HIPERMAT. Advanced design, monitoring, development and validation of novel HIgh PERformance MATerials and components

-

Tags

Finished project

Start date

European Union

Funding

958196

grant agreement number

End date

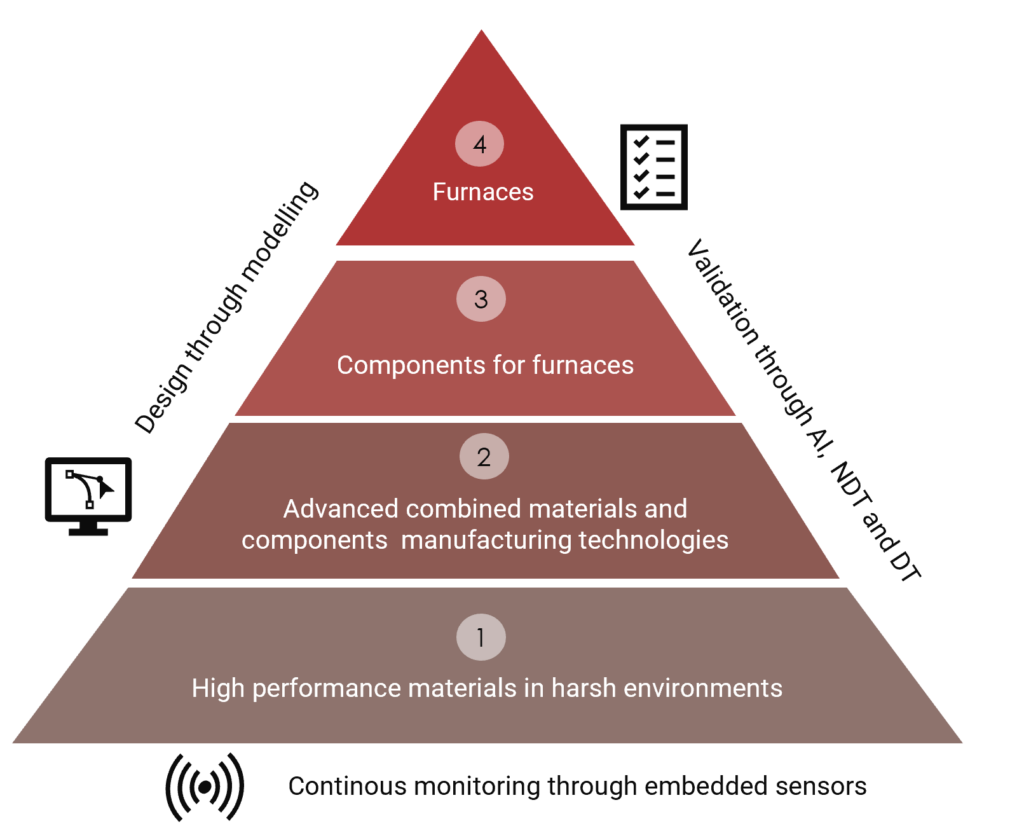

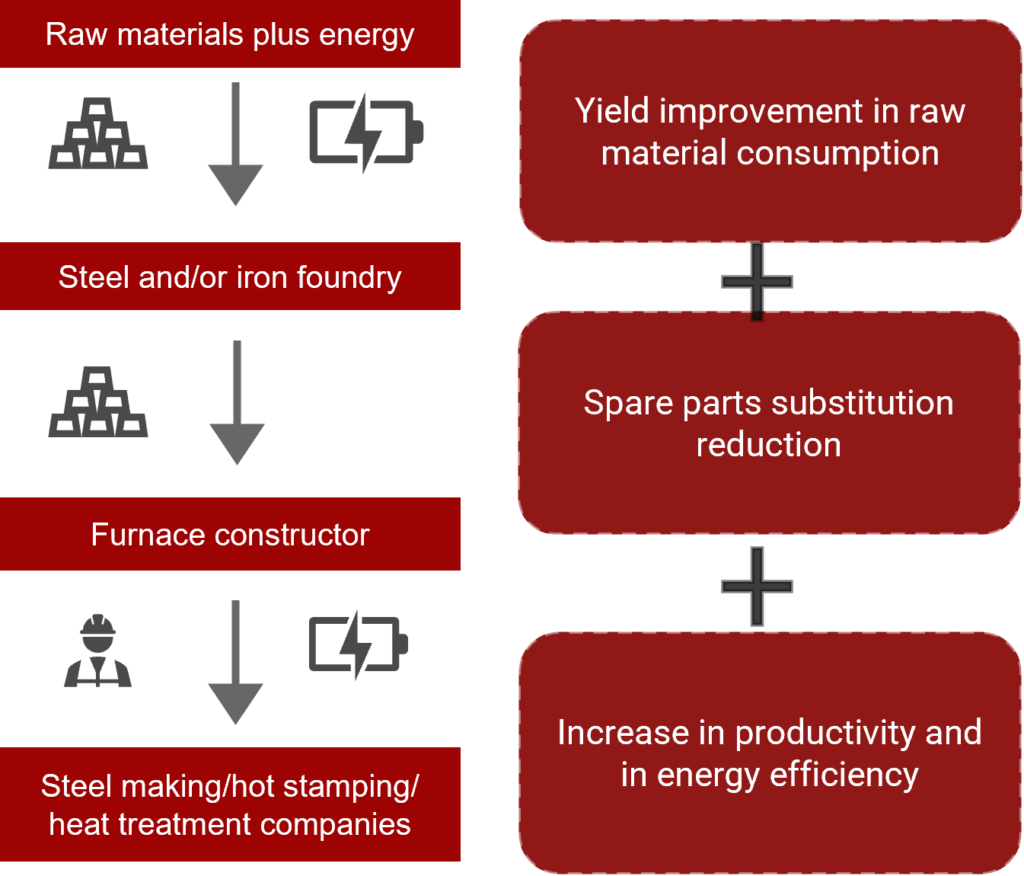

HIPERMAT’s main objective is to promote the low-emission technologies of the future by improving the environmental impact of materials and components throughout its value chain.

Within the project, at least two refractory stainless steels and a ceramic coating will be created through advanced modeling, hydrosolidification, LMD and innovative technologies for applying ceramic coatings to beams and rings of hot stamping ovens with embedded sensors.

Developing components that are more resistant to thermal fatigue, creep and corrosion.

Related contents

Main goals of HiperMAT

- Optimization of industrial processing by optimizing component manufacturing process: reducing use of energy and raw materials and increasing the efficiency of the plant thanks to less plant shutdowns for maintenance and spare parts purposes.

- Reduction of the energy and resource consumption by more efficient technologies to manufacture components and their life extension in high temperature close to 1000ºC working equipment.

- Minimization of waste and energy consumption by using sustainable processing technologies. Integrating cutting-edge and more accurate modeling tools into the design of processes and materials.

- Introduction of protective layers in components reducing critical elements in bulk materials and extending their service life.

Approach

Main outcomes

HIPERMAT project ended up a significant number of technical and industrial results that can pave the way for the introduction of new technologies and materials in high temperature applications. The use of these results initially focused on the hot stamping sector has a high potential of extending their application to the process industry and energy generation sectors:

