EU funded project to develop Digital Materials for the automotive industry by connecting manufacturing/process data and the end characteristics of cast iron components.

Project completed

Start date

H2020

Funding

830903

Grant agreement number

End date

Electronics, the Internet of Things and smart systems are becoming extremely useful for many sectors and industries and are experiencing a rise in demand and interest across the globe. Among the sectors that are benefiting the most from the use of smart systems is the automotive industry.

This smart integration could allow for better communication between the manufacturing process and the development of materials. Unfortunately, the automotive industry still lags behind in terms of smart systems uptake. The EU-funded DigiMAT project will reverse this trend by introducing an innovative smart solution for connecting process and material characteristics to achieve a new generation of digital materials in the automotive industry.

Digital materials can have a wide impact in industry and society. The potential application to all type of material can render in significant global weight reduction in transport media and more sustainable development of industrial processes.

New digital materials for lightweight and more performant metallic components.

Related contents

Project goals

DigiMAT project is oriented towards developing a Smart solution for connecting process and material characteristics to achieve a new generation of digital materials in the automotive industry.

Its results will be demonstrated by developing a new brake system with an anchor at least 12.5 % lighter and a housing with 10% improved machinability.

The new developed solution will reach the 35% of the European iron foundry market, 10% of the Worldwide level iron foundry market.

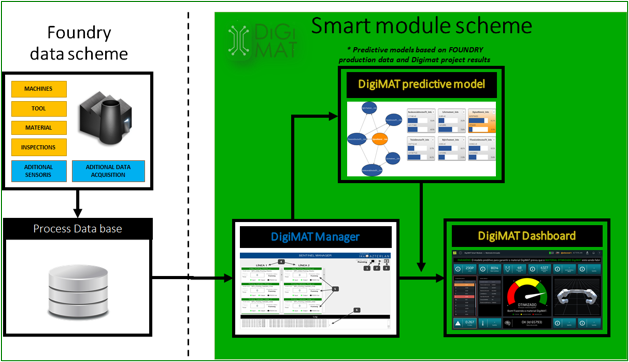

A new smart data management module “DigiMAT module” will be developed by one SME specialized in ICT solutions. Its development will be supported by a sensor network and an advanced data management system already running in the iron foundry company. This smart module will consist on a specific algorithm for each digital material development combined with an automatic protocol definitions system that will conform a specific methodology. It will acquire, store, process and analyze data coming from a previously defined set of trials.

Its validation will be completed with the homologation of new digital materials by the TIER 1 company and by their introduction in the foundry company portfolio. In parallel the TIER 1 company will develop a lighter anchor based on the developed high yield material. This lighter anchor integrated into a new brake system will be functionally homologated by the TIER 1 and final user (OEM). Finally, partners will commonly develop a business plan for quick take up of the project results.

Technical objectives

- Launch of the intelligent DigiMAT module to develop algorithms that connect process and material characteristics to achieve a new generation of digital materials.

- Increase global market rate by 3 %.

- Development of final components that are 3.5% lighter and at least 9 % less energy consuming.

- Provide melted iron products with easy machining characteristics and more competitive with a cost reduction of 3 %.

- Weight reduction will permit producing cars and other kind of vehicles with a higher energy efficiency while minimizing the weight and also the manufacturing costs.

- Intelligent manufacturing will permit achieving custom products and mass produced products.

- The tehnologies and tools born after this proposal will offer opportunities to employ highly qualified professionals.

- The novel technology has potential applications in other industries such as aluminum foundry and steel foundry.

Main results achieved

The DigiMAT project is called to have a high impact on all the partners of the consortium, and an expected a cascade impact on the EU industry, having its main influence on automotive sector.

The project will have direct impact on different applications initially where ductile iron and specific parameters are desired such as yield strength or machinability. Thus, different automotive components are related, and several European iron part manufacturing processes and end-users will receive a significant impact.

Main innovations achieved

Product data analysis based on statistical control tools and process adjustment based on human decisions is improved by “A digital prediction modelling based on the best combination of some mathematical models such as Artificial Neural networks, Bayesian Networks, Naïve Bayes, etc.”

Decission system is based on expert people and after data analysis is improved by “on-line intelligent system that allows to forecast the results and if unexpected deviation occurs, the new established actuations protocols are applied”.

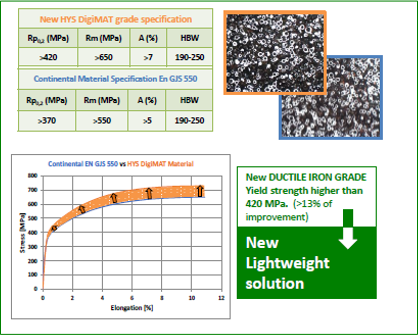

Existing cast iron manufacturing grades allows significant variation ranges in mechanical properties and thus high security coefficients are applied in the design phase of the components; are improved by “New cast iron grades with tailored made mechanical properties and with a reduced variation range”.

Many processes and product variables affecting machinability are unknown nowadays. In addition, machinability measurement is a difficult task. Thanks to DigiMAT the “expert knowledge on main process variables and product characteristics affecting machinability is defined and controlled by the SMART DigiMAT module. A significant improvement in machinability was observed at Continental facilities.

Main results achieved

- The smart module for digital materials manufacturing

- Actuation protocols and specific controls for tailor-made digital materials implementation

- Digital material 1: Cast iron grade with higher mechanical performance and the relevant manufacturing route

- Digital material 2: Cast iron grade with improved machinability, and the relevant manufacturing route

- Improved brake system, based on the new lighter anchor and cost-effective housing

Project Consortium

VEIGALAN STUDIO

PROJECT LEADER

AZTERLAN Metallurgy Research Centre

AAPICO Portugal

CONTINENTAL TEVES

This project has received funding from the European Union’s H2020 programme for research, technological development and demonstration under grant agreement No. 830903. H2020 EIC-Fast Track to Innovation-2018.