Iron Foundry

KASANDRA® – Software for a real-time prediction of the risk of defect apparition

Simulación predictiva para fundición de hierro.

Predicción de la aparición de defectos de contracción en fundición de hierro esferoidal, laminar y grafito compacto.

-

Cero defectos, 100% rendimiento.

-

Tags

Aitor Loizaga, Argoitz Zabala, Asier Bakedano, Iron foundry, José Manuel Gutiérrez, Kasandra, R&D+i, Susana Méndez, Thermolan

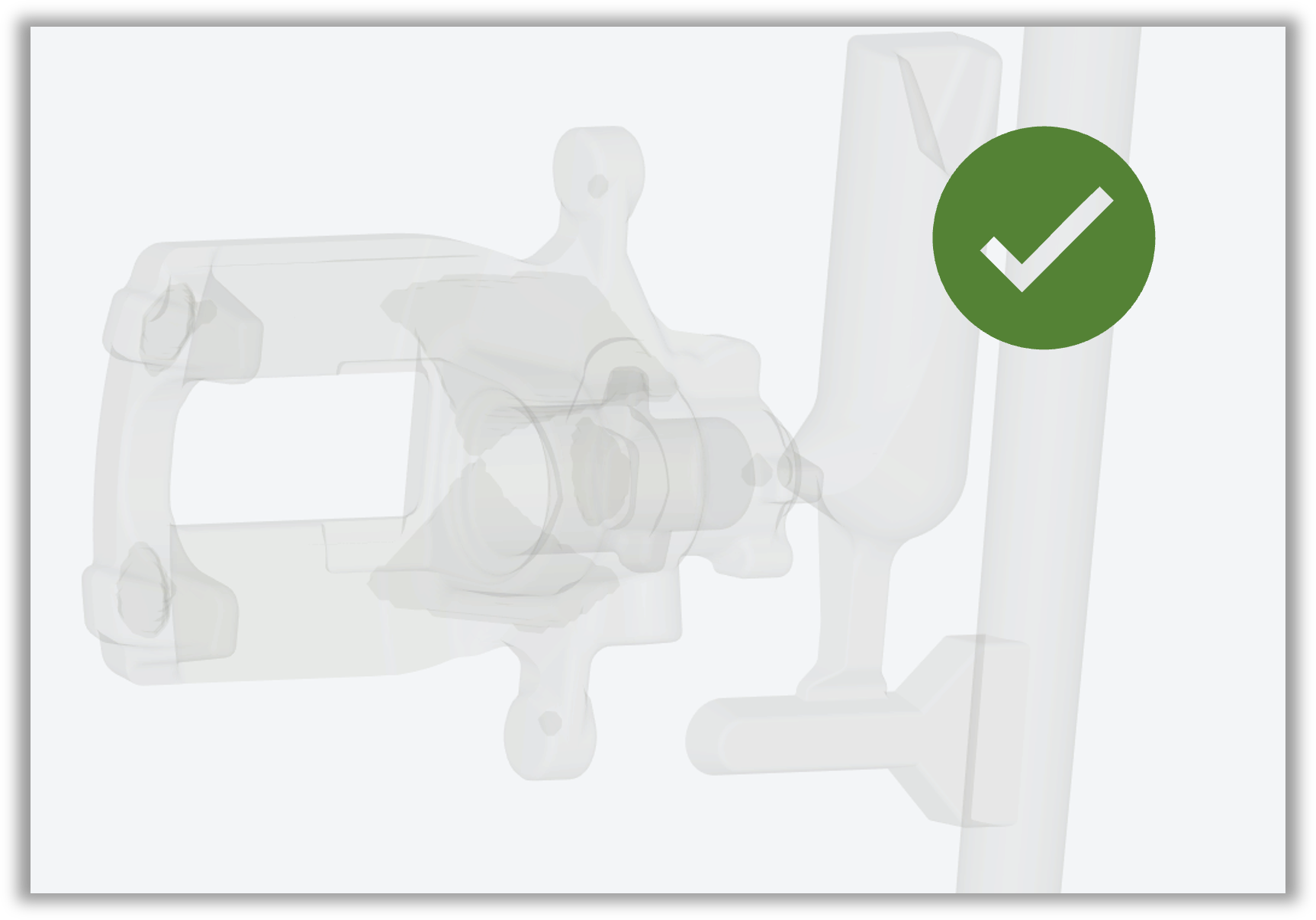

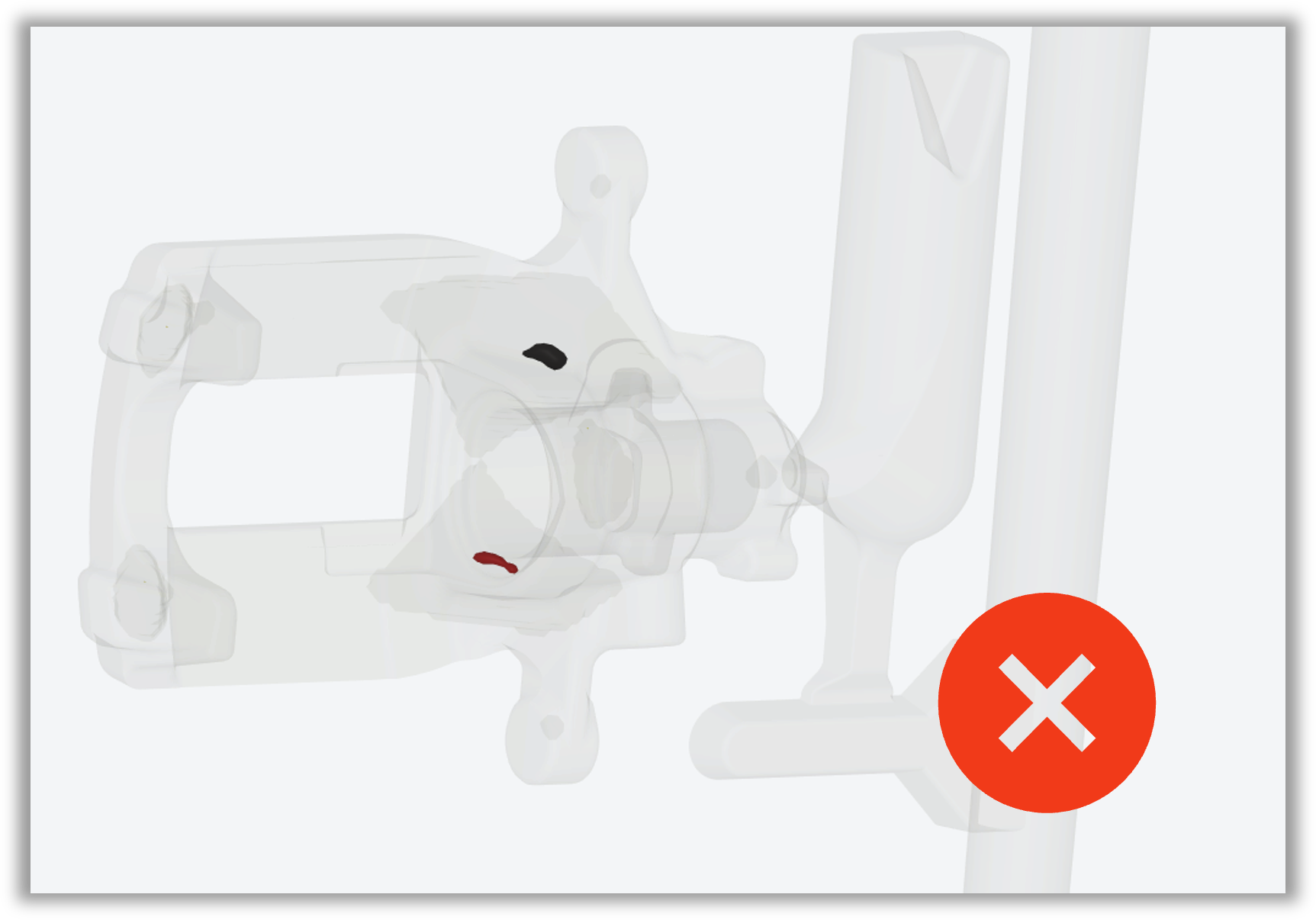

Avoid shrinkage and micro-shrinkage defects in your castings.

Kasandra® is the real time simulation software for spheroidal graphite foundry which, incorporating metallurgical quality (that is, thermal analysis and composition parameters) as a variable, provides a REAL TIME PREDICTION of the risk of apparition of contraction defects in critical zones of the components.

In order to perform the most reliable prediction, Kasandra® integrates the following data from the manufacturing process in actual time:

- Model geometry

- Filling process simulation

- Mold characteristics

- Feeding adjustment

- Isolated volumes analysis

- Metallurgical quaility of every casting

- Solidification process thermal risk

- Real time production process control

Related contents

Applications

Real time critical information

Know whether the quality of the melt will lead to defects apparition and their expected location. Adjust metallurgical features and feeding systems to ensure a quality outcome.

