AZTERLAN

Knowledge Hub

Find out the technological developments, inventions, new materials and dissemination activities developed by the AZTERLAN team.

What are you looking for?

Developments and capabilities:

Dissemination:

Comparison of solidification kinetics of compacted and lamellar cast irons

Thermal analysis is largely used in cast-iron foundry shops as a means to check melt preparation before casting. It has

High wear resistant high entropy alloy and preparation thereof

The present invention discloses high entropy alloys that consist of the following composition, wherein the percentages are expressed by weight

A method to control ausferritic as-cast microstructure in ductile iron parts

A method to control the ausferritic as-cast microstructure in iron parts with sections of different thicknesses, which comprises: a) Calculate

Effect of the section size, holding temperature and time on the kinetics of the ausferritic transformation and mechanical properties of as-cast ausferritic ductile iron

The present research work studies the effect of section size, holding temperature and time on the microstructure and mechanical properties

Effects of cobalt on mechanical properties of high silicon ductile irons

High silicon ductile irons are being developed due to their advantages relating to pearlitic-ferritic grades (high ductility, fully ferritic structures,

A hybrid aluminium bronze alloy and its preparation method

The present invention is encompassed within the sector of metallurgical industry. Particularly, it relates to a new aluminium bronze alloy

Surface modification of ductile iron produced by an innovative in-situ casting technique

In this study, a chromium carbide layer was fabricated by an in-situ casting technique on ductile iron cast components. The

90 years of thermal analysis as a control tool in the melting of cast iron

Since its first literature mention in conjunction with cast iron in 1931 by Esser and Lautenbusch, thermal analysis (TA) has

Modelling of compacted graphite cast iron solidification-Discussion of microstructure parameters

A melt maintained for hours in a press pour unit allowed the following changes over time from spheroidal graphite to

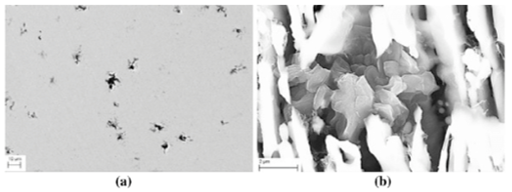

Effect of antimony on the nucleation process of spheroidal graphite iron

To further understand the influence of subversive elements on the nucleation process of spheroidal graphite, melts with antimony contents ranging

Reply to Comment on “Recent Developments in Understanding Nucleation and Crystallization of Spheroidal Graphite in Iron-Carbon-Silicon Alloys”

In their comments, Lacaze and Castro-Roman [1] seek to correct some statements that we made in our recent paper published

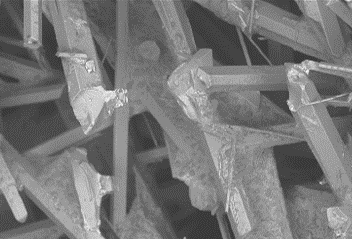

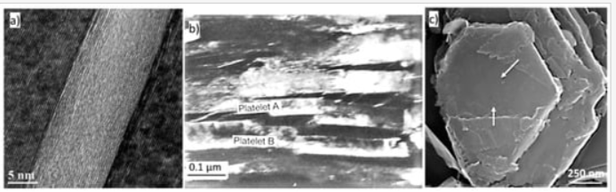

Graphite Nucleation in Compacted Graphite Cast Iron

During the last several decades, a multitude of theories have attempted to explain the process of graphite nucleation in lamellar

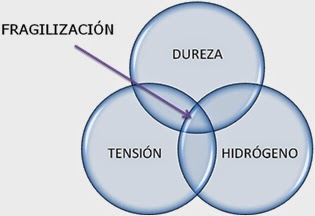

Hydrogen embrittlement

The identification of a failure of hydrogen embrittlement in a metallic component is often relatively simple in comparison with the

Method and device for obtaining and testing properties of sand casting mold

The present invention relates to a method for evaluating the mechanical properties of sand molds which comprises subjecting, at least

Recent Developments in Understanding Nucleation and Crystallization of Spheroidal Graphite in Iron-Carbon-Silicon Alloys

The last decade has witnessed significant research efforts directed to the understanding of nucleation and crystallization of graphite and associated

Quantitative analysis of the effect of inoculation and magnesium content on compacted graphite irons – Experimental approach

In many industrial domains, compact graphite cast irons are developing rapidly at the expense of lamellar graphite irons. The formation