On World Materials Day 2022 AZTERLAN wants to showcase the oportunities presented by this promising material “to overcome the mistrust and limits that its use currently presents for certain applications, by developing new recovery and application technologies”.

Undoubtedly, aluminum is one of the most widely used materials worldwide to manufacture all kinds of products and components. Due to the mechanical characteristics offered by this material and its low density, aluminum has kept gaining more and more ground within the automotive industry, pressured to lighten the weight of vehicles while offering the highest safety standards.

However, as contextualized by PhD. Asier Bakedano, Head of Light Materials at AZTERLAN, the production of aluminum from bauxite is a process of high energy and environmental cost. “On the one hand, we have the extraction process of the bauxite mineral, which can mainly be found in countries such as Australia, China, Guinea, Brazil, Russia, … Once bauxite is obtained, it undergoes a chemical process (Bayern process) through which alumina is obtained; finally, the transformation of alumina into pure aluminium is carried out by an electrolytic process of high energy cost (Hall-Heroult process)”. Following this operations, 4.6 tons of bauxite are needed to obtain one ton of pure aluminum, also known after primary aluminium.

However, aluminum has another notable quality: it is infinitely recyclable. In this way, at the end of the useful life of the components manufactured in this material, the aluminum present in them can be recovered and reused once and again. The aluminum obtained from scrap is known as second-melt aluminum or secondary aluminum. “Secondary alloys are characterized by containing impurities and traces of other elements in their chemical composition. This is a handicap to use it in some applications because it affects the properties of the material”. Currently, secondary aluminium alloys are mainly used by die-cast iron sector where these impurities, such as iron, prevent the material from adhering to the tooling. “However, we must bear in mind that some trace elements also bring positive characteristics. Thus, an addition of copper, for example, will offer a greater hardness”.

From a yield standpoint, “up to 98% of aluminum scrap can be converted into secondary aluminum (in front of the 3.8 t of slag generated during bauxite processing)”. Therefore, while the production of primary aluminum has an energy consumption of 17000 kW t/hour and emits 6.6 kg of CO2 for each kg of aluminum produced, the production of secondary aluminum consumes 810 kW t/h and less than 0.5 kg of CO2 are emitted into the atmosphere to produce the same amount of material.

Aluminum lifecycle. A material with an infinite life

For all these reasons the presence of secondary aluminum has augmented significantly in the last years, and the main automotive manufacturers are requiring their TIER 1 supply chain (and these to their TIER 2) certain secondary aluminum targets to be incorporated into their production; “and this figure must keep growing”. To this end, “it is necessary for the industry to understand that secondary aluminum is not a problematic material when it is required to offer such demanding properties as ductility or elongation.”

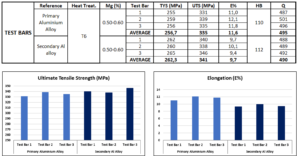

The evolution in the manufacture and treatment of molten metal “has brought us to a scenario that allows us to work with higher ratios of secondary aluminum. Thanks to a greater control of the production process and its metallurgical quality we can guarantee secondary aluminum to offer mechanical properties similar to those of primary aluminum in manufacturing processes like gravity die casting, low pressure die casting, forging, extrusion, etc. This fact also opens the doors to the incorporation of new alloys, with higher levels of impurities, to safely manufacture a wide range of components”. In addition, as the AZTERLAN researcher emphasizes, “to keep advancing in this way we also have the invaluable aid of simulation tools that help us predict and evaluate the behavior of components manufactured with different alloys fostering the development of new alloys and components with greater safety”.

However, Bakedano also highlights a fundamental area on which “it is essential to act” to ensure the characteristics of secondary alloys: proper separation and classification of waste (scrap). “Only by properly separating the aluminum waste streams at their source we will be able to secure higher levels of purity and/or chemical compositions suitable for different applications that require fewer alloy adjustments (either by adding pure aluminum or other elements). Avoiding the downgrading of recovered materials is a critical field of work for the metal recovery industry if secondary aluminium is to have the place it deserves as a manufacturing material for the advanced components of the future.”

Comparison between properties offered by primary aluminum and secondary aluminum developed by means of AZTERLAN methodology

The AZTERLAN Metallurgy Research Centre has been working for more than 15 years on strategies to recover and reuse secondary aluminum through the development of new metallurgical knowledge, innovative methodologies and ad-hoc equipment that favor the promotion of this sustainable material of the future.