Unique features of every process

Exceed simulations based on standard parameters, incorporating the specific characteristics of your foundry and the quality of your melt.

Improve efficiency and yield

In real time, you will be able to implement corrective actions depending on the risk of critical defects aparition detected.

Ensure the quality of every batch and melt

Save costs and improve yield by optimizing the feeding capacity and the features of the melt.

Define the metallurgical needs of castings

During engineering phase, Kasandra engine is a powerful tool that outperforms other simulation tools by integrating metallurgical features for prediction and provides the keys to design and adjust metallurgical features and feeding systems:

- High yield designs and reduction in the number of risers applied.

- Considering graphite formation stages and composition needs.

- Reliable tool to perform feasibility studies and quotation (RFQ).

Know if the melt is suitable for manufacturing

In production process, Kasandra lite interface makes it possible to clear every melt, ladder by ladder, before being poured into the molds:

- In real time, determines the risk of metallurgical quality of the melt to provoke the apparition of defects in parts.

- Favors the implementation of corrective action by acting over the features of the metal, casting by casting.

- Reduces final inspections and controls.

Results exploitation

Understanding the most relevanta data

to assure a defect free production

Filling process simulation

- Detailed metal temperatures are obtained.

- The starting conditions for the solidification simulation are set by the temperature map obtained at the end of the filling process.

