-

Tags

If we would ask someone who is not familiar with the science of materials or the metallurgical industry what corrosion is, they might answer that corrosion is what makes iron become reddish. However, if the same person was asked about what the yield strength, the fracture toughness or the austenitic grain size are, he or she might stare at us wondering what kind of language we are speaking.

Most people know something about corrosion because most people have had to deal with it personally. It affects our cars, our appliances, the plumbing of our households, the planes we are taking to go on vacation …

Anyway, although we all know some way to define corrosion, very few people know how complex this phenomenon is. The following paragraph taken from the introduction of the ASM HANDBOOK VOLUME 13, a document that can be considered as a reference in the field of corrosion, can help us to get an idea:

Most people know something about corrosion because most people have had to deal with it personally. It affects our cars, our appliances, the plumbing of our households, the planes we are taking to go on vacation …

Anyway, although we all know some way to define corrosion, very few people know how complex this phenomenon is. The following paragraph taken from the introduction of the ASM HANDBOOK VOLUME 13, a document that can be considered as a reference in the field of corrosion, can help us to get an idea:

“PERHAPS THE MOST STRIKING FEATURE of corrosion is the immense variety of conditions under which it occurs and the large number of forms in which it appears. Numerous handbooks of corrosion data have been compiled that list the corrosion effects of specific material/environment combinations; still, the data cover only a small fraction of the possible situations (…). To prevent corrosion, to interpret corrosion phenomena, or to predict the outcome of a corrosion situation for conditions other than those for which an exact description can be found, the engineer must be able to apply the knowledge of corrosion fundamentals (…). Even with all the available generalized knowledge of the principles, corrosion is in most cases a very complex process in which the interactions among many different reactions, conditions, and synergistic effects must be carefully considered”.

The complexity of corrosion relies not only in the numerous variables that influence it, but also on its multiple ways of appearance. Therefore, its evaluation can be carried out in different ways also. Compared with other metallurgical tests, the corrosion tests are specific for certain materials, such as steel, aluminum or brass, as it affects each of them differently. Likewise, specific phenomena (such as intergranular corrosion, exfoliation or dezincification, respectively regarding the aforementioned) can be examined on each alloy. On the contrary, tensile tests for example, are similar for steel, aluminum or brass and tend to have a same purpose.

Although it is often said that corrosion is a natural phenomenon, few people really know how deep this true is. Indeed, the importance of corrosion is linked perhaps in its own nature, since the oxidation-reduction reactions that occur in metals are governed by thermodynamics at its purest and most basic level. It would seem unreasonable to say that life is not possible without the presence of corrosion, but at an atomic level it is just an electron transfer or exchange phenomenon that can be compared to other biological processes which are necessary for life. In fact, the red color of blood is due to the oxidation of the iron atoms that are part of the hemoglobin. Therefore, it is not possible to understand the extent of the corrosion phenomenon without keeping in mind that we also carry corrosion “in the blood”.

Sculpture “Heart of Steel” by Julian Voss-Andreae, material: Corten steel, representing hemoglobin molecule, just after installation, after 10 days of being installed and after several months of exposure. Source: https://scientiablog.com

The cost of corrosion

The effect of corrosion has been a problem since the first metallurgists began to melt and to transform metals several millennia ago and the fight against corrosion is not modern nor exclusive to the industrial era. There is evidence that in the middle ages artificial treatments were performed over elements made of copper and bronze to accelerate the formation of the patina surface coatings.

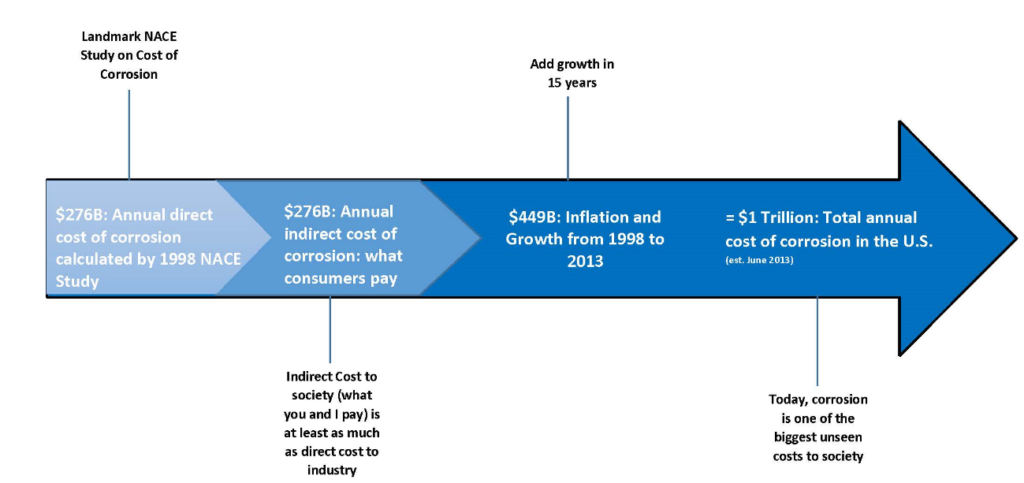

In the current industrialized world, corrosion is a phenomenon that affects all industrial sectors to a greater or lesser extent. It is difficult to precisely determine the economic cost that corrosion entails for a given industrial sector or for a country. One of the best known and most reliable studies carried out in this area, which even today settles a reference to get an idea of the economic cost of corrosion, was performed between 1999 and 2002 in the USA by various agencies, including NACE International (National Association of Corrosion Engineers). This study estimated that in 1998 the total cost of corrosion raised up to 276,000 million US dollars, approximately 3% of the GDP of the country.

