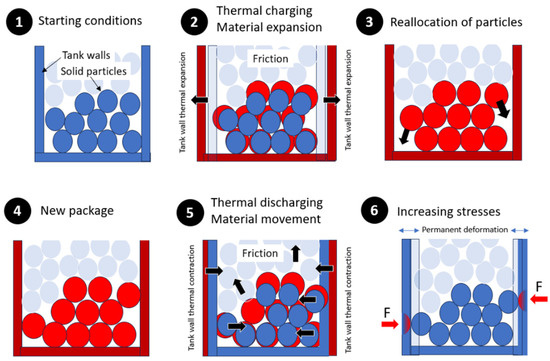

Characterization of the Ratcheting Effect on the Filler Material of a Steel Slag-Based Thermal Energy Storage

Thermocline thermal energy storage systems play a crucial role in enhancing energy efficiency in energy-intensive industries. Among available technologies, air-based

Study of the degeneration of spheroidal graphite in cast iron components by means of Small Punch Test (SPT)

In the present study, an investigation is carried out in which the morphological changes of graphite particles due to the

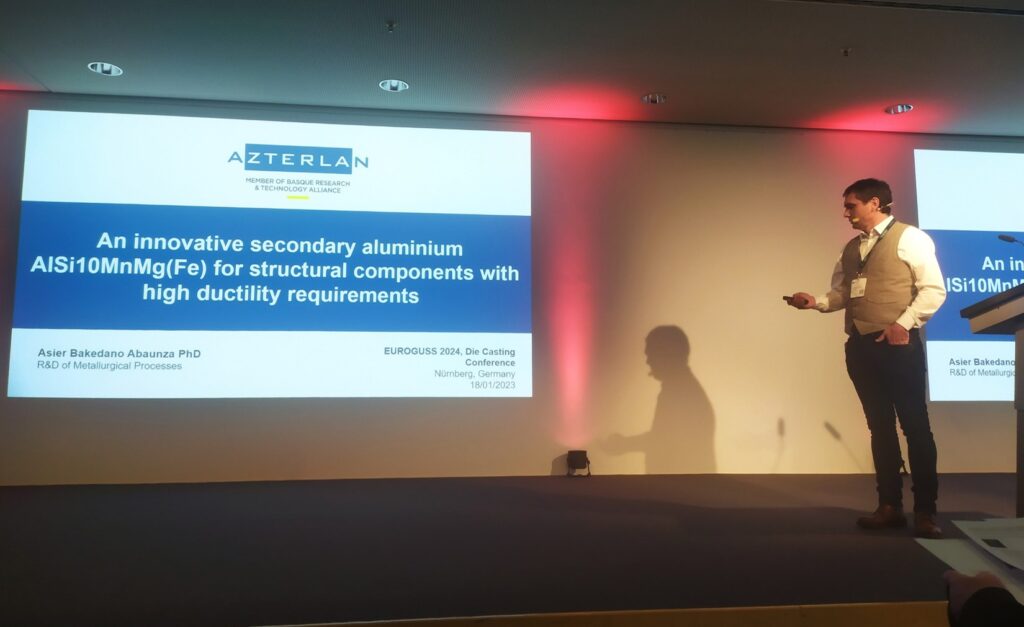

An innovative secondary aluminium AlSi10MnMg(Fe) for structural components with high ductility requirements

AlSi10MnMg primary aluminum alloy is widely used to manufacture structural components in the automotive market, such as front crash towers,

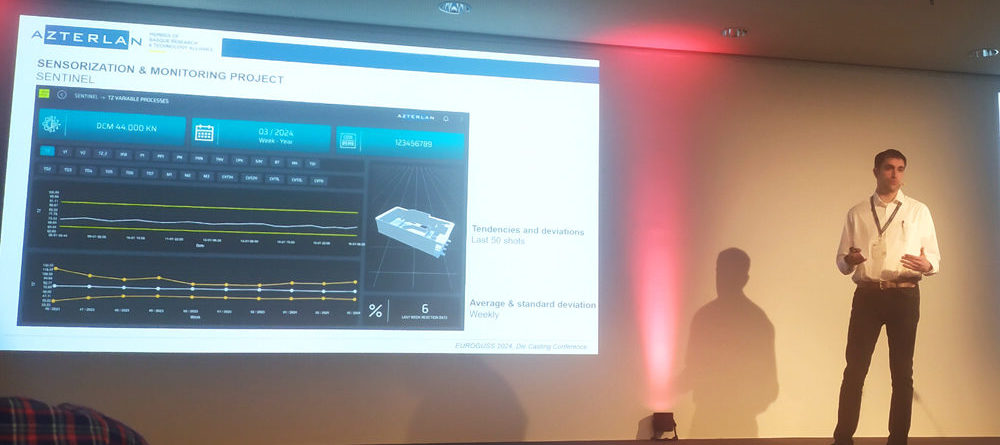

Industry 4.0 to optimize the HPDC process: how to monitorize and sensorize the HPDC cell

Undeniably, industry 4.0 revolution is reaching every industrial sector and the HPDC foundry could no be less. Gaining control over

Rethinking sustainability of metallic alloys

Advanced metallic materials are complex materials with very different compositions. As they are integrated into components, products and systems, their

Development of New Hybrid Composites for High-Temperature Applications

Nowadays, in the automation and aircraft industries, there is a challenge in minimizing the weight of components of vehicles without

Chemical Composition Effects on the Microstructure and Hot Hardness of NiCrSiFeB Self-Fluxing Alloys Manufactured via Gravity Casting

Ni-Cr-Si-Fe-B self-fluxing alloys are commonly used in hardfacing applications; in addition, they are subjected to conditions of wear, corrosion, and