-

Tags

The identification of a failure of hydrogen embrittlement in a metallic component is often relatively simple in comparison with the great significance that it implies.

When an analysis determines a high strength steel component, and after a short period of assembly some cracks are discovered on the part (failure mode known as “delayed fracture”), the range of possibilities is reduced dramatically to a single alternative. Then, it is only necessary to check that the fracture surface of the component has an intergranular character to confirm the preconceived hypothesis, and in most cases, to provide a comprehensive conclusion. Sometimes, it is very difficult for the analyst to consider any additional tests that could provide valuable information to corroborate and prove, without any doubt, the previous identification.

The argumentative simplicity of both “delayed fracture” alongside “intergranular texture”, contrasts with the serious consequences of this identification and which the analyst must be aware of.

When a manufacturer is informed about “hydrogen embrittlement” issues, it means that is being put into question not only the batch that is implied in the study but also the whole production process, i.e., the previous produced batches, the batches actually in production and future productions.

Due to the real challenge of analyzing the diffusible hydrogen in the material, is very complex to precise the origin of the hydrogen. Usually, it is necessary to work with non-verifiable assumptions. At the same time, this difficulty of measuring hydrogen makes it impossible to separate the identify batches and to prove the efficiency of the improvement introduced in the process to avoid the problem in future deliveries.

Thus, the simplest fact is to identify the failure type, but the real challenge lies in identifying the cause of hydrogenation; define a test to prove it and suggest preventive measures.

Great efforts have been made to understand the mechanism of embrittlement and even several theoretical models based on internal pressure, surface energy, weak links etc, have been raised, although, there is currently no largely accepted theory by the scientific community.

Without considering these theoretical aspects, there are several well-known indentified circumstances of such failures that should always be taken into consideration:

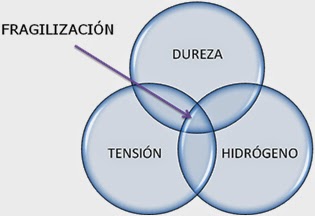

1. Hydrogen embrittlement failures are due to a combination of factors. For this reason, in a batch of “identical” components, installed in “identical” conditions, the failures do not affect the entire production, but a certain number of components. The failure rate reflects the criticality of the problem. Experience shows that it is not advisable to focus on why the rest of the elements exposed to identical conditions have not cracked. A single fracture with the right features can be considered representative enough to compromise the whole batch. In fact, there are standardized procedures to analyze the occurrence of this embrittlement phenomenon which are precisely based on parts study in which a single cracked element means the rejection of the entire batch.

2. To reveal hydrogen embrittlement, the component must be under tension. The higher the tension the greater is its susceptibility to this problem. It is not possible to demonstrate the embrittlement of a material by conventional mechanical tests (hardness, tensile and impact test, etc.); specific tests under appropriate conditions are required.

3. The hydrogen embrittlement affects mainly high strength materials. The hardness of the material reflects the susceptibility to this type of phenomenon. In fact, an effective preventive measure to mitigate its effect, is to reduce the hardness of the material to a minimum within the accepted range.

4. A known origin of hydrogen is the acid pickling (descaling) prior to the application of the coating, but there are many other possibilities, including the residual hydrogen value in the raw material. There is not a limit value of hydrogen to generate this problem which is valid for all components. This critical value is influenced by the composition of the material, the hardness level and the tension applied to the component.

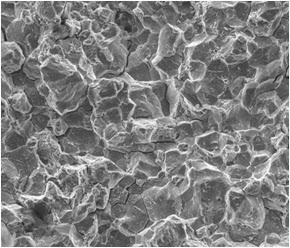

5. The fracture plane of an element that has failed due to hydrogen embrittlement is always perpendicular to the stress that stands the component in that location. The fracture surface in steels is characterized by its intergranular texture. There are other types of hydrogen damage, but the embrittlement phenomenon is always mainly intergranular or at least it shows some granular character, mixed with branched forms.

| Intergranular character, typical of these kinds of failures |

| The failures provoked by hydrogen embrittlement are the result of a combination of several factors |