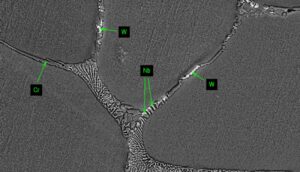

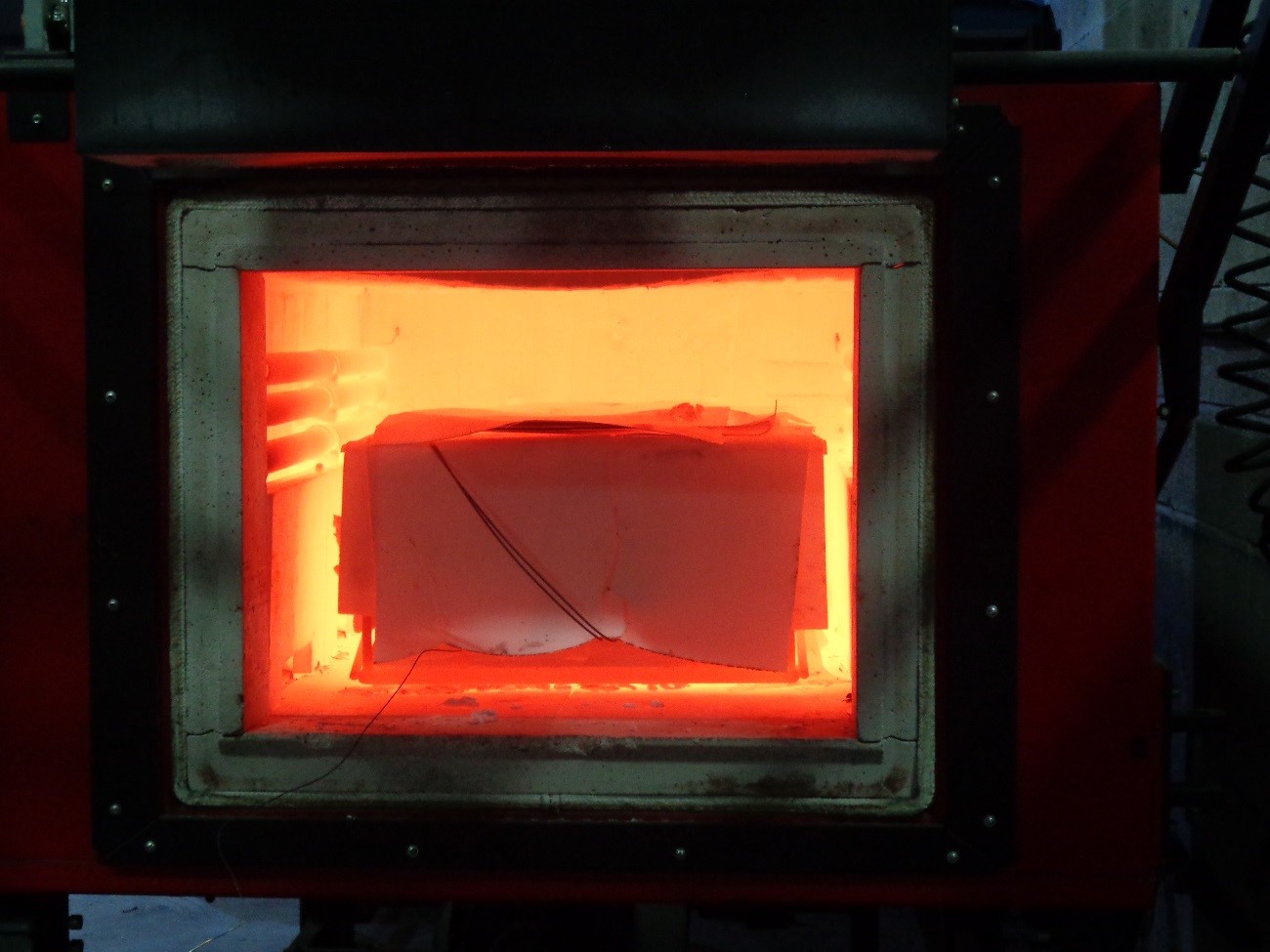

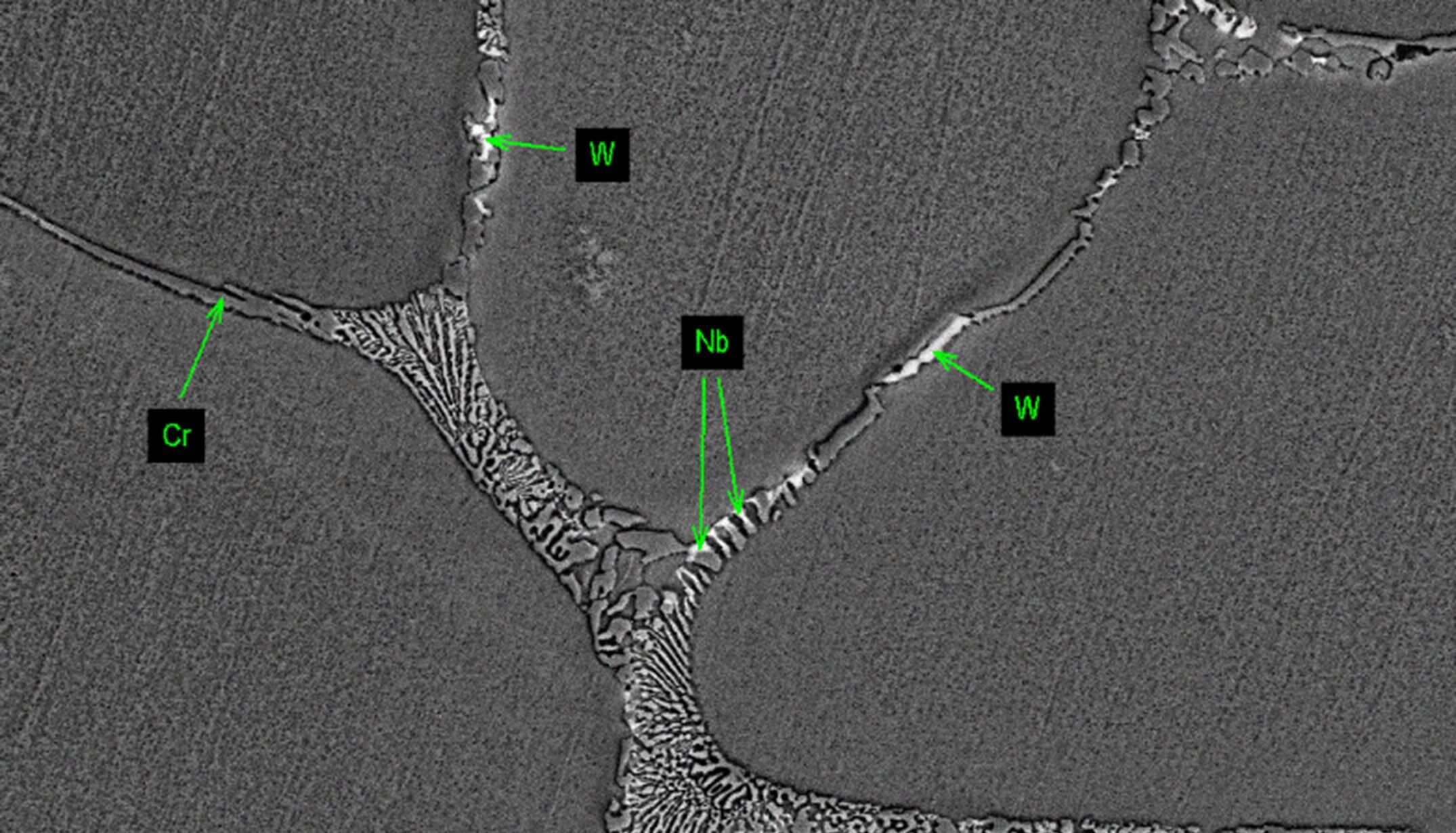

- A refractory stainless steel for beams manufacturing with superior properties in terms of creep and wear compared with current alloy in use (REF) identified as BEEN1 has been validated, from lab condition to component like geometries manufacturing to a prototype beam manufacturing and is inside the furnace been tested. The behaviour of this alloy shows significant improvements compared to REF alloy. AZTERLAN METALLURGY RESEARCH CENTRE.

- A refractory stainless steel with high wear and creep resistance identified as alloy R, has been validated from lab condition to component like geometries to prototype rings integrated in one roller and introduced in one hot stamping furnace. The results show a significant improvement in creep and wear resistance compared with the alloy currently in use. AZTERLAN METALLURGY RESEARCH CENTRE.

- Printed sensors for high temperature applications have been validated at lab scale with good coherency with traditional wire based types. ADVANCE COATING & CONSTRUCTION SOLUTIONS (AC&CS).

- A Haynes 230 superalloy has been applied by LMD initially at lab level, later in component like geometries and finally in one ring that is currently running inside a hot stamping furnace. Wear test at lab level have shown a significant wear improvement in its performance compared with the current alloy in use. ASOCIACION CENTRO TECNOLOGICO CEIT.

- A new CERMET coating has been applied and validated initially at lab level, later at component like geometry and finally in one ring that is currently running inside a hot stamping furnace. Wear test at lab level have shown a significant wear improvement in its performance compared with the current alloy in use. FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG E.V.

