AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

Understanding compacted graphite iron solidification through interrupted solidification experiments

While the manufacture of compacted graphite (CG) iron castings has seen significant expansion over the recent years, the growth of

New Furan no-bake binders to reduce the formaldehyde emission levels in the processes

The emissions of hazardous substances generated by the use of chemical binders represent today one of the most urgent challenges

Effect of Cu, Mn and Sn on pearlite growth kinetics in as-cast ductile irons

In a previously published work, pearlite growth in cast irons was investigated and it was claimed that growth kinetics of

AZTERLAN. A Metallurgy Research Center to support the industry

It is not easy to gather in a brief blog post the intense activity performed in the last year by

On the stable eutectic solidification of iron-carbon-silicon alloys

Extensive effort was expanded to elucidate the growth and morphology of the stable eutectic grains during early solidification of continuous

Microstructure of As-cast Ferritic-pearlitic Nodular Cast Irons

A review of past works on the formation of ferrite and pearlite in nodular cast iron is proposed. The effects

Influence of deep cryogenic treatment routes on the mechanical behaviour of a Cr-Mo-V hot work tool steel

Cryogenic treatments have shown a remarkable potential for improving the in-service performance of many tool steels despite the lack of

Efficient recycling of new generation aluminum alloys for the aviation industry.

The aviation industry is constantly evolving so that it can design lighter aircrafts, reduce consumption/emissions and put in place more

An innovative predictive system of metallurgical defect in iron castings, in real manufacturing time

En las empresas de fundición es habitual la utilización de herramientas de simulación numérica, con el fin de reducir el

Study of Strontium fading in Al-Si-Mg and Al-Si-Mg-Cu alloy by thermal analysis

The production of high quality parts for automotive and aircraft industries requires both improved melt processing and effective control tools

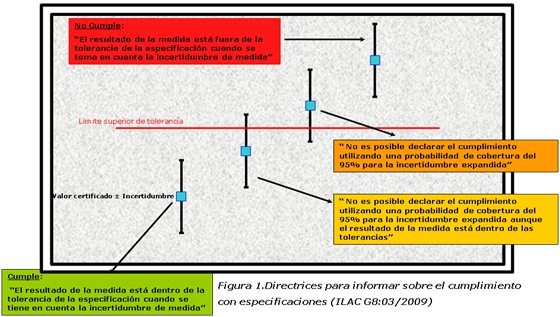

Testing uncertainty ratios: In what range of measures do we move?

When quantitative physical-chemical tests and analyses are performed, the concept of uncertainty is usually unnoticed, giving for fact that the

New As-Cast Ductile Iron Raises Bar for Properties

Ductile iron has a wide range of mechanical properties, depending on its metallic matrix. The material can replace cast and

Twinning Induced Plasticity steels (TWIP)

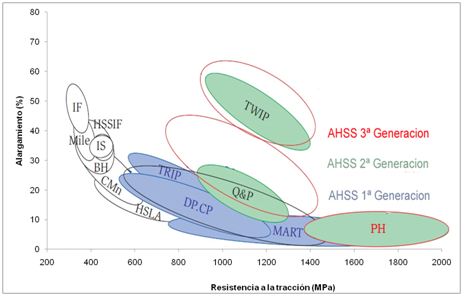

Advanced High Strength Steels (AHSS) are designed to provide an efficient answer to the actual demands from the automotive industry,

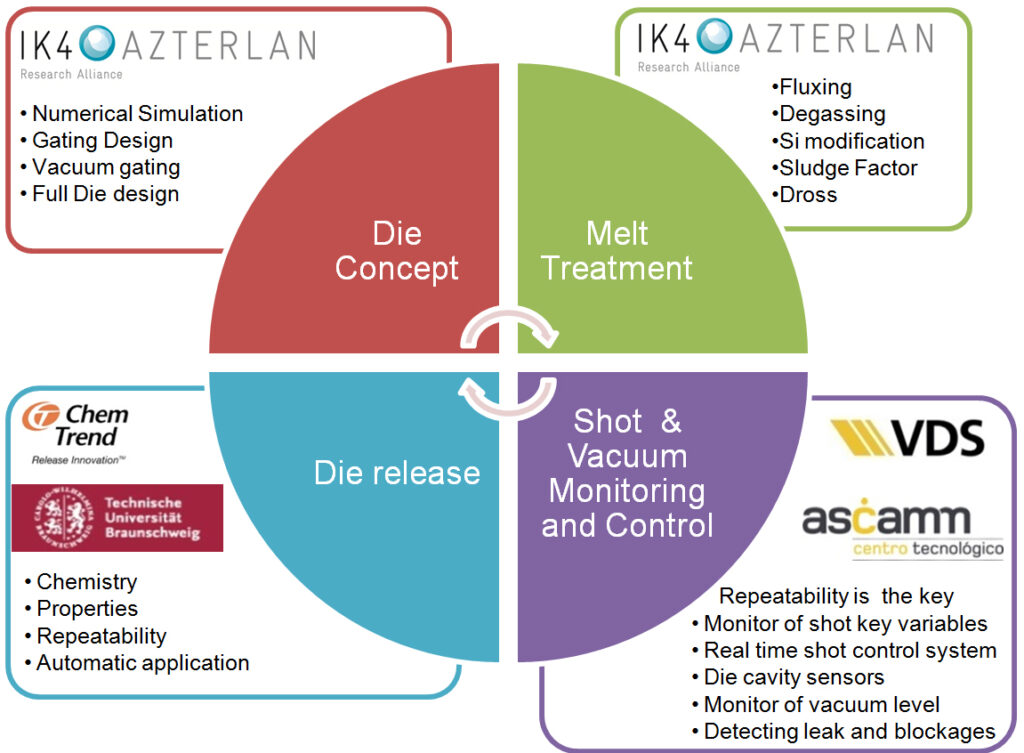

An Overview of Research Activities at IK4-Azterlan and Recent Technologies

IK4-Azterlan is a metallurgical research centre with broad experience in casting and solidification technologies for cast iron, steel and aluminium

Worldwide foundry industry exhibits its latest advances at GIFA

Once again, Düsseldorf has been the center of world foundry industry along the intense five working days of the last

Need for high integrity light weight structural castings

Global warming and resource shortage have lead to an urgent demand for reducing the weight of passenger´s vehicles. Since the