The evaluation and determination of the grain size of steels is fundamental within the metallurgical characterization work since it can lead to the rejection of material for not complying with the requirements of the purchase specifications.

The importance of grain size is well known because it has a remarkable effect on the mechanical properties of the material. Fine-grained steels have greater tensile strength, greater ductility and become less distorted during quenching, being, in turn, less susceptible to cracking. In contrast, coarse-grained steels present opposite properties.

In any case, fine-grained structures are not always needed in steels, there are for example some applications in which it a rougher grain is preferable. These structures can reach a higher level of hardness, often desirable for carburization processes. Something similar happens with those steels that undergo cold work processes or in high temperature applications, improving their creep resistance.

The Diagnosis and Failure Analysis team of AZTERLAN has verified on many occasions that the deviation in the target grain size can have a direct relationship with the thermal process it has undergone, which may not have been propper, either due to a too high temperature or to an excessive furnace time.

Grain size characterization is a completely standardized process. The UNE EN ISO 643:2020 standards (internationally) and ASTM E-112:13 (at the USA) are the most widespread standards regarding product purchase specifications. Although the UNE EN ISO 643:2020 standard is only applied to steels, the ASTM E-112:13 standard is more generic, and it also includes non-metallic materials whose structures have similarities with the test pattern images defined for metallic structures.

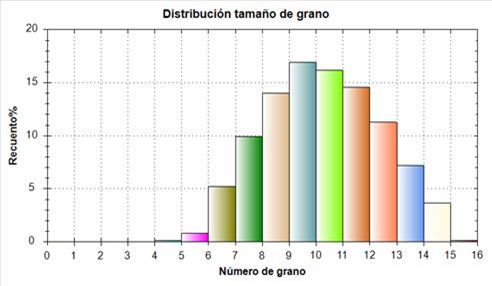

These standards include the methods of evaluation, the typology of steels that can be analysed, their corresponding methods of attack and the way in which the results are categorized and expressed. The grain size is cataloged according to the G index, the higher the G index the finer the grain size, and vice versa.

As a summary, the evaluation methods can be classified as follows:

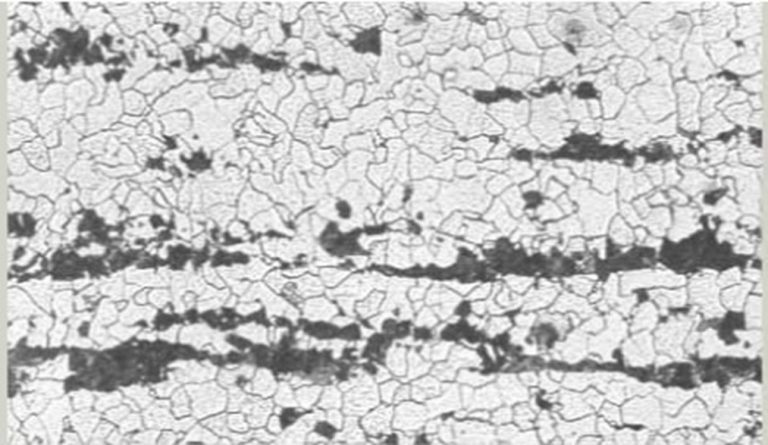

- Evaluation by comparison with referece images: The image examined is compared with a series of images defined in the ASTM E 112. The sample images are numbered from 00 to 10, so their number equals the G index.

- Planimetric method: By means of a circle or a rectangle, two countings are made. The first one sums up the grains completely contained within the area while the second counting sums up those grains intercepted by the circle or rectangle. By means of a series of equations, the G index is obtained.

- Intercepted segment method: It consists of counting the ammount of grain edges intercepted by means of a segment or circle. By means of a series of equations, the G index is obtained.

