SALOMON – Multivariable process data analysis

Sistema de análisis multivariable para procesos de fabricación.

Inteligencia artificial y sistemas cognitivos aplicados al desarrollo de componentes metálicos.

-

Herramientas para la fabricación inteligente

-

Tags

Aitor Loizaga, Argoitz Zabala, Asier Bakedano, R&D+i, Susana Méndez

Using data to improve the knowledge and the control of the manufacturing process.

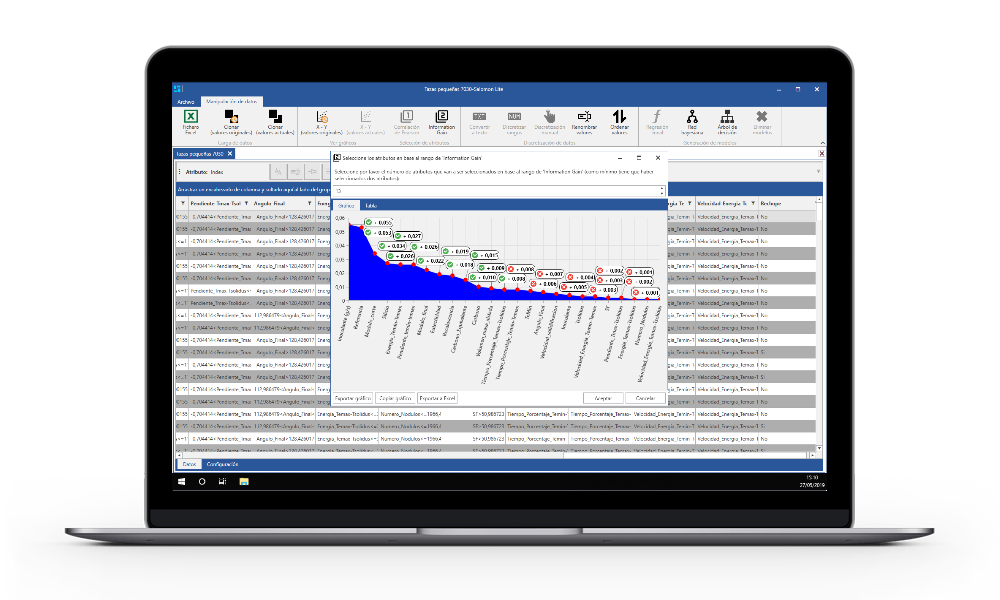

Salomon is the software developed by AZTERLAN to carry out an advanced and efficient multivariable analysis of the production process data available specifically shaped for the production of metallic components.

Using statistical techniques and algorithms based on Artificial Intelligence, Salomon simplifies “Data Analytics” through a totally defined, simple and clear methodology.

Advantages

Identification of the critical variables

Starting from the productive process data, Salomon makes it possible to determine which are the most influential variables regarding the issue under study, as well as their ranking of influence.

Interactions between variables

Determination of the multivariable cause-effect relationship between the various parameters and process variables when favoring or avoiding the appearance of defects or rejection.

Calculation of optimal parameters

Identification and calculation of the most appropriate manufacturing parameters to avoid unwanted results, working in the safest conditions for greater productivity and less rejection.

Target oriented analysis

New knowledge of high value to gain control over the production process to achieve more efficient processes and/or components and materials with specific properties.

System characteristics

This is how Salomon works

Get the best from your manufacturing data

Salomon software can be used with all metallic materials (aluminum, iron, steel) as well as their different manufacturing technologies (foundry, HPDC, LPDC, forging or stamping).

Mathematics at your fingertips

Most of the tasks performed with Salomon have a strong mathematical basis. However, its use does not require any mathematical background. Salomon simplifies the parameterization of mathematical methods based on scientific studies carried out by AZTERLAN. It allows applying statistical methods of correlation of variables, segmentation and manipulation of information and multivariate statistical classifiers, just within a few clicks.

Adjustment of variables that influence the result

Salomon can generate a series of models that, based on Artificial Intelligence techniques, can show the behavior of the metallurgical process. Selecting the states of each and every one of the variables, it can be observed how the selected target is modified by the influence of each of them. Similarly, Salomon allows to set a desired result state and observe how the rest of the variables should behave to get to it.

Complete goal-oriented analysis

Without the need for other tools, Salomon allows to treat the process data (modify, delete, group, generate, segment, etc.), validate the quality of the information, discretize and simplify the data, relate variables and discover their weight on the job goal. In the same way, Salomon also makes it possible to study the behavior of the process through the use of statistical models.

What do you need to use Salomon?

For the process manager

Salomon is an indispensable tool for understanding complex metallurgical processes in which many variables interact and for whose optimization it is important to analyze all the information that is produced on a dayly basis. The processes for which it has been developed and tested range from casting, forging, stamping, HPDC, LPDC and continuous casting, among others.

Starting poit: an Excel file

The only requirement to be able to use Salomon is to have a Microsoft Excel file that includes all the input data (process variables) and the output data (objectives to optimize). For this tool it is irrelevant which is the data source, that is, this file could be generated by an advance data capture system or just be fed by hand.

Data Analysis: Easy and simple

To work with Salomon no experience in Data Analysis is necessary. By following the simple and clear work methodology that has been defined, anyone can generate new knowledge and draw their own conclusions. So the criticality of the variables, their operation and interrelationships, as well as simulate what would happen when modifying the variables can be determined by any person using the system.