The increasing market demands in terms of cost and performance is continuously transforming the range of materials demanded by the industry, leading to the development of different solutions for each sector. These solutions can be often translated to improvement opportunities that can be shared from one sector to others. We will go through three representative examples that have been developed in the automotive, aerospace and heavy duty machinery applications that can be as well exported to other industries.

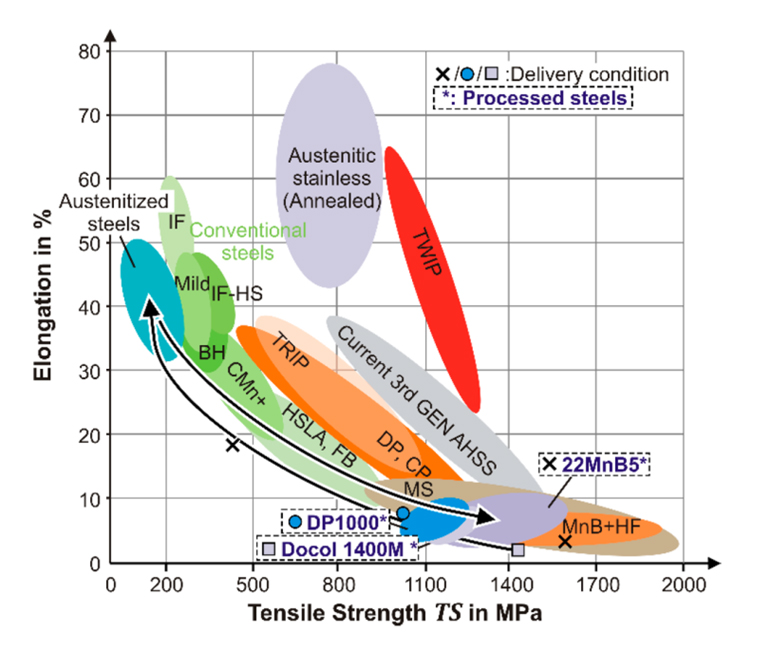

Press hardening, also known as hot stamping is used mainly to manufacture safety-related parts in the automotive industry. This advanced technology is based on hardening a new generation material, such as boron steel sheet. This innovative process allows forming advanced ultra high strength steel into complex shapes beyond the capabilities of traditional cold stamping. The crash tests have shown that safety characteristics can be significantly improved, reducing weight at the same time. In this context, press hardening is a hot sheet metal forming process that allows obtaining lightweight components with high complexity shape and high mechanical properties. It is defined as a “non-isothermal forming process for sheet metals, where forming and quenching take place in the same forming step” [1].

During the process, the steel blanks are heated up to the austenitization temperature of the steel, where it is malleable. This initial heating is followed by a forming and rapid cooling step, where the microstructure of the sheet metal is hardened by quenching, leading to a tensile strength of 1,500 MPa.

The ability to combine efficiently strength and geometrical complexity, allow press hardened parts to accomplish in one relatively light-weight component what would typically require thicker, heavier parts welded together in more than one process under cold stamping. In this contest, the hot stamping has become one of the most advanced lightweight solutions for the car body structure that simultaneously allows improving crash performance and passenger safety requirements. Press hardened steels have substituted over 40% of the weight in car Body-in-White structures and the same substitution process is expected in other transportation sectors.

Also aluminium is an excellent alternative to steel for reducing weight. Nowadays the aluminium alloys are the most widely used materials in aeronautic structures [3]. This fact is a major driving force for the development of lightweight aluminium solutions. Weight reduction is achieved by increasing shape complexity and mechanical strength of the aluminium alloys. The latest demands have been answered by developing special alloys, such as the new High Strength 6XXX alloys-HSA6 [4] or 7XXX alloys with Sc [5]. Although, the high strength of these alloys is an advantage for design, it becomes a drawback when strong deformation processes are required to shape the material. Processing limitations of these innovative materials require a significant effort to overcome the difficulties which arise during manufacturing of components. The combination of these technologies with high performance aluminium alloys (e.g. Sc reinforced Al alloys) offers the possibility to manufacture a higher strength material with a weight reduction of the final component.

Nowadays, there are many alloys used in the aviation industry and the most widely employed alloy is 7075. However, other innovative alloys such as the Al-Li alloy or the AL-Sc alloys are growing due to remarkable strength to weight ratio and their opportunities to increase design freedom at reduced weight.

The high aerospace requirements and their commitment to weight reduction to diminish CO2 emissions is the main driving force for new aluminium alloy developments. The aerospace industry continues to benefit from the new and traditional aluminium alloy’s properties in order to create safer, more reliable and less expensive aircrafts. This tendency clearly indicates that aluminium will continue being an important material for the aircraft industry. These developments have already started being transferred into the automotive sector and it seems to be a natural trend to increase aluminium in transportation.

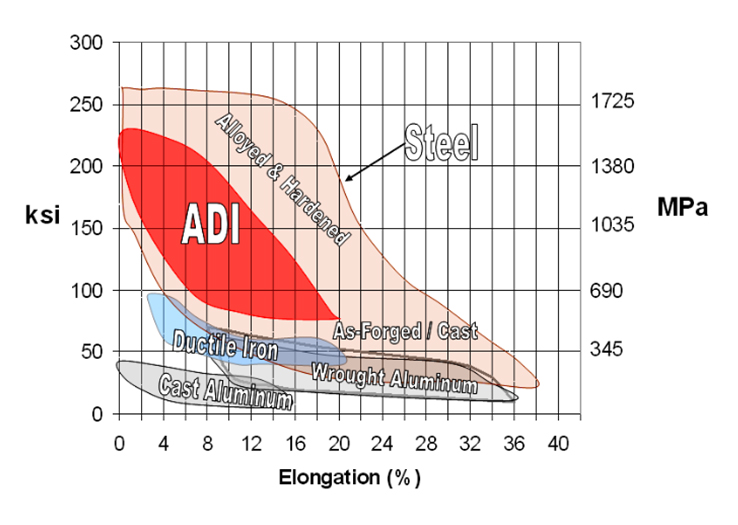

Advanced cast irons such as Austempered Ductile Iron (ADI), present an alternative solution for lightweight and materials efficiency. The ADI is a ferrous, cast material with a high strength-to-weight ratio and good dynamic properties. This makes ADI the choice when complex shapes are required as casting is a near-net-shape technology.