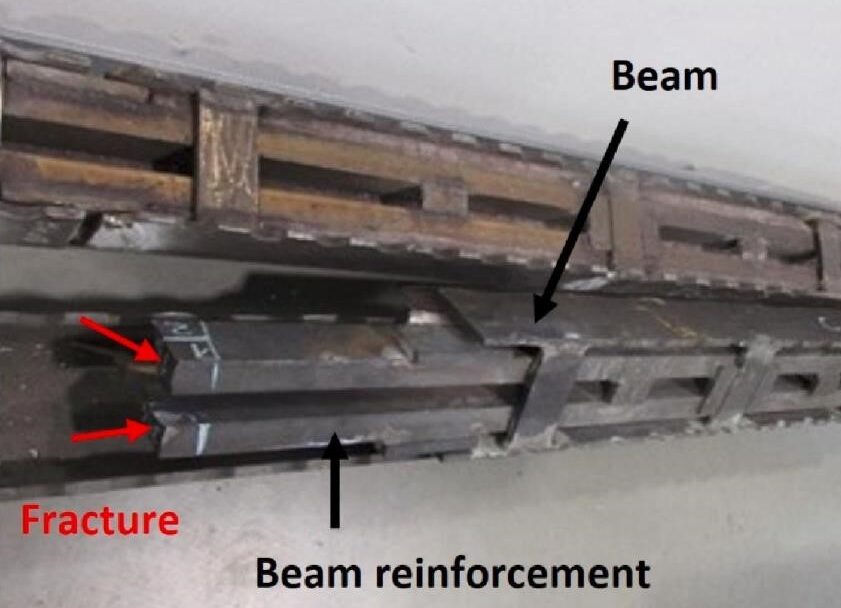

- The HydroSolidification process has been performed initially for samples at lab scale and later for component like geometries represented by the portion of a beam. The results have shown a significant creep and creep crack growth rate improvement compared with a current alloy. One portion of the beam has been introduced into a hot stamping furnace to analyse its evolution. AZTERLAN METALLURGY RESEARCH CENTRE.

- A combined material and process strategy has been followed in the case of LMD application combining material parameters and process parameters, to tests solutions for cracks reduction in the application of layers, the modelling has shown good coherency between predictions and results. ESI SOFTWARE GERMANY GMBH (ESI).

- The set of data regarding creep and their link with microstructure have been used for material database completion for the prediction of this parameter. QUESTEK EUROPE AB.

- Embedded sensors have been integrated in one ceramic beam inside the furnace and their behaviour has been monitored. The accuracy in measuring has been good, however connections have not been robust enough and have failed after a intermediate period of time. Further research is needed to upscale the solution. ADVANCE COATING & CONSTRUCTION SOLUTIONS (AC&CS).

