New heat treatments and study of the effect of Si on the behavior of Inconel® 718 at high temperatures

When it comes to heat treatments, it has been analyzed how the cooling rate of molds affects to heat treatments and how a pre-treatment prior to HIP affects the end result. The following fundamental effects have been observed:

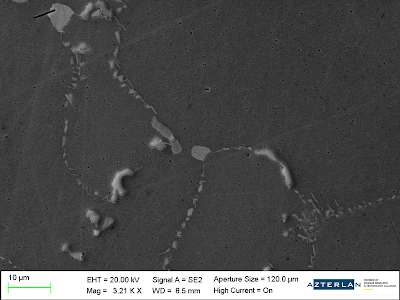

- When cooling rate is low, the amount of laves phases increases and a complete disolving is not guaranteed, after conventional HIP and homogenization treatment .

- The introduction of a Pre-HIP treatment (hot isostatic pressing) desingned by AZTERLAN, permits to reduce the presence of Laves fases at the end of conventional treatment. The result is an improved behavior at high temperatures (Gleeble).

- The cooling rate has been determined for this kind of ensayos Gleeble tests (loss of ductility above certain temperatures and temperatures to recover these propperties after heating the sample at high temperatures) in such a way that a greater grain size and the presence of a higher amount of Laves phases confirms the reduction of ductility in these alloys under mechanical testing with heating and cooling cycles.

When it comes to chemical composition of the alloy,

the amount of Si has been found to be key regarding mechanical propperties at high temperatures:

- The formation of a higher amount of Laves phases while silicon amount increases, not allowing their complete solubilization after heat treatments.

- The propperties of hot traction and Geeble testing have provided significantly improved results in low silicon alloys, in front of high silicon ones.

AZTERLAN Metallurgy Research Centre has significan capabilities oriented to the optimization of the characteristics of metallic alloys and components to provide a propper response in highly requiring applications. The development of new metallic materials, the optimizazion of manufacturing processes and the configuration of new products and application fields, are some of the working fields of AZTERLAN.

—————

(*) This study has been performed inside of HIPERTURB project oriented to the modification of manufacturing process of turbine components manufactured in IN718 to improve the service life of these parts and reduce potential faillures. pHIPERTURB has been funded by H2020 under Clean Sky JU program (H2020-CS2-CFP04-2016-02).