It should be noted that this figure corresponds exclusively to the direct costs caused by corrosion, without considering the indirect costs that are necessary to avoid its initiation or propagation (such as maintenance, investments, … etc.). Considering these data and inflation over the years, it can be estimated that nowadays the cost of corrosion in the USA could reach 1 trillion USD.

In the current industrialized world, corrosion is a phenomenon that affects all industrial sectors to a greater or lesser extent. It is difficult to precisely determine the economic cost that corrosion entails for a given industrial sector or for a country. One of the best known and most reliable studies carried out in this area, which even today settles a reference to get an idea of the economic cost of corrosion, was performed between 1999 and 2002 in the USA by various agencies, including NACE International (National Association of Corrosion Engineers). This study estimated that in 1998 the total cost of corrosion raised up to 276,000 million US dollars, approximately 3% of the GDP of the country.

It should be noted that this figure corresponds exclusively to the direct costs caused by corrosion, without considering the indirect costs that are necessary to avoid its initiation or propagation (such as maintenance, investments, … etc.). Considering these data and inflation over the years, it can be estimated that nowadays the cost of corrosion in the USA could reach 1 trillion USD.

Estimation of annual cost of corrosion in USA.

Source: “Corrosion costs and Preventive Strategies in the United States” report by NACE International.

Source: “Corrosion costs and Preventive Strategies in the United States” report by NACE International.

However, corrosion not only entails economic costs, but also human costs. Several fatal accidents have occurred throughout history due to corrosion phenomena:

- Guadalajara, Mexico, 1992: a galvanic coupling between zinc-coated water system pipes and a steel gasoline pipeline produced corrosion by pitting and a perforation of the latter. The leakage of gasoline and a poor design of the sewer system caused the accumulation of gas, which led to a series of explosions that left more than 200 dead people.

- Switzerland, 1985: 12 people died because of the collapse of the roof structure of a swimming pool made of austenitic stainless-steel elements. The structure was weakened by chloride stress corrosion cracking.

- Bhopal, India, 1984: considered the most devastating industrial accident to date, more than 3000 people died directly from a methyl isocyanate leak from a pesticide factory. The use of unsuitable materials in various equipment and a lack of maintenance of the facilities produced the disaster.

These are just some examples of the devastating effects that corrosion can have but we do not have to go far back in time to find disasters. Last year (August 2018), the viaduct of a highway collapsed on its way through Genoa and although the cause is not directly attributable to corrosion, it is considered that it had a high degree of responsibility in the accident.

Ponte Morandi in Genoa, corrosion of the structural steel cables was one of the causes of the collapse. Source: https://www.cnn.com

Deterioration due to corrosion happens every day all over the world and in all sectors, but the ultimate responsibility for all these accidents is not just corrosion. The final cause of a failure, catastrophic or not, always obeys to the conjunction of diverse factors and among them, weakening of structures by corrosion plays an essential role. Design failures, service conditions more aggressive or severe than expected or the absence of proper maintenance works are just some examples of the long list of variables that can lead to corrosion and to a catastrophic incident.

Despite all these facts, accidents also help to improve designs, to develop new materials more resistant to corrosion or to implement detection tools and preventive actions that will allow to act before it is too late.

IK4-Azterlan Corrosion and Protection of Metallic Materials Department has a highly qualified and experienced team of experts in the analysis of pathologies and service-failures caused by corrosion. The cases studied by the team have usually caused economic losses and damages that entail the replacement of equipment, a greater number of maintenance shutdowns or even interrupting a productive process. The aim of this type of technological support is not just to find out the root cause of the failure but also to inform and to advise customers about possible alternative materials, designs, coatings, as well as any type of treatment with the purpose of improving the behavior of components or equipment, mitigating the final effects of corrosion.

Confronting an unknown enemy

There is only one thing more dangerous than the corrosion itself: the lack of knowledge about it. Corrosion is a discipline of the materials science where a serious lack of knowledge and information is very common in the industry in general.It is usual to receive requests to perform improper corrosion tests under specifications made of mixed standards with no sense and to know that some customer got surprised and disappointed by the fast deterioration of a certain material, or to be asked for an equivalence between testing-hours in a salt spray environment and performance-hours in real service without this being the aim of such test.

As we have already seen corrosion is a natural and inevitable phenomenon; therefore, it is important to be properly prepared to face it.

As a Technology Center committed to the generation and transfer of knowledge focused on metallurgy and on metallic transformation processes, corrosion is also an important field of study for IK4-Azterlan. In that direction we are constantly improving, not only our expertise and knowledge on how to fight against corrosion, but also on the way we help and assist the industry to do so.

As stated by Dr. Ian Malcolm in Jurassic Park: “Life always finds a way”. The same thing happens with corrosion as there is no human-created or designed system that can compete with the unpredictability of nature.

Author: David Sebastián