Game of words: differences between accreditation, certification and homologation

- Accreditation: “is the international tool used to generate confidence in the correct performance of a very specific type of activity known as Conformity Assessment Activities, which include testing, calibration, inspection, certification and verification, among others. In general, any activity that assesses whether a product, service, system or installation conforms to certain requirements, can be subject to accreditation. These requirements may be stipulated by law and, therefore, be of a mandatory nature or be specified in standards, specifications or other documents of a non-regulated nature” (source: ENAC).

- Certification: It is the result of a process by which the auditors or evaluators of the certifying company examine the conformity of a specific product or service according to the requirements of the standard (various sources).

- Homologation: “It is the verification of the fulfilment of certain specifications or characteristics” by an organization or an official authority (source: AEC).

“Accreditations, certifications and homologations are a fundamental aspect for the metal-mechanical industry and for high-demand sectors such as automotive, aeronautical, railway, ship building, machine tool or the energy sector. All of them stand for significant Quality requirements.”

If these definitions still do not help us clarify whether our product, service or system is accredited, certified or homologated, we will explain them in another way to differentiate the concepts.

If an organization (understanding by organization any company, centre, institution, etc.) is accredited, it means that the requirements of the standard that apply to it have been verified and approved by an accreditation entity. Generally, there is a single accreditation entity at each country. This list compiled by European Accreditation gathers the main accreditation entities existing in Europe, by country.

In the same way, it is also called accreditation to the compliance of the international normative-administrative evaluation models of specific sectors, such as the aeronautical sector, with the NADCAP accreditation, or the railway sector, with the IRIS accreditation, among others.

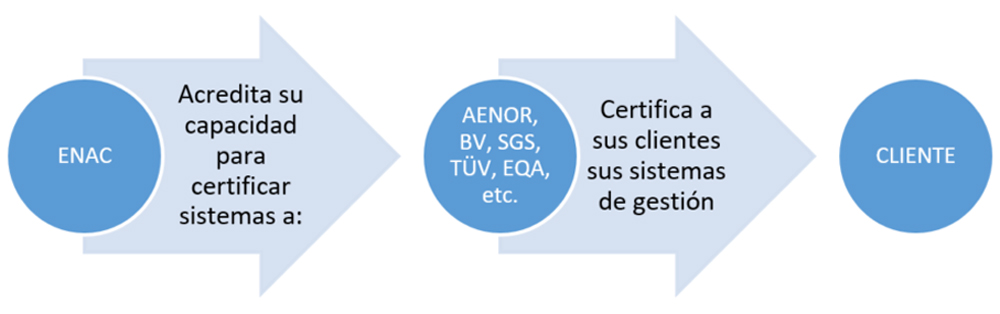

When an organization is certified, it means that the validation of the requirements of the standard applied to it have been checked and verified by a certifying entity. This certification entity must first have been previously accredited by an accreditation body that has verified and approved its competence to certify third parties. In this case, it is not unusual to have more than one certifying company per country. Among the best known entities near us we can find several, such as AENOR, BUREAU VERITAS, SGS, TÜV-RHEINLAND, EQA, etc.

Figure 1: Accreditation and certification cicle.

Finally, the homologation is generally obtained by means of an organization that requires specific conditions or specifications to be able to establish a working relationship with a supplier organization (of products or services). In this case, the applicable requirements are verified and approved by the customer´s organization. That is, the recipient of the product or service in question.

For sure, accreditations, certifications and homologations are a fundamental aspect for the metal-mechanical industry and for high-demand sectors such as automotive, aeronautical, railway, ship building, machine tool or the energy sector. All of them stand for significant Quality requirements.

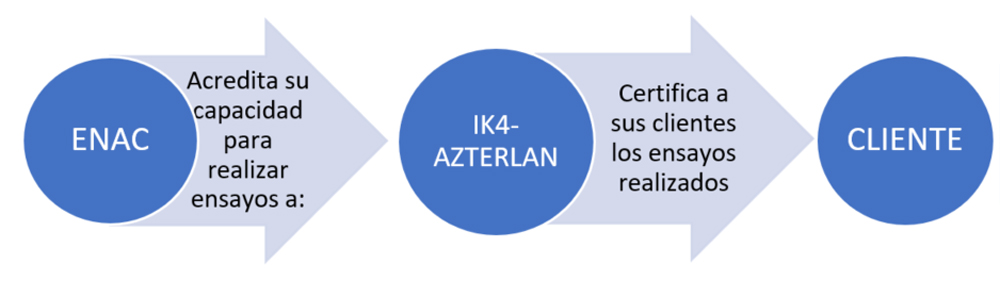

To help us illustrate how accreditations, certifications and homologations coexist, we can take as an example the case of the IK4-AZTERLAN Metallurgical Research Centre, which is:

- Accredited by ENAC to certify industrial tests such as mechanical properties, chemical analysis, metallographic characterizations, non-destructive and materials corrosion testing to the different customer organizations that require these characterizations, according to the UNE-EN ISO/IEC 17025 standard.

Figure 2: IK4-AZTERLAN Metallurgy Research Centre is accredited to certify its cliets’ testings

- Accredited by NADCAP to perform tests for the aeronautical sector as a “Materials Testing Laboratory”.

- Homologated by Airbus, Sikorsky and Renault, who guarantee to all their supply chain that the service offered by IK4-AZTERLAN stands for the requirements of its customers.