AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

Some paradoxical observations about spheroidal graphite degeneracy

Differential thermal analysis experiments have been performed on samples machined from Y2-blocks cast with different high-silicon spheroidal graphite irons. Depending

WFO WORLD FOUNDRY SUMMIT 2018 – Post Event Report

The World Foundry Organization (WFO) successfully held the first edition of the World Foundry Summit, on November 8th and 9th in

A reliable machining process by means of intensive use of modelling and process monitoring: approach 2025

This paper covers three significant aspects. Firstly, a global approach to manufacture high-added value components is presented. This process involves

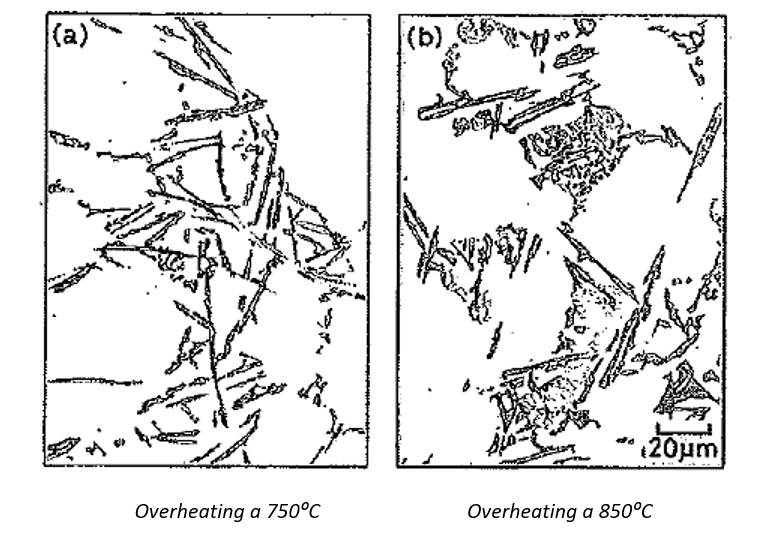

Cast components in super duplex alloys-intercomparison between bench moulding and 3D printing

This research work is focused on the application of sand moulds made with 3D printing technology to manufacture super duplex

Method for controlling active magnesium in ductile cast iron

The present invention relates to a method for controlling if the amount of active magnesium in a treated melt is

Development of new secondary alloys for the manufacture of ductile components by means of VHPDC technology

Optimization and implementation of Vacuum High Pressure Die Casting (VPDC or VHPDC) advanced technology is a relevant strategic research and development

Effect of Silicon and Graphite Degeneration on High-Temperature Oxidation of Ductile Cast Irons in Open Air

The use of high silicon ductile irons is increasing as they offer some advantages with respect to conventional pearlitic–ferritic grades

A Comparative Study of Graphite Growth in Cast Iron and in Analogous Systems

Crystallization of graphite during the solidification and cooling of cast iron to room temperature has been the object of relentless,

Rapid determination of nodularity index in ductile cast iron production

One of the most important facts in foundry industry when producing ductile iron castings is the rapid determination of the

The effect of the substitution of silicon by aluminium on the mechanical properties of gray iron

Gray iron, a Fe-C-Si alloy, is one of the most common ferrous alloys used in the metal casting industry. Silicon

Integration of a novel mechanical sand reclamation technology in a steel foundry to maximise SFS valorisation in foundry and construction applications

Spent Foundry Sand (SFS) generation is intrinsic to metal casting processes. Most of the foundries use sand moulds and cores

Solidification and Room Temperature Microstructure of a Fully Pearlitic Compacted Graphite Cast Iron

Compacted graphite cast irons are rapidly developing for they have better mechanical properties than lamellar graphite cast irons and present

Hydrogen Embrittlement Susceptibility of R4 and R5 High-Strenght Mooring Steels in Cold and Warm Seawater

Hydrogen embrittlement susceptibility ratios calculated from slow strain rate tensile tests have been employed to study the response of three

Retained Austenite Control for the Soft Machining of High-Hardness Tool Steels

Most high-hardness tool steels comprising forming dies require expensive finish machining operations to compensate for the dimensional distortion and surface

The Influence of Trace Elements on the Nature of the Nuclei of Graphite in Ductile Iron

Nucleation mechanisms and the effect of minor elements added with the inoculants are still a subject of extensive research in

Reassessment of Crystal Growth Theory of Graphite in Cast Iron

The problem of graphite crystallization and growth in cast iron has recently received increased attention. As most of the published