It is well known that the metallurgical quality and the nucleation potential of cast iron are influenced by a series of factors such as the metallic charge, the chemical composition, the liquid treatment (spheroidization and inoculation) and the melting, holding and pouring temperatures. From all of them, the spheroidization treatment supplies an important basis for the subsequent inoculation, providing a large number of potent nuclei for graphite. It plays an important role being responsible for the graphite crystallization in spheroids and consequently, for obtaining better mechanical properties. Ferrosilicon alloys, which usually contain from 3% to 9% of Magnesium along with some small additions of Al, Ca, La and Ce, are the most widely used for these specific treatments.

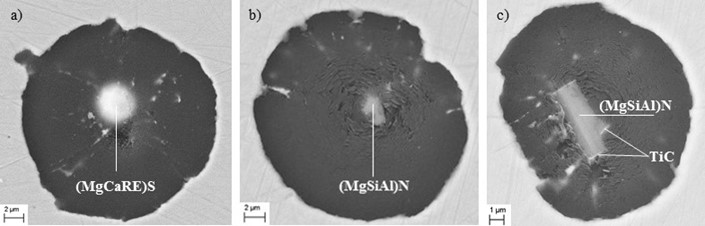

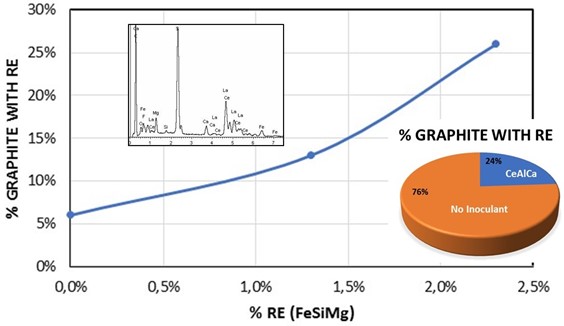

To further understand the influence of these elements on the nucleation of graphite, melts treated with 3 different magnesium treatments, whose main difference was the content of rare earths (RE) (without RE, 1.3% RE and 2.3% RE), were produced and poured into standard thermal analysis cups. An inoculant rich in Ce was also used (1.83% Ce, 0.95% Al, 0.91% Ca). After cooling to room temperature, the cups were sectioned and prepared for metallographic characterization to identify the nature of the inclusions which can act as nucleation sites for the graphite nodules through spectrums, mapping and line scans generated with a FEG-SEM equipment.

Results and discussion

A direct relation was found between the type of Fe-Si-Mg alloy used and the number of graphite with RE in the nucleus. The presence of sulfides seems to be linked to the type of nodularization treatment used, increasing with a higher content of RE in the Mg treatment alloy. Their dominance is improved by the lack of inoculation, which demonstrates the influence of the spheroidization treatment on the nucleation process. The explanation could be the excellent affinity between S and RE to form complex RE-sulfides. It is assumed that these compounds can act as excellent nucleation sites because of their values of two of the main requirements that a non-metallic inclusion must verify to act as a good nuclei: the energy of formation (4.07E+05 J/mol for CeS, 6.16E+05 J/mol for Ce2S3, -6.42E+05 J/mol for La2S3) and disregistry (2.9% for CeS, 1.5% LaS). The energies of formation are defined by the Ellingham´s diagram, so that, the lower they are, the more stable will be that compound and, therefore, more suitable for the formation of graphite. On the other hand, the disregistry is a parameter which measures the difference between the lattice parameters of the nucleant (sulfides in this case) and the nucleating solid (graphite). Low values of this variable indicate more similar crystalline structures of both solids favoring in this way the precipitation of graphite.

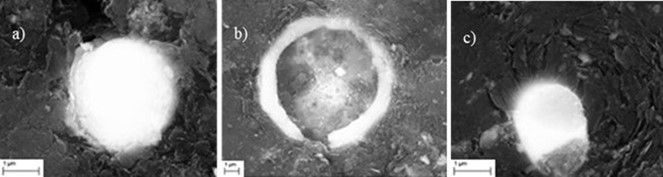

Figure 3: Distribution of RE in the nuclei: a) around all the inclusion; b) forming a shell; c) like a partial shell.

The main results of this investigation have been presented at the 12th International Symposium on the Science and Processing of Cast Iron (SPCI XII) which was celebrated on November 2021 in the city of Muroran (Japan).