A new sustainable material to develop the components of the future

Second-melt aluminum (secondary aluminum) has significant environmental and economic benefits compared to primary aluminum. This material is obtained from aluminum scrap after the useful life in service of components and structures has ended.

The main characteristic of secondary alloys is that they contain higher traces of impurities, which is why there is greater aprehension when incorporating them to the manufacture of certain structural components or parts subject to higher quality requirements.

AZTERLAN has developed new metallurgical knowledge, methodology and technologies to promote the definitive industrial approach fpr this promising sustainable material of the future.

Related contents

Main advantages

Recovery and revalorization of used aluminum

1) Assured mechanical properties

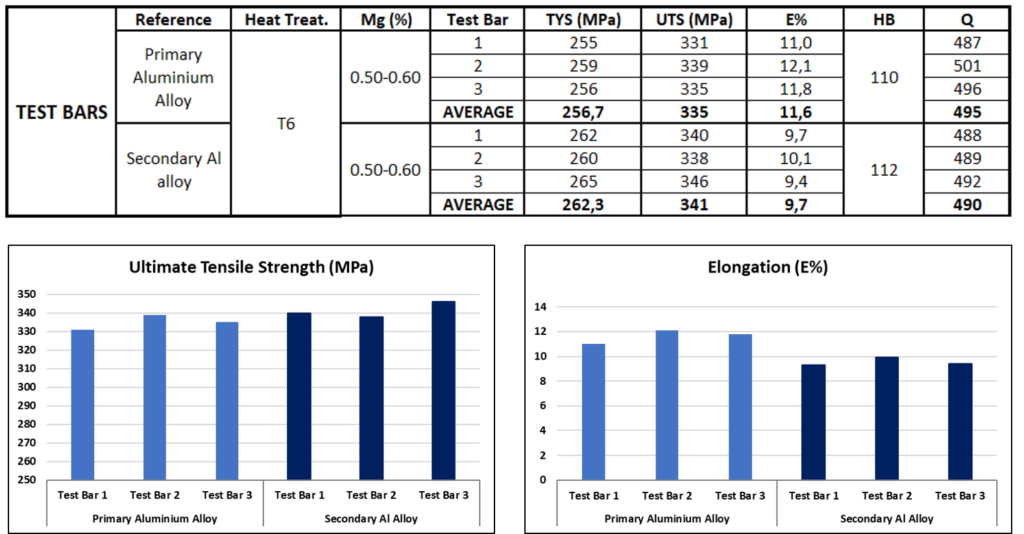

The methodology developed by AZTERLAN allows to ensure the mechanical properties of secondary aluminum to be used in the development of certain components.

The tables on the right show the properties presented by an alloy developed from recovered aluminum compared to those presented by a primary aluminum. The results obtained show positive properties of hardness and elasticity of secondary aluminum.

2) Avoid the extraction of new ore

While it is necessary to extract and treat 4.6 t of bauxite to obtain one tonne of pure (primary) aluminium, 98% of the aluminum scrap can be turned into reusable (secondary) aluminium.

The production process for the generation of primary aluminum also generates large amounts of slag.

3) Significant energy savings

The production of secondary aluminum requires only 5% of the energy needed to produce primary aluminum. While the generation of 1 ton of primary aluminum requires 17,000 kWh, the production of the same amount of secondary aluminum only requires 810 kWh.

4) Reduction of CO2 emmissions

Directly linked to the energy consumption of production process, while producing 1 kg of new aluminum generates 6.6 kg CO2e, the production of the same amount of secondary aluminum only generates 0.48 kg CO2e.

Lines of action

REcovery and revalorization of aluminum

New waste separation and classification strategies

A correct separation and classification of the recovered aluminum waste prior to its re-melting into ingots allows avoiding the downgrade of the materials as well as minimizing the addition of pure aluminum or the micro-alloying of specific elements.