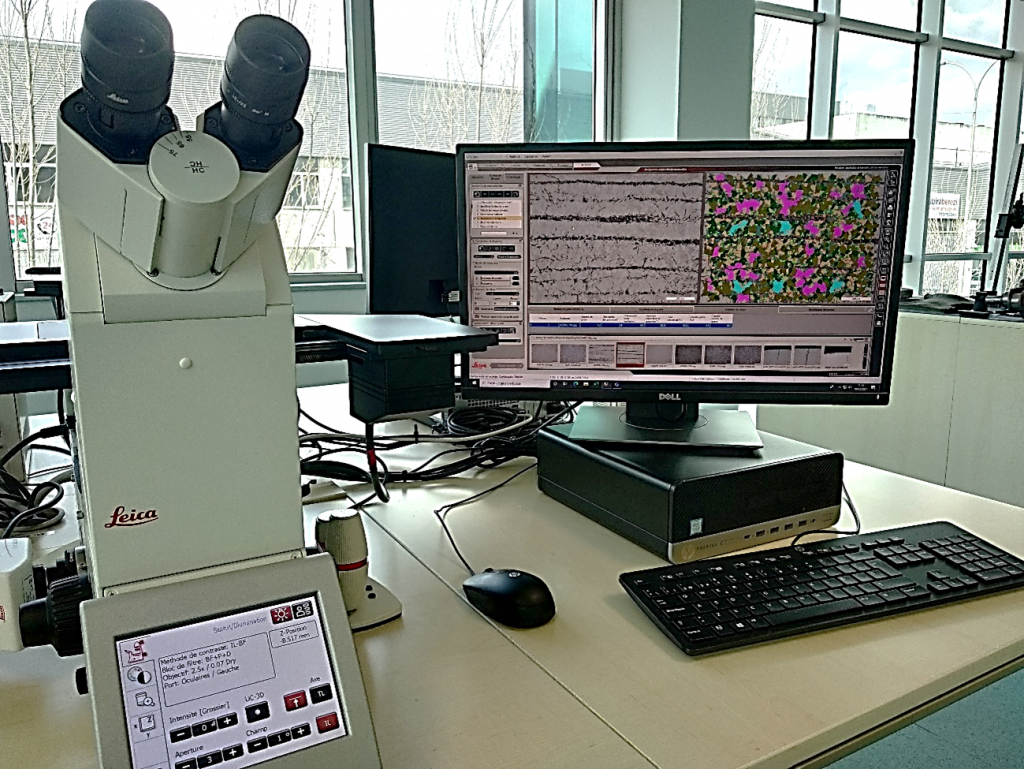

Grain size assessment software

Manual examination methods were, until not many years ago, the only way to determine the G index. However, nowadays advanced automated microscopy software can be found on the market. Among others, these softwares offer to metallurgical technicians and end customers some interesting functionalities such as:

- Automatic identification of grain edges.

- Adaptation to different types of grain.

- Elimination of the uncertainty inherent to manual analysis.

- Documentation and automatic generation of results.

All these characteristics provide a greater reliability of the results. The following advantages can be highlighted:

- Reproducibility, obtained through predefined processing settings along with automatic control of capture conditions.

- Compliance with the regulatory frame. Software follows the measuring procedures indicated by the standard, which can be selected along with the evaluation method.

- Improvement in the presentation of the results, through a statistical summary that is displayed in a tabular form, so the distribution of the shape of the individual grains can be displayed graphically as histograms, bars, or pie charts. This information provides added value to the results obtained, also providing the statistical distribution of the field evaluated.

However, given the wide variety of steel grades (and in their different heat treatment states), the use of these softwares is not exempt from the need for expert technical knowledge and from a rigorous interpretation and control by qualified personnel. In the case of AZTERLAN, the metallurgical knowledge and extensive experience of our team of accredited technical professionals makes it possible to get a high precision in the characterization and in the presentation of results, eliminating potential processing errors by means of the application of tools such as control prefilters and post-processing of threshold and sensitivity.

This way, the integration of the most advanced analysis technologies, combined with metallurgical rigor and technical knowledge specialization become the best guarantee for a correct and reliable metallurgical characterization.