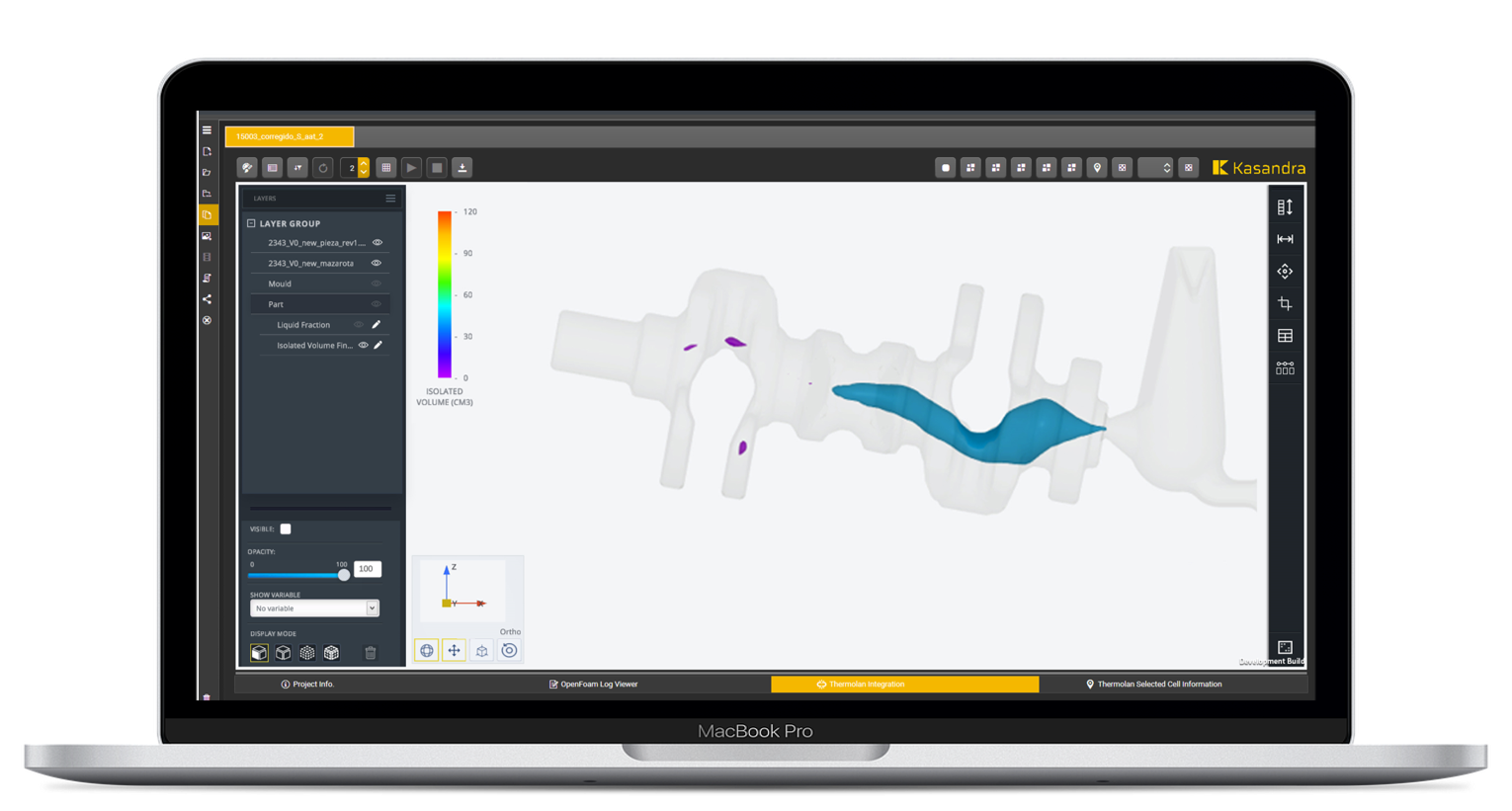

Solidification process simulation

Result of the solidification simulation for liquid fraction 0, such that the observed surface corresponds to a 99.9% solid metal and the internal fractions represent fractions in earlier transformation states or liquids.

This fraction conditions the primary feed from the riser and, therefore, determines the isolated volumes.

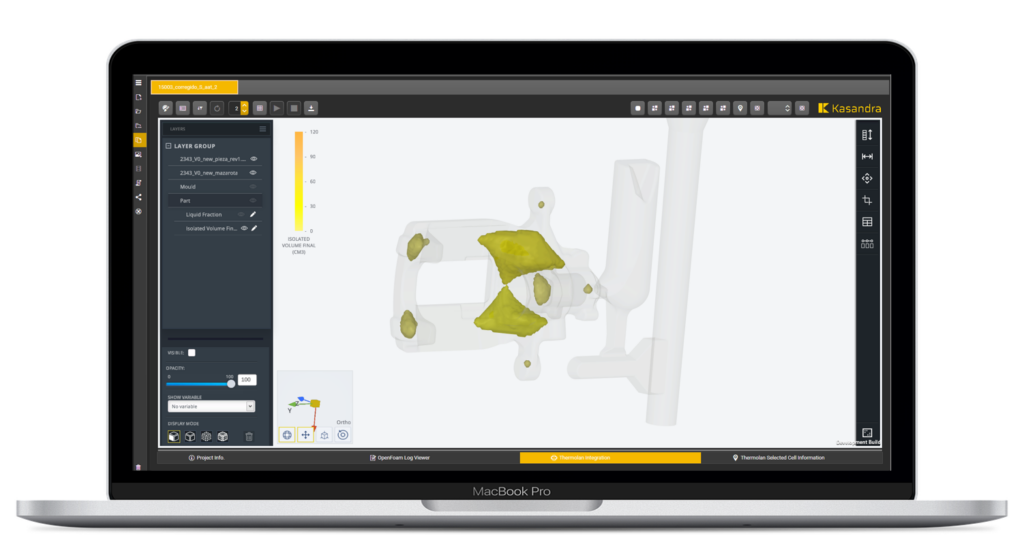

Isolated volumes representation

- The final isolated volumes represent the solidification process of the metal whose feed from the riser has been cut off and are, therefore, risk zones for the component’s soundness.

- Based on the thermal conditions (modulus, liquid fractions and hot spot) and the metallurgical quality, these isolated volumes represent the analysis units for the modelling of the contraction-expansion balance that ultimately allow the prediction of the appearance of defects.

Thermal modulus visualization

Thermal Modulus in internal areas of the part is visualized by layered cuts.

Thermal modulus analysis

Methodology for analyzing the thermal module in the hot spot of the part and the riser, to ensure correct feeding.

These study is essential to understand the risks of defects appearing in the neck of the riser.

Loading Thermal Analysis curves and porosity prediction

Thermal analysis curves can be loaded to get porosity prediction (the video shows an example for 3 metallurgical quality grades).

System features

Software

- Compatible with Windows.

- Different user interfaces adapted to use environments: Kasandra engine for engineering phase and Kasandra lite for production plant.

Current version of the software: v2

Yours is an older version? Reach our team

Hardware

To incorporate metallurgical quality into the fill simulation, Kasandra® needs to incorporate a thermal analysis system. Although the standard configuration of the system offered by AZTERLAN contemplates the application of Thermolan®, the Kasandra® system can be configured with other thermal analysis tools on the market.

Related solutions

Control your manufacturing process

Contact our team if you think that a smart management of your manufacturing process can improve your results.

Team

Shaping the

Foundry of the Future

“The Foundry of the Future is that of connected processes that is able to take advantage of the knowledge generated inside the company at the same time that it keeps learning from its manufacturing and market experience.

Along with a deep knowledge of metallurgy, Industry 4.0 technologies, advanced data management systems and machine learning technologies have landed in this industry to transform the way castings are conceived”.

xxxxx