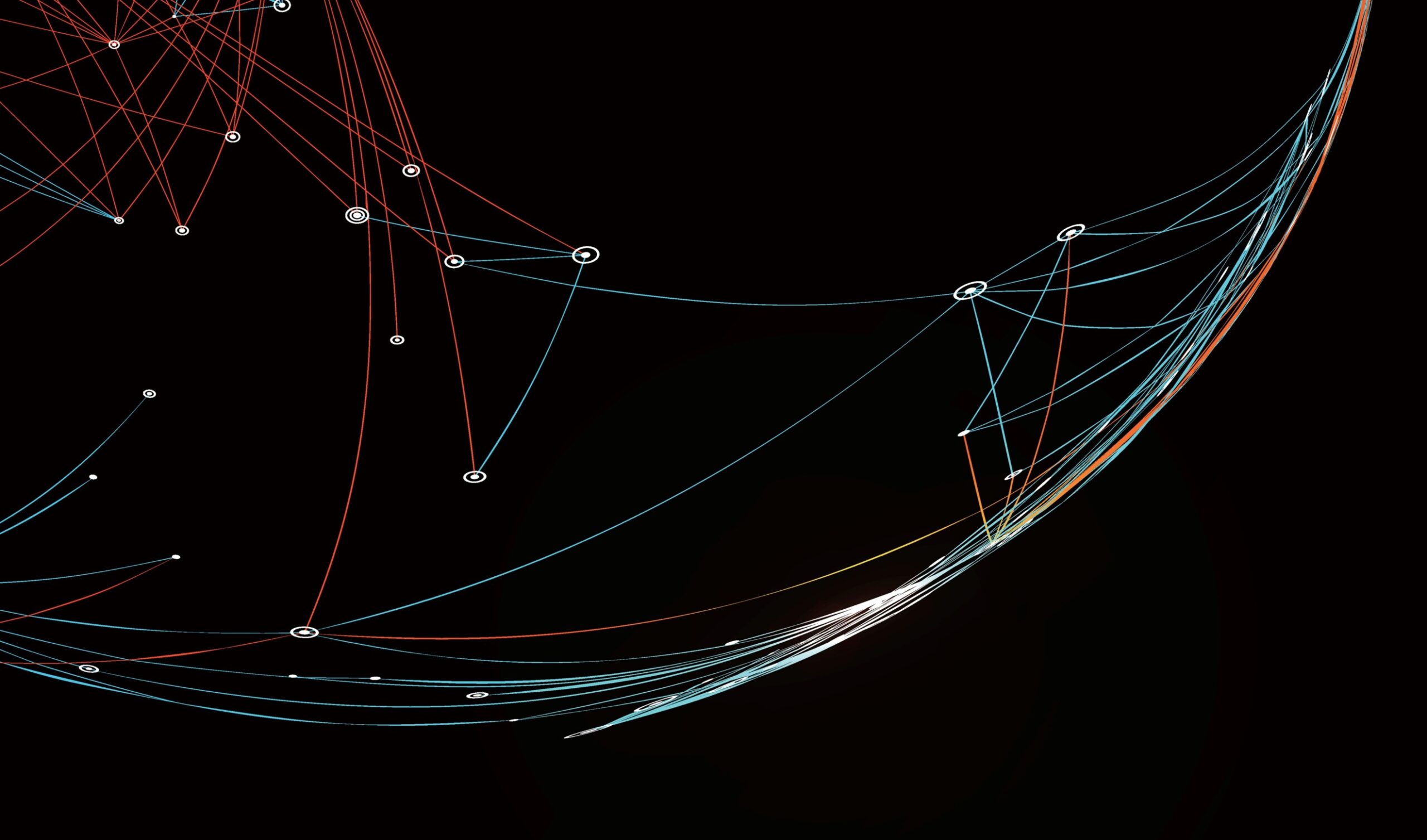

- A data analytics software has been used to determine main critical aspects in terms of bulk material development to achieve improved values of high temperature resistance. Results are coherent with obtained lab tests and remains as a tool for future fine tunning of developed alloys. AZTERLAN METALLURGY RESEARCH CENTRE.

- Software has been adapted to each type of alloy and process under study incorporating or removing different variables depending on the case AZTERLAN METALLURGY RESEARCH CENTRE.

- A prototype beam has been manufactured using the industrial facilities using the developed alloy BEEN1. The beam is inside a hot stamping furnace to follow up its behaviour during a year period. AMPO S. COOP.

- Prototype rings in the form of bulk materials (R alloy), Haynes 230 layer applied by LMD and ceramic coating applied by HVOF has been introduced in rollers and inside the hot stamping furnace. AMPO S. COOP.

- A current running furnace is testing the prototype beams and rings. GHI HORNOS INDUSTRIALES, SL (GHI).

- Data captured inside the furnace through embedded sensors shows differences with sensors located in furnace walls presenting significant opportunities for better monitoring of temperature of steel blanks that need to be processed. FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG E.V.

- Opportunities for new alloys development can be found in deep knowledge of main aspects affecting materials creep performance, available for teaching and service providing. KUNGLIGA TEKNISKA HOEGSKOLAN (KTH).

Project consortium

AZTERLAN, GHI HORNOS INDUSTRIALES, KUNGLIGA TEKNISKA HOEGSKOLAN, QuesTek Europe AB, ESI SOFTWARE GERMANY GMBH, SVUM AS, AMPO S. Coop., FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG E.V., FUNDACIO EURECAT, ASOCIACION CENTRO TECNOLOGICO CEIT, RINA CONSULTING – CENTRO SVILUPPO MATERIALI SPA, ADVANCED COATINGS & CONSTRUCTION SOLUTIONS, GESTAMP LOUNY SRO Czech Republic, Calcom ESI.

Activity and resources

News

Other resources

Development of high performance materials and processes for applications under extreme energy conditions

Failure analysis of an AISI 310 stainless steel beam reinforcement fracture during service in a rolling beam furnace

New high temperature resistant material for building hot-stamping rolling beam furnaces

HTSTEELS – Super-refractory stainless steels

SUMA- Superior Materials (methodology)

High Performance Materials for extreme Energy Intensive Industry Process Environments

High creep resistant refractory stainless steels (super-refractories)

Workshop: “Novel high performance materials and components”

New scenario for high temperature performance materials and and components

This project is funded by the European Union under grant agreement 958196.

Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union. Neither the European Union nor the granting authority can be held responsible for them.