Development of new secondary alloys for the manufacture of ductile components by means of VHPDC technology

Optimization and implementation of Vacuum High Pressure Die Casting (VPDC or VHPDC) advanced technology is a relevant strategic research and development line of the aluminum and light materials area of the Azterlan Metallurgical Research Centre.

Refining companies, who market the secondary alloys after purchasing aluminum scrap, assure that Fe and Cu elements are their biggest difficulty to obtain secondary alloys that are close to the chemical composition of the AlSi10MgMn (ENAC 43,500) primary alloy. Other impurities (such as Zn, Cr, Ni, Pb, …. etc) are not so problematic.

Thus, there are many research works focused on improving the general metallic properties of secondary Al-Si alloys with high Fe content. Four different sorting methods that have been used to reduce the intermetallic and fragile β-Al5FeSi phases are:

1) Control of the Fe content. This method is based on the selection of raw materials with very low Fe content. Usually, primary Al-Si alloys have a 0.03%-0.15% Fe content, the average being 0,07%-0.10%. Nevertheless, the market of secondary alloys presents different levels of Fe content, being the price of the material a clear reference. Cheaper materials have a greater level of impurities.

3) Thermal interaction on the aluminium alloy. This method is based on two independent treatments.

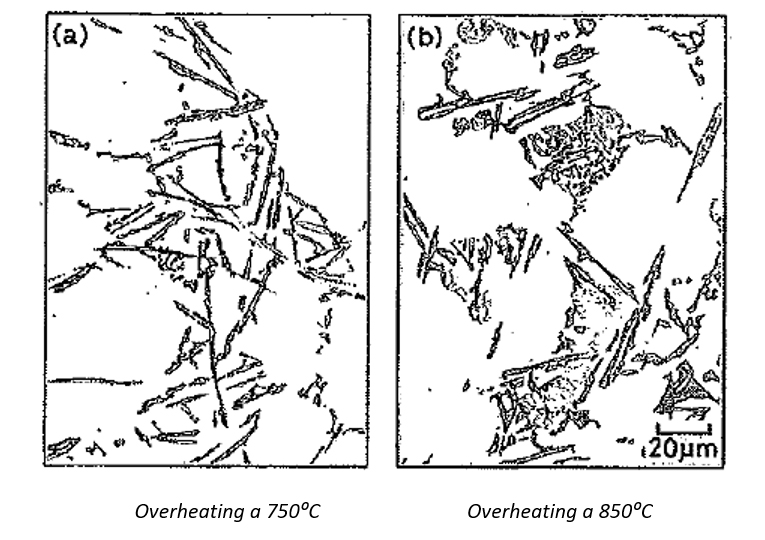

- Overheating: It is focused on leading the metal to a high temperature to reduce the nucleation of the compounds that form the ß-Al5FeSi intermetallic phases. The disadvantage of this method is that, by increasing the temperature, there is as well a potential risk of increasing the hydrogen content and the content of oxides in the metal. It also increases the process time and cost.

Figure 1.AlSi6Fe 0.4% alloy microstructures with overheating at 750⁰C and at 850⁰C

- Increasing the solidification speed. As described above, the higher the solidification speed is, the shorter and thinner the ß-Al5FeSi intermetallic phases. They even precipitate mostly in α -AlFeSi intermetallic phases if the solidification speed is high. This method is widely used in sand and shell moulding technology. Anyway, it cannot be used in the VHPDC technology because its solidification speed is already quite high.

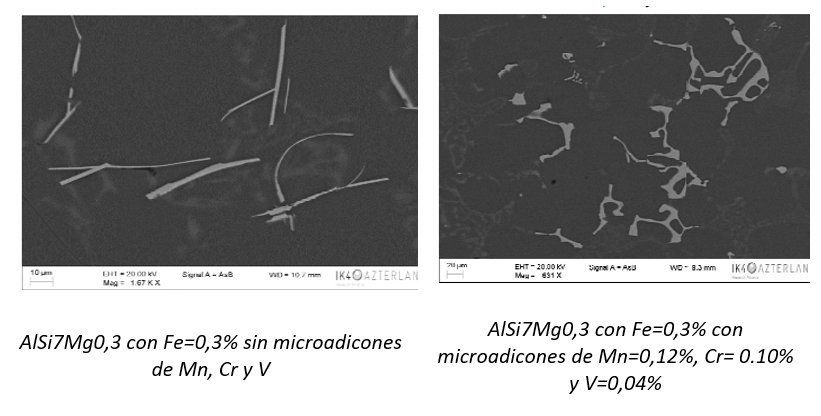

4) Chemical neutralization of the ß-Al5FeSi intermetallic phases. This neutralization is obtained by the micro-additions of different elements such as Mn, Cr, Sr, Be, V, Co, P, K and Be and the combinations of two or several elements. The effect of Mn and Cr and their combinations is described below.

- When it comes to the Mn, its use is widely extended and its content is related to Fe according to the following rule: %Mn>0.5 x Fe%. But the micro-addition of Mn must be optimized because, when the reduction of the ß-Al5FeSi phases are almost totally reduced, the α-AlFeSi intermetallic phases of polygonal or starred morphology considerably increase their size, decreasing the ductility of the alloy.

- Regarding Cr, its effects are similar to those of Mn. In the research carried out by the University of Padova together with the Metalli Capra refinery, in AlSi9Cu3 alloys with a high solidification speed such as those of the high pressure die casting the micro addition of Cr together with a high speed of solidification promotes the formation of primary Sludge compounds and intermetallic proeutectic phases α-Alx(Fe,Mn,Cr)ySiz and the fraction area of the high Fe intermetallic phases are increased as the Cr content in the alloy gets higher. The research work of Hyun You Kim, Sang Won Han and Hyuck Mo Lee also analysed the influence of the Mn and Cr combination. For a Fe content of 0.2% in A356 alloy, with a content of Cr=0.13% and Mn=0.13%, intermetallic α-AlFeSi phases of smaller size than those with only the 0.2% Mn addition were obtained. This fact is due to the Cr lower diffusion coefficient in comparison with Mn. Another research work carried out by the AZTERLAN Metallurgy Research Center shows that, in the sand moulding technology, an AlSi7Mg0.3 alloy with a Fe content of 0.3% and an optimised micro-addition of the Mn, Cr and V elements offers the same quality index than a AlSi7Mg0.3 primary alloy with a 0.09% Fe content. It is also remarked that, increasing the content of Mn, Cr and V above the optimum content, the Fe high intermetallic phases increase both size and fraction of area worsening mechanical properties. The transformation of the intermetallic ß-Al5FeSi phases is shown below in Figure 10 to α-AlFeSi phases increasing the content of Mn, Cr and V in the alloy:

Figure 2: Transformation of ß-Al5FeSi α-AlFeSi intermetallic phases for a same Fe content of 0.3%