José Antonio Goñi

“The diagnosis of failures in service and the analysis of materials provide high-value information for the design and manufacturing processes of metallic parts.”

Metallurgy and Failure Analysis and Diagnosis

Analyzing the degree of technical cleanliness of components. Keys to successfully conducting the test

The “Technical Cleanliness Test of Components” or “Cleanliness Test” aims to ensure that, prior to

Materials for the energy of the future

Decarbonization & efficiency Materials for the energy of the future As the need to secure

Welding processes

field of expertise WELDING PROCESSES Advanced inspecion and characterization of weldings and welded elements We

Electrical conductivity and resistivity

Characterization test Electrical conductivity Characterization of the electrical conductivity and resistivity properties of metallic materials

Fatigue and fracture mechanics

Specialization field Detection, characterization and evolution of fatigue cracks Fatigue and fracture mechanics testing Certification

RADIOGRAPHIC INSPECTION

FEATURED TEST RADIOGRAPHIC INSPECTION High-precision 2D images to ensure the soundness of metallic components. More

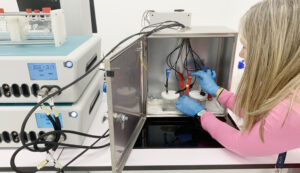

Hydrogen permeation assessment

ADVANCED CHARACTERIZATION HYDROGEN PERMEATION ASSESSMENT A key study to develop materials and coatings that are

Do NDTs provide actual measurements of defects?

A common question that we usually receive at the Non-Destructive Testing area of AZTERLAN is

Fastening elements

Specialization field Threaded fastening elements Quality assesment and characterization of screws, nuts, washers and threaded

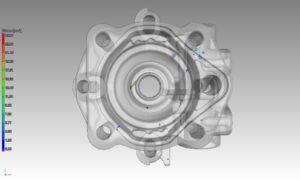

Axial Computer Tomography

FEATURED TEST AXIAL COMPUTED TOMOGRAPHY 3D representation of the soundness of metallic components. More information

Diagnosis and failure analysis

field of specialization Diagnosis and Failure Analysis Forensic study of the origin of in-service failures,

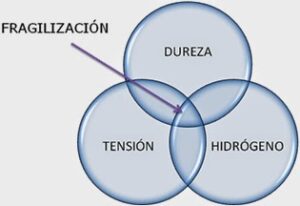

Hydrogen embrittlement

The identification of a failure of hydrogen embrittlement in a metallic component is often relatively