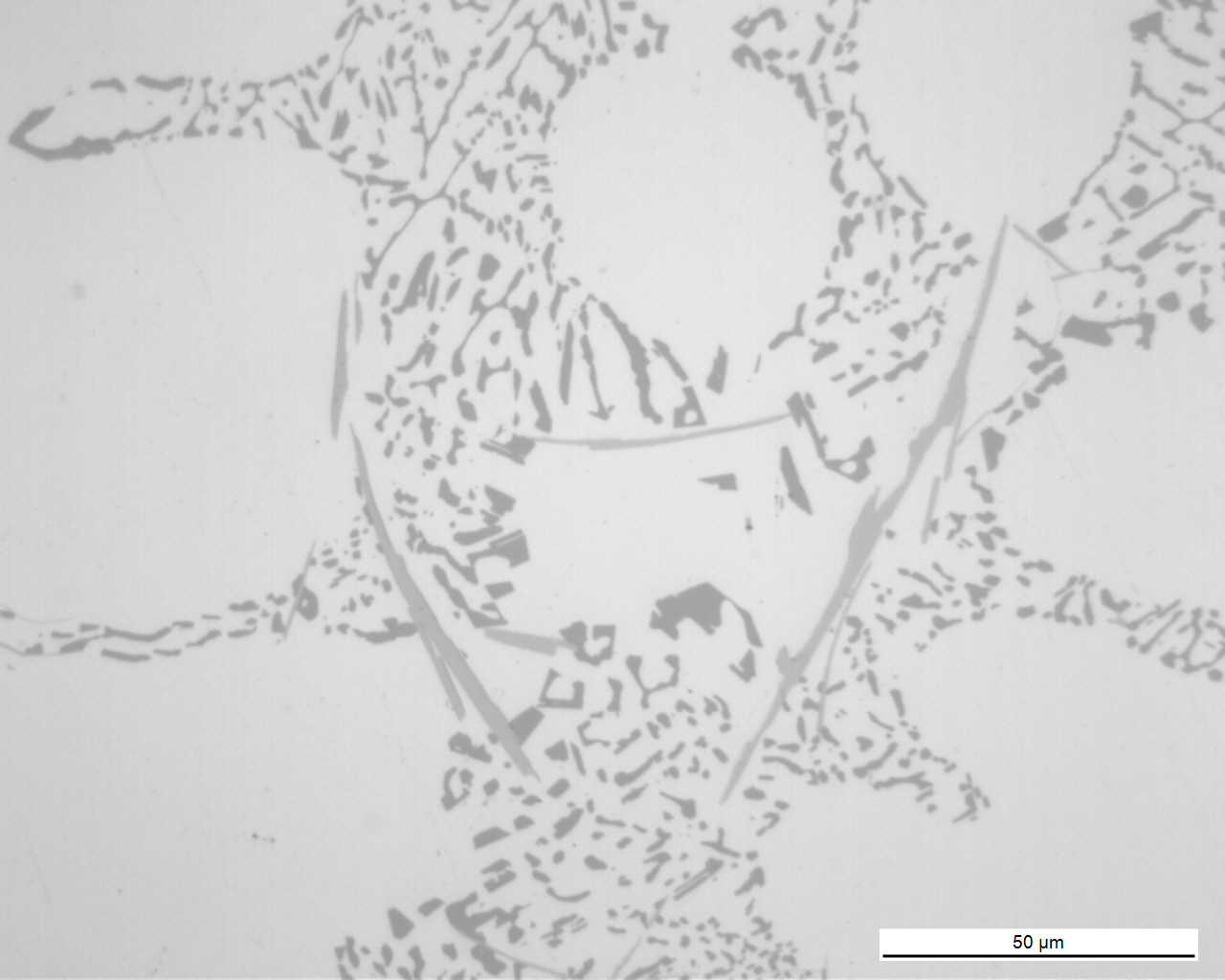

Innovative molten metal treatments

AZTERLAN has patented an innovative treatment for molten aluminum that includes: correct deoxidation and degassing of the casting, cleaning of the mold and the addition of salts.

This treatment of the metal in liquid state can also be combined with a physical filtering of the metal, as well as with alloys or microadditions of elements that counteract the harmful effects of certain levels of impurities.

Systems for assessing the quality of molten aluminum

Azterlan has developed equipment and tools to ensure the quality and the characteristics of aluminum alloys from liquid state:

Sustainable materials

Incorporate sustainable materials into the manufacture of your products with all the safety guarantees.

Re·Thinking Metallurgy

«Our work is aimed at mastering the physics and the chemistry that govern the behavior of metallic alloys, the phenomena that take place during manufacturing processes and the conditions that affect the useful life of metallic components.

We rethink metallurgy to develop more effective, efficient and sustainable manufacturing processes that favor the manufacture of components with enhanced properties and that open up new fields of application».